A slow-release zeolite molecular sieve integrated protective agent and its preparation method and application

A zeolite molecular sieve, slow-release technology, applied in the addition of fire retardants, anti-biological reagents, inorganic compounds and other directions, can solve the problems of inability to achieve multi-functional integration of deacidification and antibacterial, uncontrollable alkali content, etc. Poisonous and non-irritating, controllable alkali amount and alkali strength, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

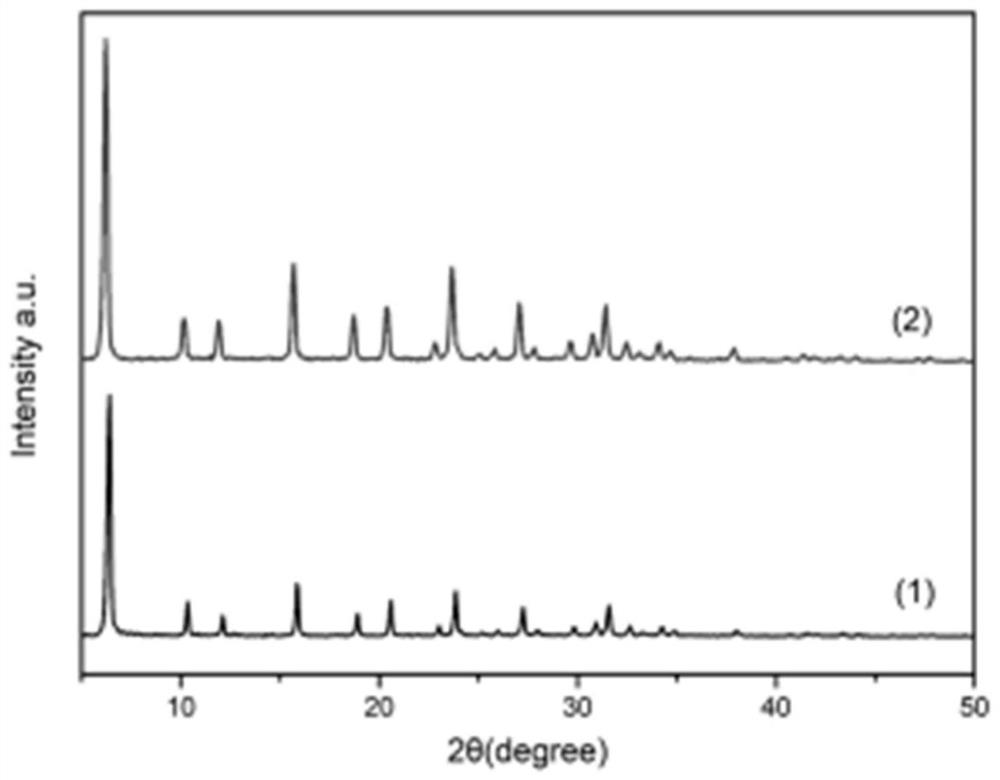

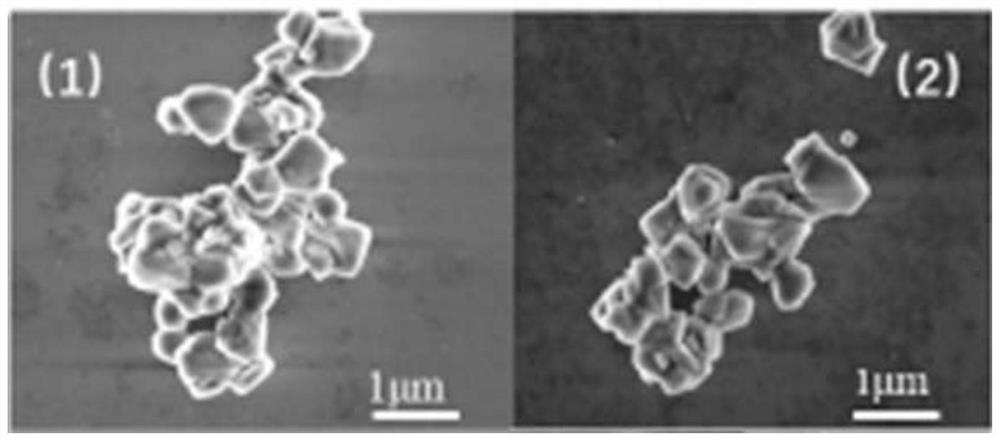

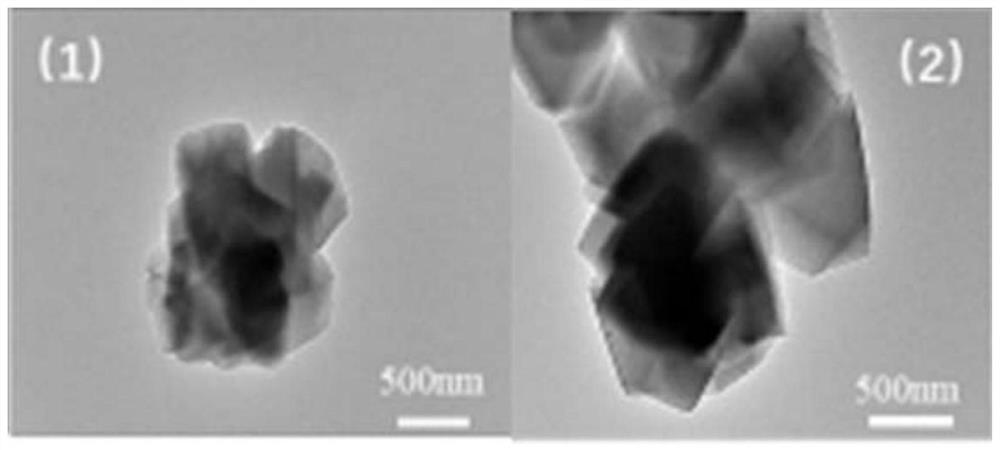

Embodiment 1

[0032] (1) Adopt Y-type zeolite molecular sieve, immerse in the ethanol solution containing the magnesium nitrate of 5wt% and the silver nitrate containing 5wt%, the volume ratio of this solution and zeolite molecular sieve is 25:1, oil bath mode heating, reaction temperature is 90 ℃ , the time is 2h. The solid product was isolated by filtration, washed three times with ethanol, and then calcined at 500° C. for 24 hours under an argon atmosphere. A zeolite molecular sieve loaded with 6wt% magnesium species and 3wt% silver species was obtained, and dispersed in water at a mass ratio of 1wt% to form a slow-release zeolite molecular sieve integrated protective agent. Use the ear washing ball to pre-clean the paper to remove surface impurities, and use the dipping method. The mass ratio of the paper to the integrated protective agent aqueous solution is 0.7:1, the dipping time is 20 minutes, and the temperature is 25°C.

[0033] (2) The paper used is the book paper of a hundred y...

Embodiment 2

