Copper-aluminum composite substrate and pressure diffusion welding method and application thereof

A copper-aluminum composite, diffusion welding technology, applied in chemical instruments and methods, lamination, conductive materials, etc., can solve the problems of poor mechanical and electrical properties of metal compounds, difficult alloy processing, etc., to avoid electrochemical corrosion, improve The effect of service life and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

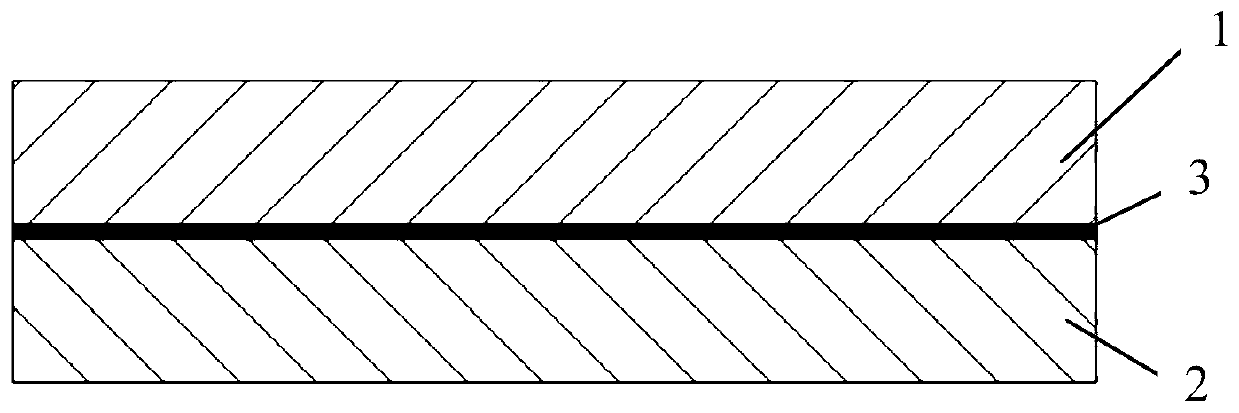

[0057] In this embodiment, pressure diffusion welding is used to provide a copper-aluminum composite substrate, the copper-aluminum composite substrate includes a copper substrate and an aluminum layer; the aluminum layer is arranged on at least one of the copper substrates On the surface, between the copper base and the aluminum layer is a copper-aluminum mixture layer in which copper-aluminum atoms interpenetrate or combine copper-aluminum atoms.

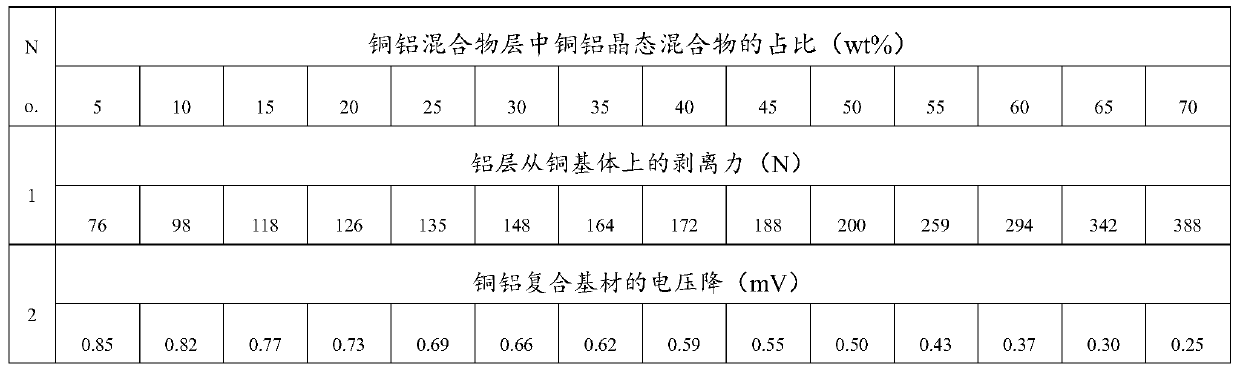

[0058] In this example, in order to demonstrate the effect of the proportion of the copper-aluminum crystalline mixture in the copper-aluminum mixture layer on the performance of the copper-aluminum composite substrate, different copper-aluminum mixtures were produced using the same thickness and material of the copper substrate and the aluminum layer The proportion of the copper-aluminum crystalline mixture in the layer was sampled, and a series of mechanical and electrical tests were done. The experimental results are shown in Ta...

