A Method for Quickly Restoring the Impact Toughness of Aging Nuclear Reactor Pressure Vessels

A technology for pressure vessels and nuclear reactors, applied in the field of rapidly reducing the number density of nanoclusters and restoring the impact toughness of aging pressure vessels, can solve the problems of high working temperature, complicated operation, expensive equipment, etc. The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, the pulse current treatment is performed on the small-sized aging simulated steel. Specific steps are as follows:

[0021] Step 1: Make pulsed samples. Take a 25mm×5mm×0.5mm aging sample, and polish the surface with 600, 1500, and 2000-grit sandpaper in turn until there are no visible defects to ensure good contact with the pulse electrode.

[0022] Step 2: Determine the pulse processing parameters. The parameter range of the pulse current is set, and the pulse current parameters are determined to be 400Hz, 190μs, 100A, and the action time is 15min.

[0023] The third step: pulse current treatment. Fix the small-sized sample after grinding on the output end of the pulse power supply with a fixture, and perform pulse current treatment on it for 15 minutes at room temperature.

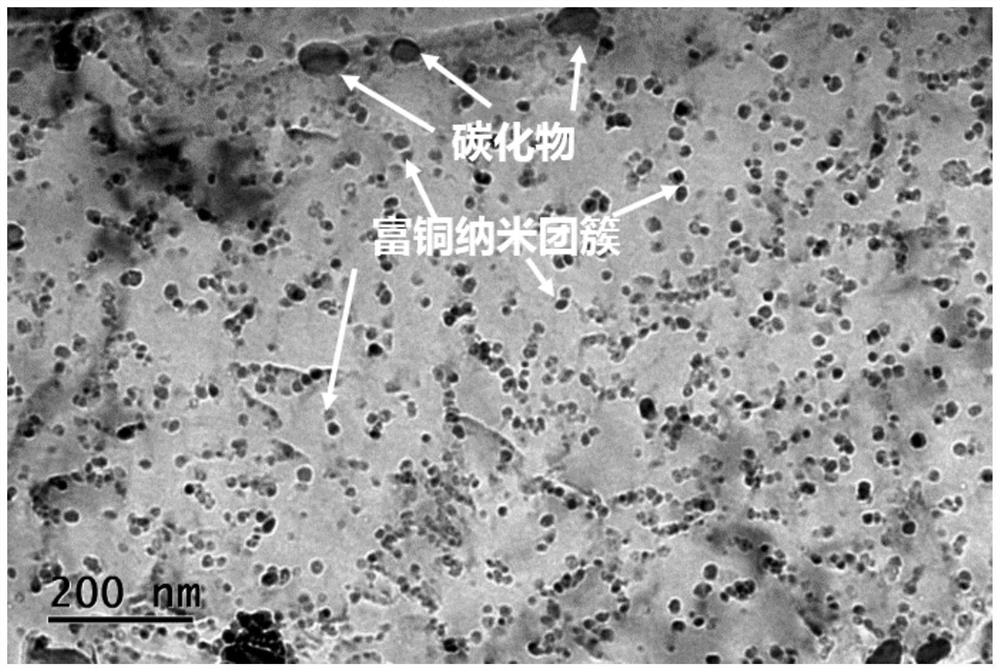

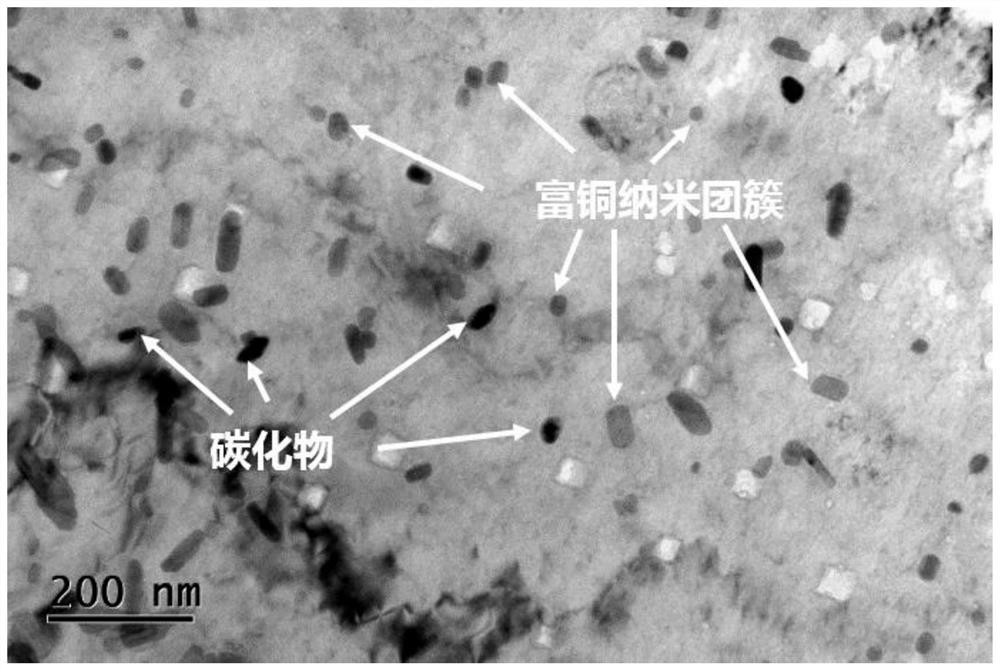

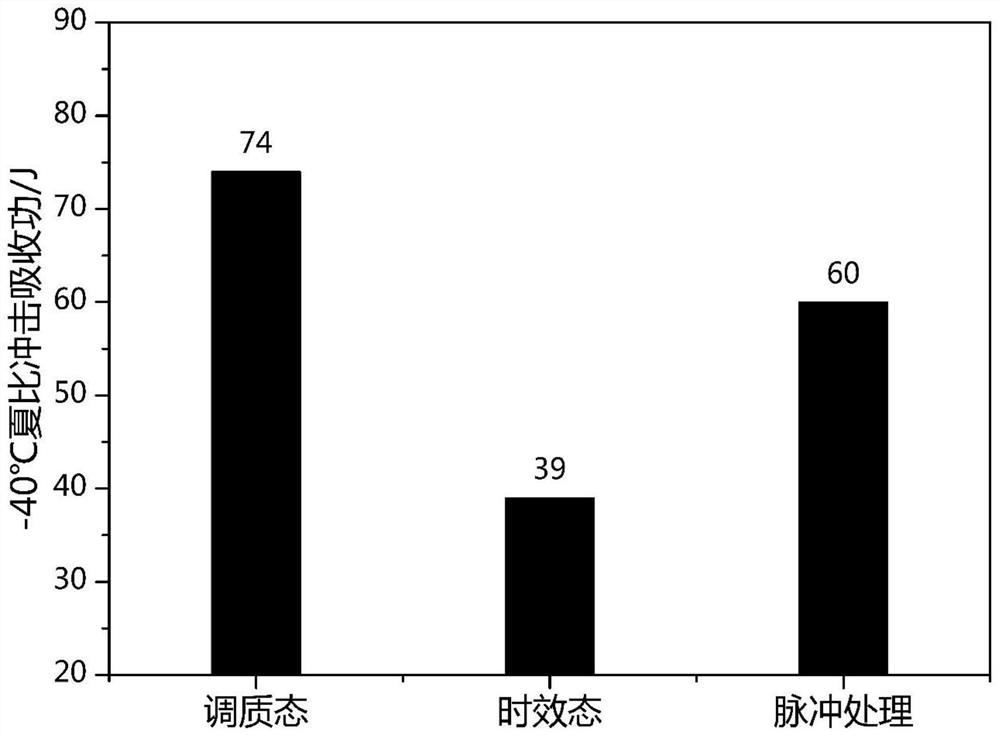

[0024] Step 4: Observing the distribution of copper-rich nanoclusters with a transmission electron microscope. Take the arbitrary position of the aging sample and the 10mm...

Embodiment 2

[0027] In this embodiment, the pulse current treatment is performed on the small-sized aging simulated steel. Specific steps are as follows:

