Composite nano-coating material with hydrophobic and anticorrosive performances, and preparation method and application thereof

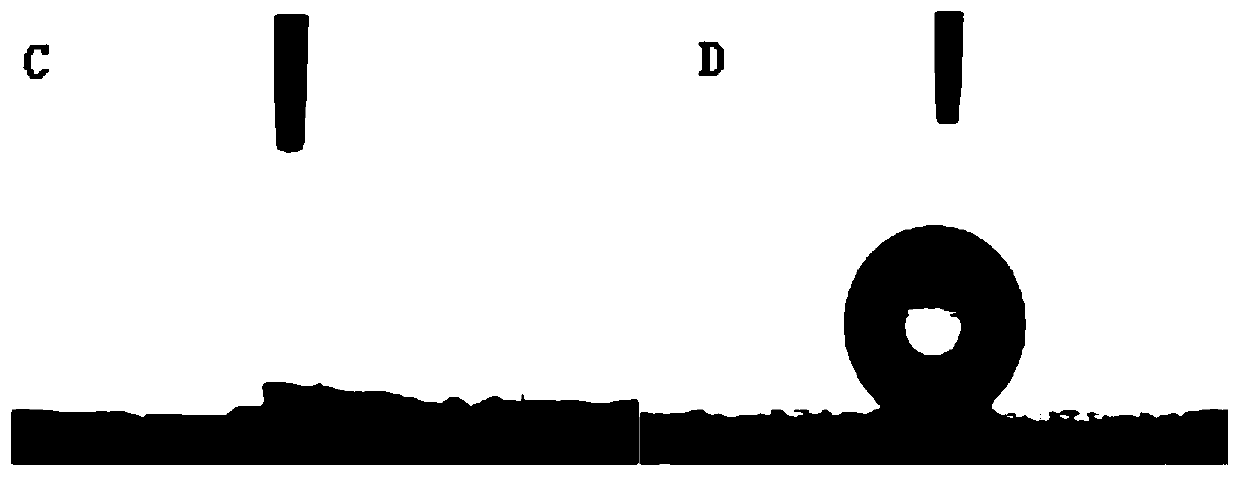

A nano-coating, hydrophobic technology, used in anti-corrosion coatings, coatings, epoxy coatings, etc., can solve the problems of poor mechanical properties, large amount of fillers, poor anti-corrosion effect, etc., to improve water vapor resistance and anti-corrosion performance. , the effect of enhancing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052]Example 1, weigh 200 mg of graphene oxide powder and place it in 200 ml of absolute ethanol solvent, and ultrasonically disperse for 2 hours to obtain a reaction solution. Add 1.0 g of tetraethyl silicate and 0.5 g of heptadecylfluorodecyltrimethoxysilane to the reaction solution, and at the same time add 2 to 3 drops of acetic acid as a catalyst, and stir for 24 hours at a temperature of 60 ° C and a rotation speed of 500 rpm. hours, the nanoparticle-modified graphene dispersion was obtained. Then the product was separated by suction filtration, and washed three times with acetone and deionized water respectively. Then add 2.0g perfluorooctyltriethoxysilane to the product for hydrophobic modification, react at 80°C for 24 hours, and dry the product obtained after the reaction at 60°C for 12 hours to obtain modified hydrophobic nanoparticles Graphene oxide.

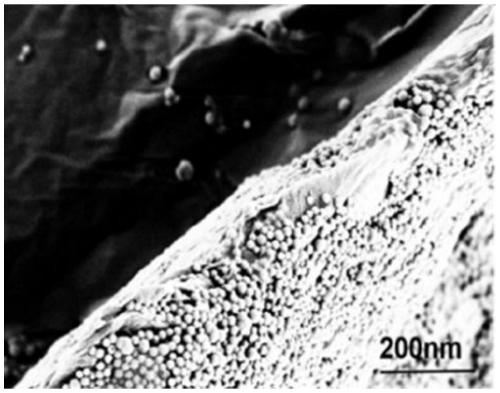

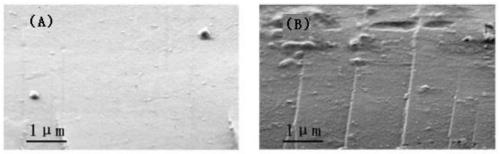

[0053] For morphology observation, see figure 1 , hydrophobic silica nanoparticles coated on the surface of sh...

Embodiment 2

[0056] Example 2: 300 mg of graphene oxide powder was weighed and placed in 200 ml of sodium hydroxide aqueous solution, 0.05 g of ammonia water was added, and stirred at room temperature at 200 rpm for 2 hours to obtain a reaction solution. Add 2.0 g of isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate and 1.0 g of trimethylfluorosilane to the reaction solution, and mechanically stir for 5 hours at room temperature at 200 rpm to obtain nano Particle modified graphene dispersion. The product was then isolated by suction filtration and washed 3 times with deionized water. Then, 3.0 g of glycerol tristearate was added to the product for hydrophobic modification, reacted for 72 hours at a temperature of 40-60° C., and the product was freeze-dried for 12 hours to obtain hydrophobic nanoparticle-modified graphene oxide.

[0057] Weigh 100 mg of the prepared hydrophobic nanoparticle-modified graphene oxide, mix it with 100 g of polysiloxane resin, and 20 g of epox...

Embodiment 3

[0059] Example 3, 50 mg of graphene oxide powder was weighed and placed in a mixed solvent composed of 100 ml of water, 50 ml of ethanol, and 30 ml of isopropanol, 0.05 g of dispersant was added, and stirred at 500 rpm for 2 hours. Transfer the uniformly dispersed mixed solution to a 500mL three-necked flask equipped with a mechanical stirrer, a reflux condenser, and a constant pressure dropping funnel, add 1.0 g of triisopropyl aluminate to the mixed solution, and add 3 mg of sodium ethylate as a catalyst. The temperature was 40° C., and the rotation speed was 1000 rpm under the conditions of mechanical stirring for 20 hours to obtain a nanoparticle-modified graphene dispersion. The product was then isolated by suction filtration and washed 3 times with deionized water. Then, 1.0 g of stearic acid was added to the product for hydrophobic modification, and the reaction was carried out at a temperature of 150° C. for 12 hours. The product was suction-filtered and freeze-dried f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com