Embodiment 2

[0067] In this embodiment, pressure diffusion welding is used to provide a copper-aluminum composite substrate, the copper-aluminum composite substrate includes a copper substrate and an aluminum layer; the aluminum layer is arranged on at least one of the copper substrates On the surface, between the copper base and the aluminum layer is a copper-aluminum mixture layer in which copper-aluminum atoms interpenetrate or combine copper-aluminum atoms.

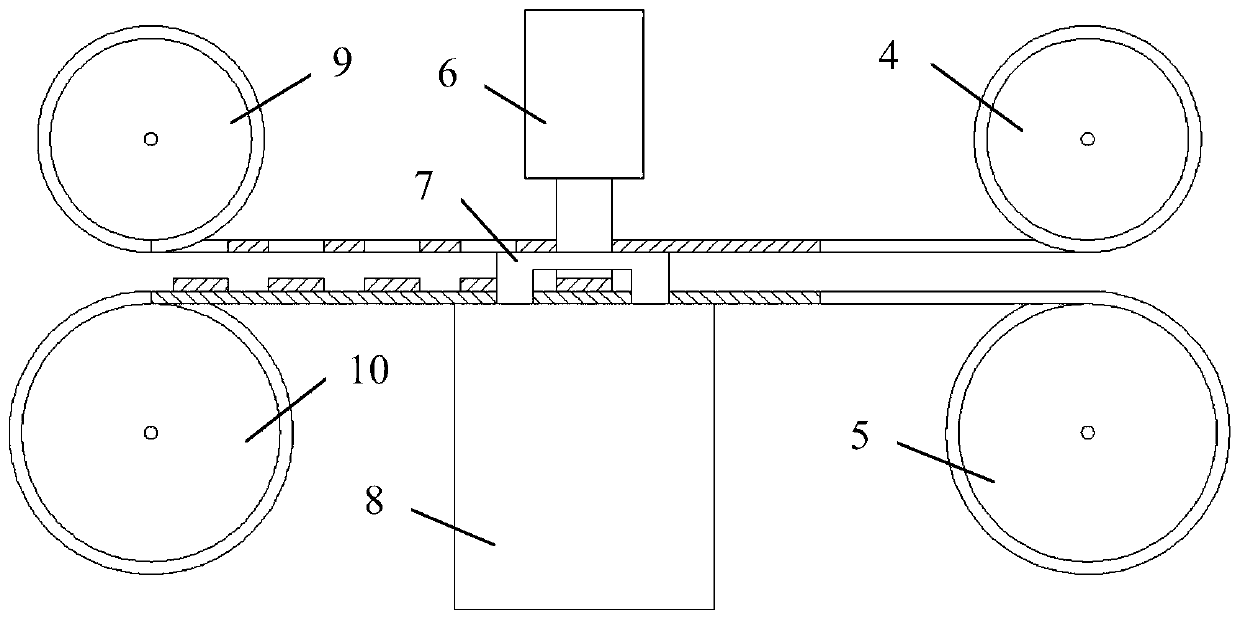

[0068] The pressure diffusion welding processing method of the copper-aluminum composite substrate includes:

[0069] Pretreatment step: after cleaning the copper substrate and the aluminum layer, preheat the copper substrate raw material and / or the copper substrate raw material to 500° C. with high-frequency electromagnetic waves;

[0070] Fixing step: placing the copper matrix raw material and the aluminum layer raw material in a punching machine;

[0071] Stamping step: use a punching machine to stamp the aluminum layer and th...

Embodiment 3

[0083] In this embodiment, pressure diffusion welding is used to provide a copper-aluminum composite substrate, the copper-aluminum composite substrate includes a copper substrate and an aluminum layer; the aluminum layer is arranged on at least one of the copper substrates On the surface, a copper-aluminum mixture layer is formed between the copper substrate and the aluminum layer in which copper-aluminum atoms interpenetrate or combine copper-aluminum atoms, and the copper-aluminum mixture layer contains at least 50wt% copper-aluminum crystalline mixture.

[0084] The pressure diffusion welding processing method of the copper-aluminum composite substrate includes:

[0085] Pretreatment step: after cleaning the copper substrate and the aluminum layer, preheating the copper substrate raw material and / or the copper substrate raw material with high-frequency electromagnetic waves;

[0086] Fixing step: placing the copper matrix raw material and the aluminum layer raw material in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com