Full-dry dust removal system for converter primary flue gas high-efficiency energy-saving ultra-clean emission

A high-efficiency, energy-saving, dust-removing system technology, applied in the field of dust-removing systems, can solve problems such as high requirements for operation and maintenance personnel, prominent smoke plume problems, waste of resources, etc., to avoid smoke plume problems, meet dust removal process requirements, and reduce corrosion problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

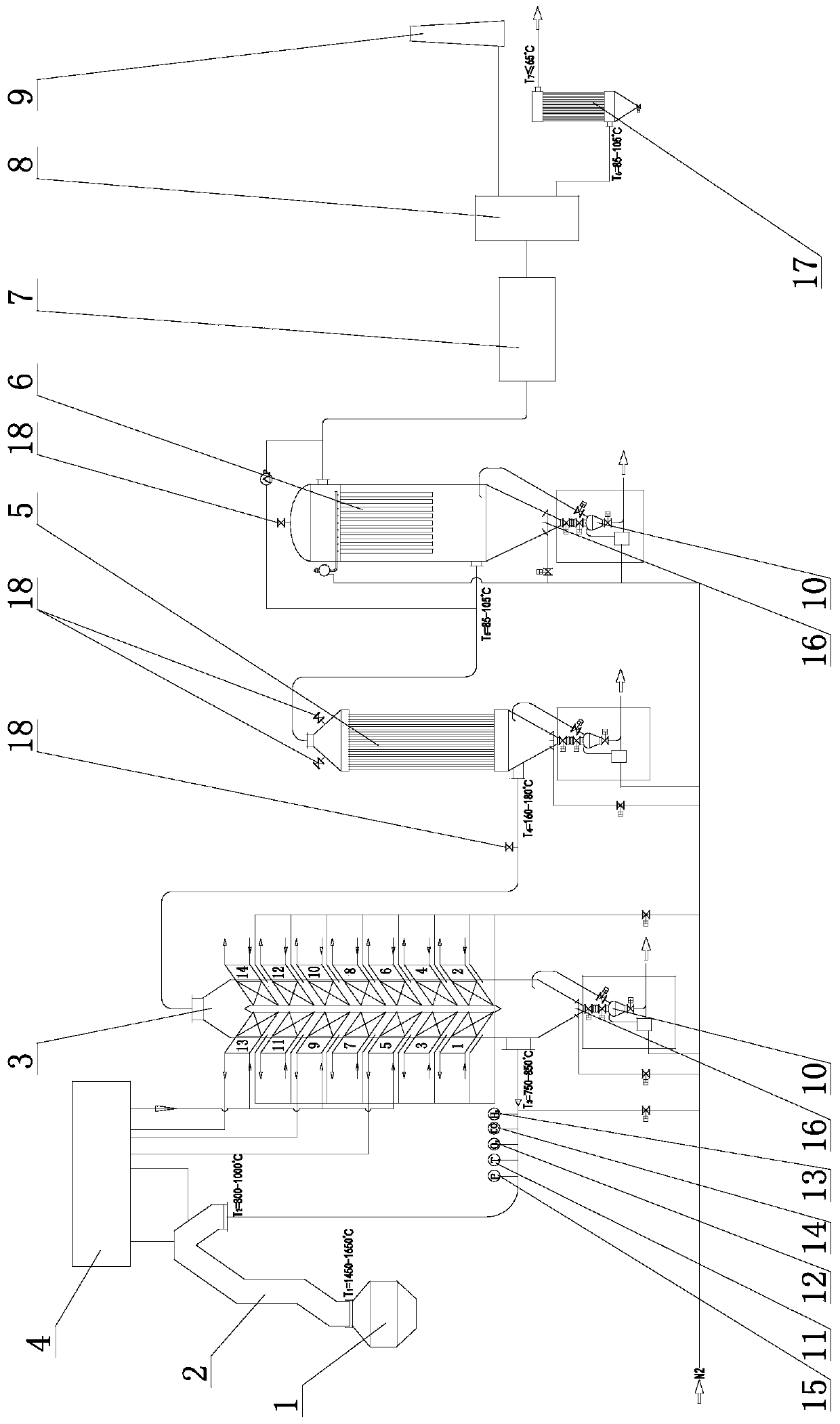