[0028] Step 1: Make pulsed samples. Take a 25mm×5mm×0.5mm aging sample, and polish the surface with 600, 1500, and 2000-grit sandpaper in turn until there are no visible defects to ensure good contact with the pulse electrode.

[0029] Step 2: Determine the pulse processing parameters. The parameter range of the pulse current is set, and the pulse current parameters are determined to be 800Hz, 55μs, 200A, and the action time is 15min.

[0030] The third step: pulse current treatment. Fix the small-sized sample after grinding on the output end of the pulse power supply with a fixture, and perform pulse current treatment on it for 15 minutes at room temperature.

[0031] Step 4: Observing the distribution of copper-rich nanoclusters with a transmission electron microscope. Take the arbitrary position of the aging sample and the 10mm ...

Embodiment 3

[0034] In this embodiment, the pulse current treatment is performed on the large-scale aging simulated steel. Specific steps are as follows:

[0035] Step 1: Make pulsed samples. Take a 55mm×10mm×6mm aging sample, and polish the surface with 600, 1500, and 2000-grit sandpaper in sequence until there are no visible defects to ensure good contact with the pulse electrode.

[0036] Step 2: Determine the pulse processing parameters. Set the parameter range of the pulse current, and determine the pulse current parameters as 195Hz, 195μs, 200A, and the action time is 60min.

[0037] The third step: pulse current treatment. The polished sample was fixed on the output end of the pulse power supply with a fixture, and it was subjected to pulse current treatment for 60 min at room temperature.

[0038] Step 4: Observing the distribution of copper-rich nanoclusters with a transmission electron microscope. Take the arbitrary position of the aging sample and the 10mm area of the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com