A preparation method of self-assembled prevascularized stem cell membrane

A cell membrane, pre-vascular technology, applied in medical science, prosthesis, etc., can solve the problems of cell necrosis, unable to form tissue regeneration effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

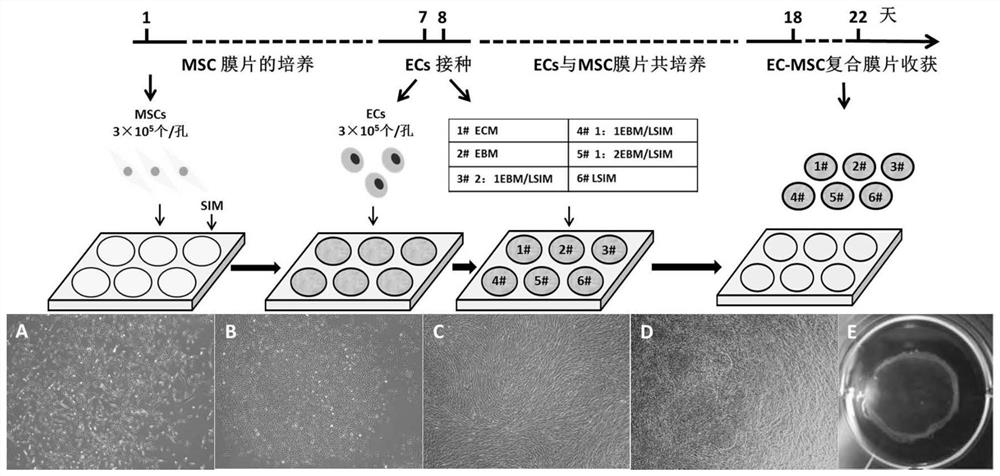

[0027] Example 1 Construction of vascularized EC-BMSC membrane

[0028] 1. Isolation, culture and identification of hBMSC

[0029] Use the whole bone marrow adherent method to isolate and culture hBMSC: Take fresh aseptic bone marrow, add an equal amount of PBS to mix, centrifuge at 800 rpm for 5 minutes, discard the supernatant, wash three times, add 15% fetal bovine serum and 0.4mg / mL of glutamine-based α-MEM medium, inoculated in 75 cm 2 in a culture bottle. After 3 days, half of the medium was changed for the first time, and then a new medium was replaced the next day to remove unadhered cells, and the adherent cells were continued to be cultured. The medium was changed every 2 days. When the cells grew to cover about 80% of the culture flask, they were digested with 0.25% trypsin and subcultured. Cells of passage P4-P5 were selected for subsequent operations.

[0030] 2. Isolation and culture of hUVEC

[0031] Take a sterile free umbilical cord, separate the umbilic...

Embodiment 2

[0040] Example 2 In vitro and in vivo functional evaluation of vascularized EC-BMSC composite membrane

[0041] 1. Construction of vascularized EC-BMSC composite membrane

[0042] The construction of the vascularized EC-BMSC composite membrane is the same as that in Example 1.

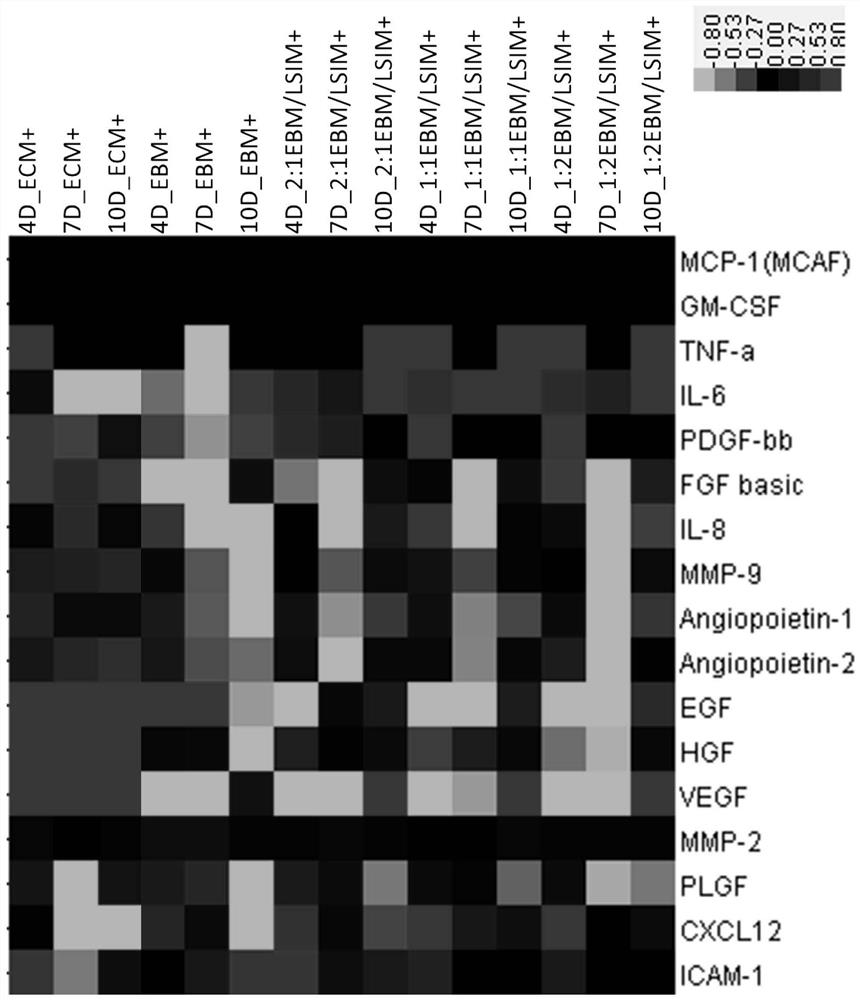

[0043] 2. Protein microarray analysis of supernatant of co-cultured cells

[0044] The cell supernatants of the co-culture system at different time points (3 days, 7 days, 10 days) were collected, and protein microarrays were used to analyze the differences in the expression of related secretory proteins (Table 2) in the co-culture supernatants. The results are as follows image 3 Shown: EGF, HGF, FGF, VEGF, Ang-1, Ang-2, MMP-9, IL-8 were highly expressed in the supernatant of group 1# added with exogenous growth factors. On the one hand, the high content of exogenous VEGF factors will transform vascular endothelial cells into a large number of tip cells, resulting in excessive sprouting of blood ves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com