Plant urease catalysis and grass planting combined sand stabilization method

A sand-fixing method and a plant urease technology are applied in chemical instruments and methods, land preparation methods, fertilizer mixtures, etc., and can solve the problems of low activity of soybean urease, complicated operation process, flammable acetone solvent, etc., so as to improve the solidification effect and the process is simple. , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing calcium carbonate by directly extracting plant urease from soybeans, the steps are as follows:

[0025] 1) Preparation of soybean flour: crush soybeans, pass through a 100-mesh sieve to obtain soybean flour, refrigerate at 4°C, and set aside;

[0026] 2) Extract urease: mix the two according to the volume ratio of soybean powder and distilled water at 1:10, add 3% trehalose of soybean powder at the same time, shake well and store at 4°C for 24 hours, at 3000 r / min After centrifugation for 15 min, the supernatant obtained by filtration is the urease solution, and the activity of urease is determined;

[0027] 3) Take the urease solution obtained in step 2) to prepare a urease solution with an activity of 4000U / L, take 50mL of the urease solution, add 1% Al 2 o 3 And stir evenly, mix with equal volume of gelling liquid, and spray into the tray covered with aeolian sand. Wherein, the gelling solution is a mixed solution of 0.75 mol / L urea and 0.75...

Embodiment 2

[0029] Embodiment 2 compares the impact of different processes on the calcium carbonate precipitation yield

[0030] Schemes 1-7 control different solid-liquid ratios (the solid-liquid ratios mentioned here refer to step 2, the mass ratio of soybean flour to distilled water volume) and contrast the concentration of gelling liquid to study the influence of different processes on the precipitation yield of calcium carbonate.

[0031] In step (2), the two are mixed according to the mass ratio of soybean flour to distilled water volume of 1:6, 1:8, 1:10, 1:12, 1:14.

[0032] In step (3), 50mL of urease extract was sprayed on the surface of drift sand, and then 50mL of different gelling solutions were sprayed, and the rest were the same as in Example 1. The results are shown in Table 1:

[0033] Table 1

[0034]

[0035] The results in Table 1 show that the concentration of the gelling solution is constant, and as the solid-liquid ratio increases, the precipitation of calcium c...

Embodiment 3

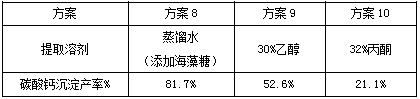

[0036] Embodiment 3: compare the impact of different extraction solvents on the calcium carbonate precipitation yield

[0037] Schemes 8, 9, and 10 compare the effect of different extraction solvents on the yield of calcium carbonate precipitation.

[0038] In step (2), the two are mixed according to the mass ratio of soybean flour to different extraction solvents at a volume ratio of 1:10.

[0039] In step (3), 50 mL of urease extract was sprayed onto the surface of the drift sand, and the remaining contents were the same as in Example 1. The results are shown in Table 2. It can be seen that the calcium carbonate precipitation yield obtained by extracting urease with trehalose-added distilled water was higher than 30% % ethanol and 32% acetone, and distilled water is used as the extraction solvent, which is economical and environmentally friendly, and is easy to use in the actual engineering site. Therefore, distilled water is selected as the extraction solvent.

[0040] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com