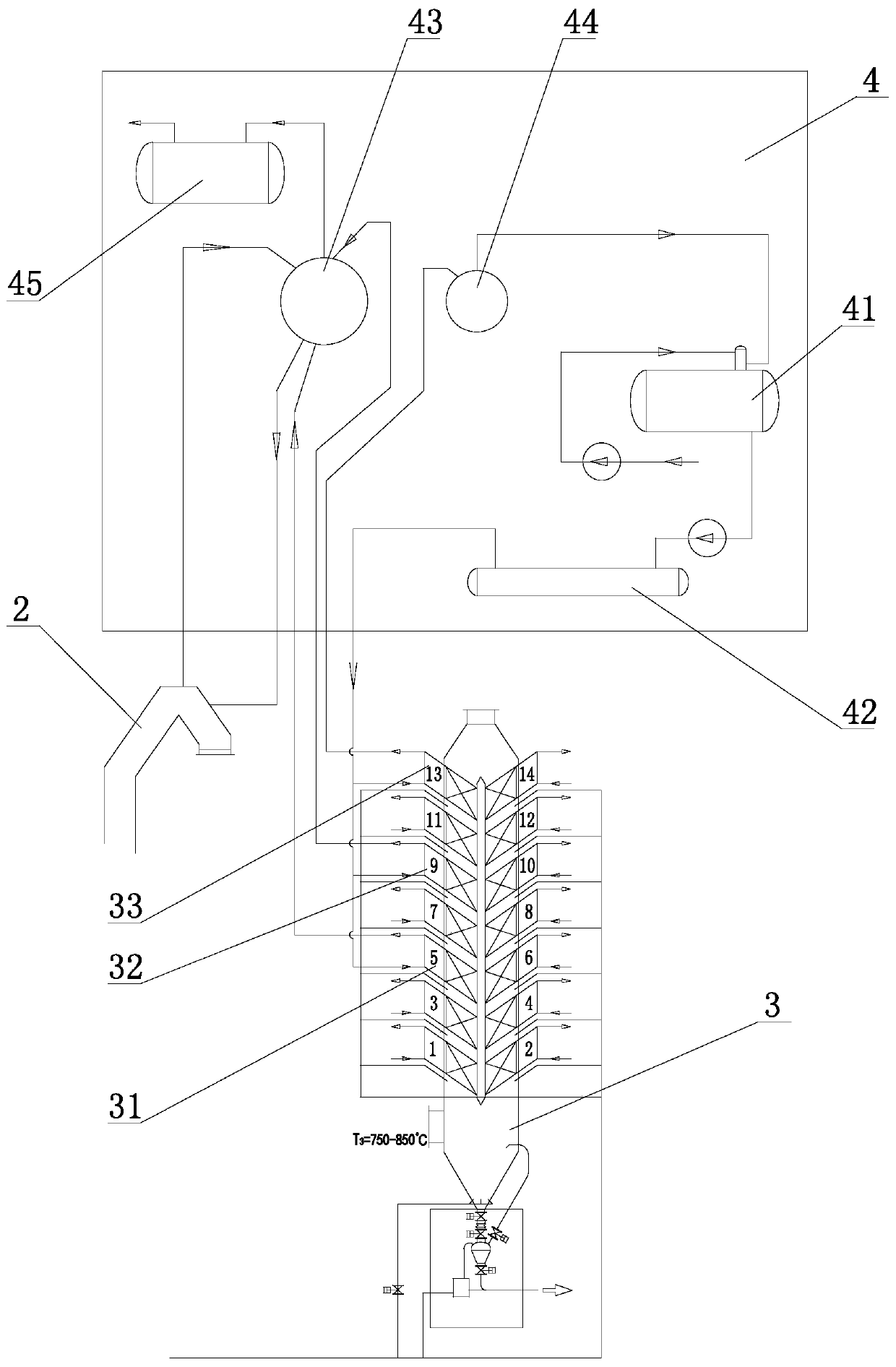

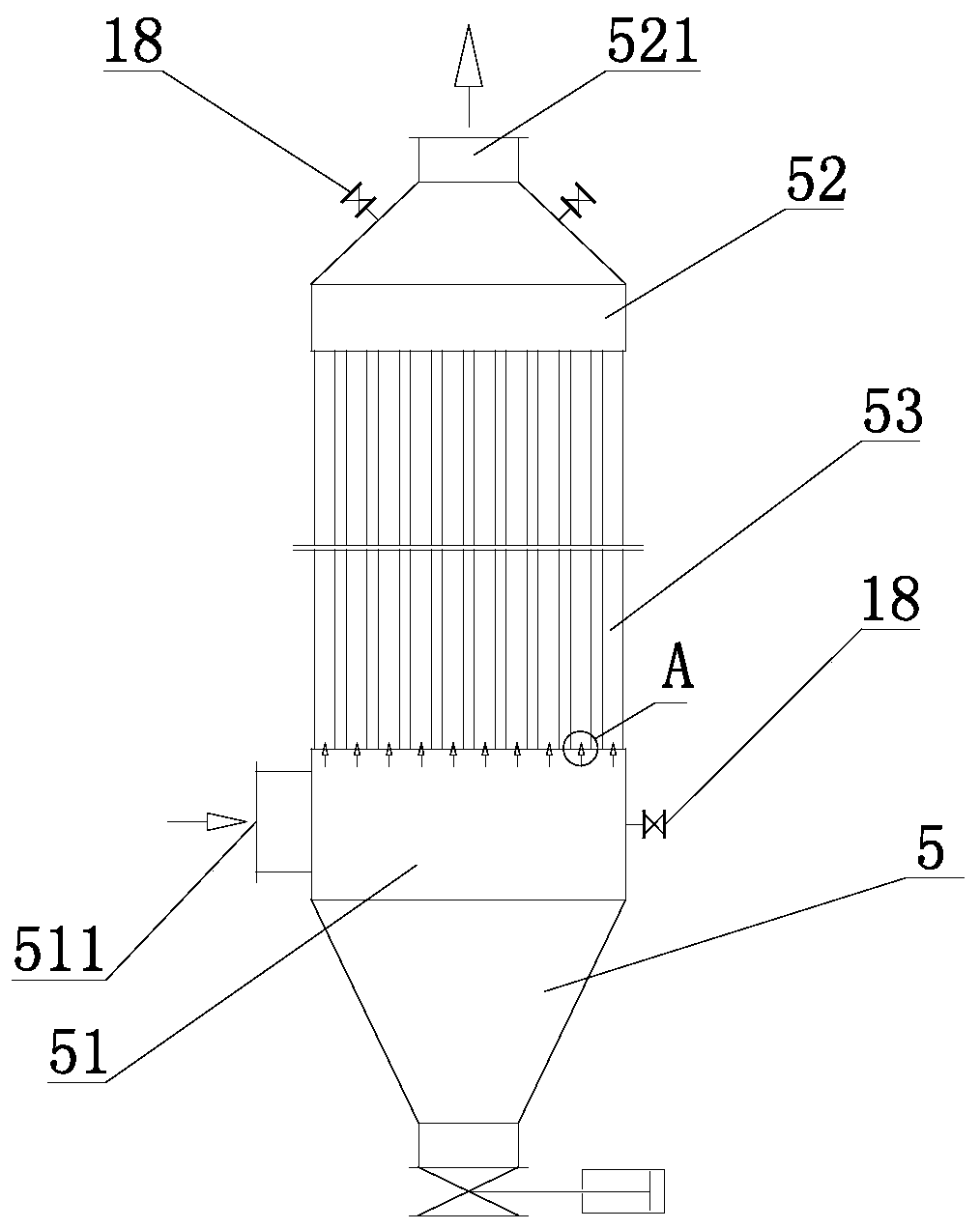

[0043] Such as Figure 1 to Figure 4 As shown, the full-dry dedusting system for the high-efficiency, energy-saving and ultra-clean discharge of the primary flue gas of the converter, the converter 1 is connected to the vaporization cooling flue 2, the vaporization cooling flue 2 is connected to the heat pipe waste heat boiler 3, and the heat pipe waste heat boiler 3 includes the heat pipe waste heat boiler 3 arranged in sequence from bottom to top High-pressure evaporator 31, economizer 32, and low-pressure steamer 33, vaporization cooling flue 2, high-pressure evaporator 31, economizer 32, and low-pressure steamer 33 are connected to waste water steam system 4, and heat pipe waste heat boiler 3 passes through the flue gas pipeline in sequence Connect the multi-tube explosion-proof flame arrester 5, the pulse bag filter 6, the fan 7, the switch station 8 and the chimney 9, the switch station 8 is also connected to the gas cabinet, the heat pipe waste heat boiler 3, the multi-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com