[0036](1) Adopt X-type zeolite molecular sieve, immerse the ethanol solution containing the barium sulfate of 1wt% and the silver sulfate containing 2wt%, the volume ratio of this solution and zeolite molecular sieve is 40:1, oil bath mode heating, reaction temperature is 100 ℃ , the time is 5h. The solid product was isolated by filtration, washed three times with ethanol, and then calcined at 400° C. for 48 hours under an argon atmosphere. A zeolite molecular sieve loaded with 0.8wt% of barium ions and 1wt% of silver ions is obtained, which is dispersed in water at a mass ratio of 2wt% to form a slow-release integrated protective agent for zeolite molecular sieves. Use the ear washing ball to pre-clean the paper to remove surface impurities, and use the dipping method. The mass ratio of the paper to the integrated protective agent aqueous solution is 0.01:1, the dipping time is 20 minutes, and the temperature is 20°C.

[0037] (2) The paper used is the book paper of a hundre...

Embodiment 3

[0040] (1) Adopt Y type zeolite molecular sieve, immerse the ethanol solution containing the calcium bicarbonate of 5wt% and the silver nitrate containing 5wt%, the volume ratio of this solution and zeolite molecular sieve is 10:1, oil bath mode heating, reaction temperature is 45 ℃, the time is 15h. The solid product was isolated by filtration, washed three times with ethanol, and then calcined at 650° C. for 36 hours under an argon atmosphere. A zeolite molecular sieve loaded with 1wt% of calcium ions and 2.8wt% of silver ions is obtained and dispersed in water at a mass ratio of 2wt% to form a slow-release zeolite molecular sieve integrated protective agent. Use the ear washing ball to pre-clean the paper to remove surface impurities, and use the dipping method. The mass ratio of the paper to the integrated protective agent aqueous solution is 0.5:1, the dipping time is 20 minutes, and the temperature is 25°C.

[0041] (2) The paper used is handmade bamboo paper with an or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com