A kind of foaming thermoplastic polysiloxane-polyurethane block copolymer and its preparation method and application

A technology of block copolymer and polysiloxane, which is applied in the field of foaming thermoplastic polysiloxane-polyurethane block copolymer and its preparation, can solve the problems of poor tensile strength and tear strength, poor skin-friendly property, mechanical Poor performance and other problems, to achieve the effects of penetration resistance mechanical properties, excellent skin-friendly properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

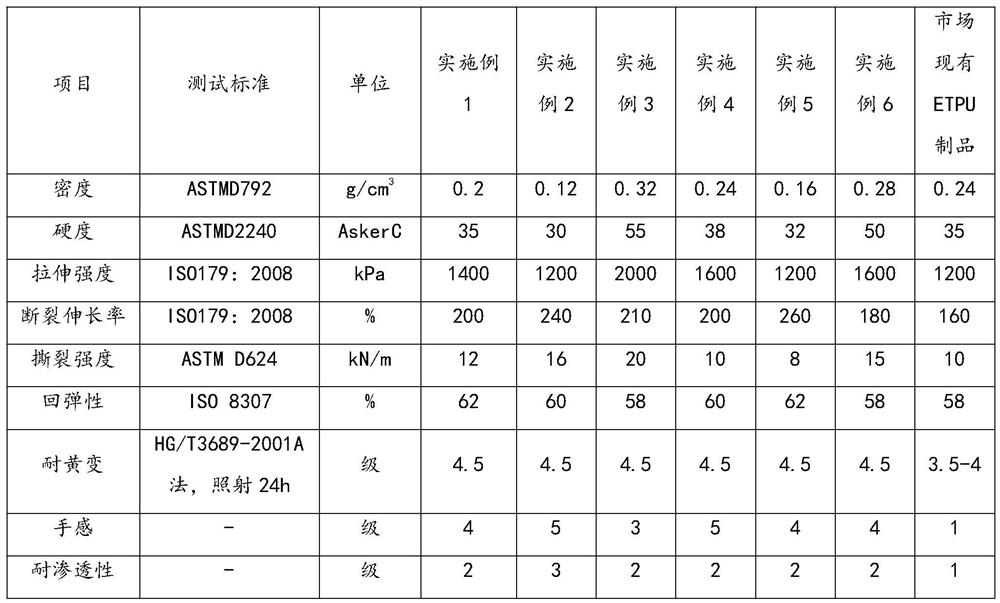

Examples

Embodiment 1

[0020] Add 1000g of thermoplastic polysiloxane-polyurethane block copolymer, 400g of carbon dioxide and 2000g of water into a 50L autoclave to form a suspension, then raise the temperature to 120°C, keep the pressure at 90bar, and discharge the suspension in the pressure vessel In the atmospheric environment, dry treatment to obtain a foamed thermoplastic polysiloxane-polyurethane block copolymer, which has a density of 0.18g / cm after testing. 3 . The thermoplastic polysiloxane-polyurethane block copolymer used therein contains an organosilicon block structure, and the number average molecular weight of the organosilicon block is 2000g / mol, and the silicon element content of the thermoplastic polysiloxane-polyurethane block copolymer is It is 10wt%, the rheological softening point is 100°C, and the hardness is 80ShoreA.

[0021] The foamed thermoplastic polysiloxane-polyurethane block copolymer obtained above was filled into a mold having a length of 300 mm x a width of 250 m...

Embodiment 2

[0023] Add 1000g of thermoplastic polysiloxane-polyurethane block copolymer, 250g of butane and 5000g of water into a 50L autoclave to form a suspension, then raise the temperature to 80°C, keep the pressure at 150bar, and keep the temperature and pressure for 180 minutes. The suspension in the pressure vessel is discharged into the atmosphere, and dried to obtain a foamed thermoplastic polysiloxane-polyurethane block copolymer, which has a density of 0.05g / cm after testing. 3 . The thermoplastic polysiloxane-polyurethane block copolymer used therein contains an organosilicon block structure, and the number average molecular weight of the organosilicon block is 5000g / mol, and the silicon element content of the thermoplastic polysiloxane-polyurethane block copolymer is 0.5wt%, the rheological softening point is 70°C, and the hardness is 30ShoreA.

[0024] The foamed thermoplastic polysiloxane-polyurethane block copolymer obtained above was filled into a mold having a length of...

Embodiment 3

[0026] Add 1000g of thermoplastic polysiloxane-polyurethane block copolymer, 1000g of nitrogen and 1000g of water into a 50L autoclave to form a suspension, then raise the temperature to 180°C, keep the pressure at 10bar, and reduce the pressure after 90 minutes at constant temperature and pressure The suspension in the container is discharged into the atmosphere, and dried to obtain a foamed thermoplastic polysiloxane-polyurethane block copolymer, which has a density of 0.5g / cm after testing. 3 . The thermoplastic polysiloxane-polyurethane block copolymer used therein contains organosilicon block structure, and the number average molecular weight of the organosilicon block is 300g / mol, the silicon of thermoplastic polysiloxane-polyurethane block copolymer The element content is 30wt%, the rheological softening point is 170°C, and the hardness is 100ShoreA.

[0027] Stir 100g of the foamed thermoplastic polysiloxane-polyurethane block copolymer obtained above, 30g of PU envir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com