Combined conditioning agent for sludge deep dewatering and mud cake stabilization and application of combined conditioning agent

A deep dehydration and conditioning agent technology, applied in water/sludge/sewage treatment, sludge treatment, water pollutants, etc., can solve the problems of inactivation of parasite eggs and pathogens, etc., to achieve simple process and good effect , the effect of easily controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

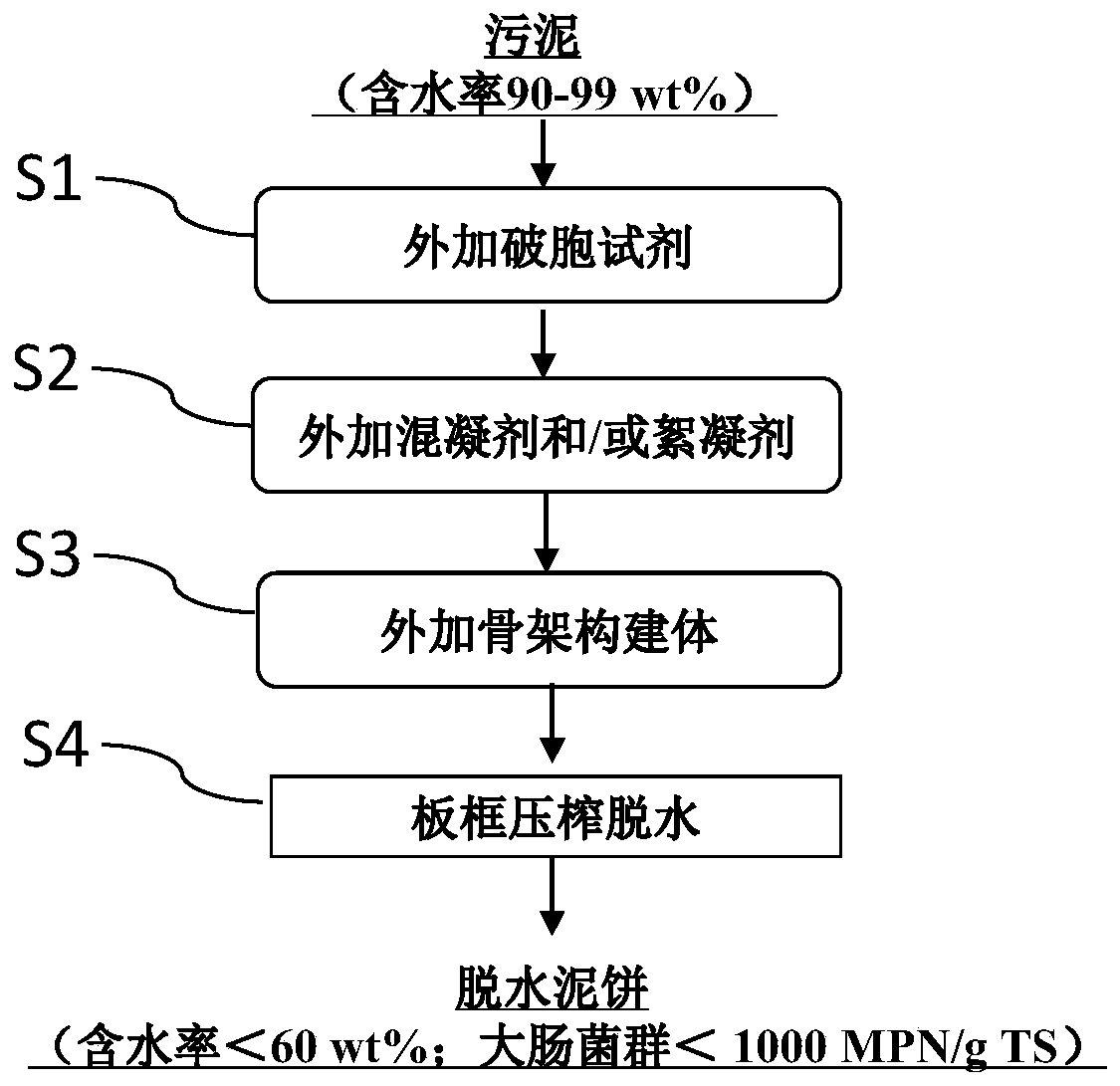

[0052] A method for deep dewatering of sludge, the process steps are as follows:

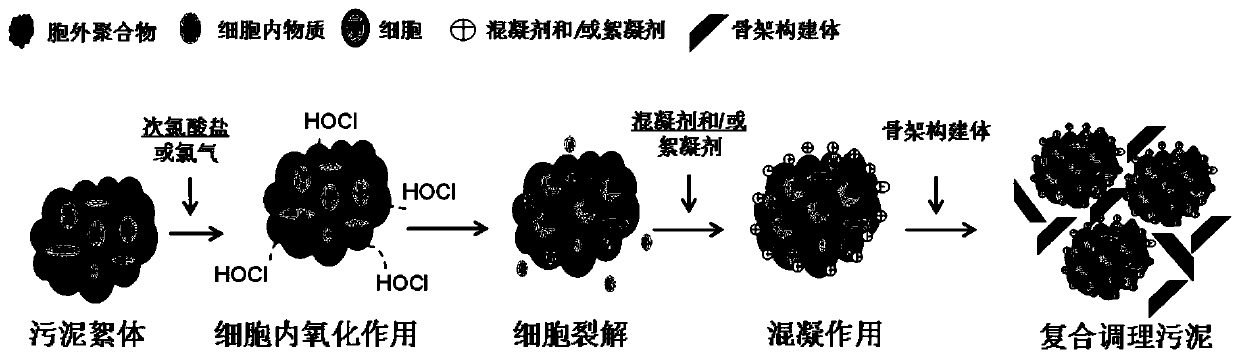

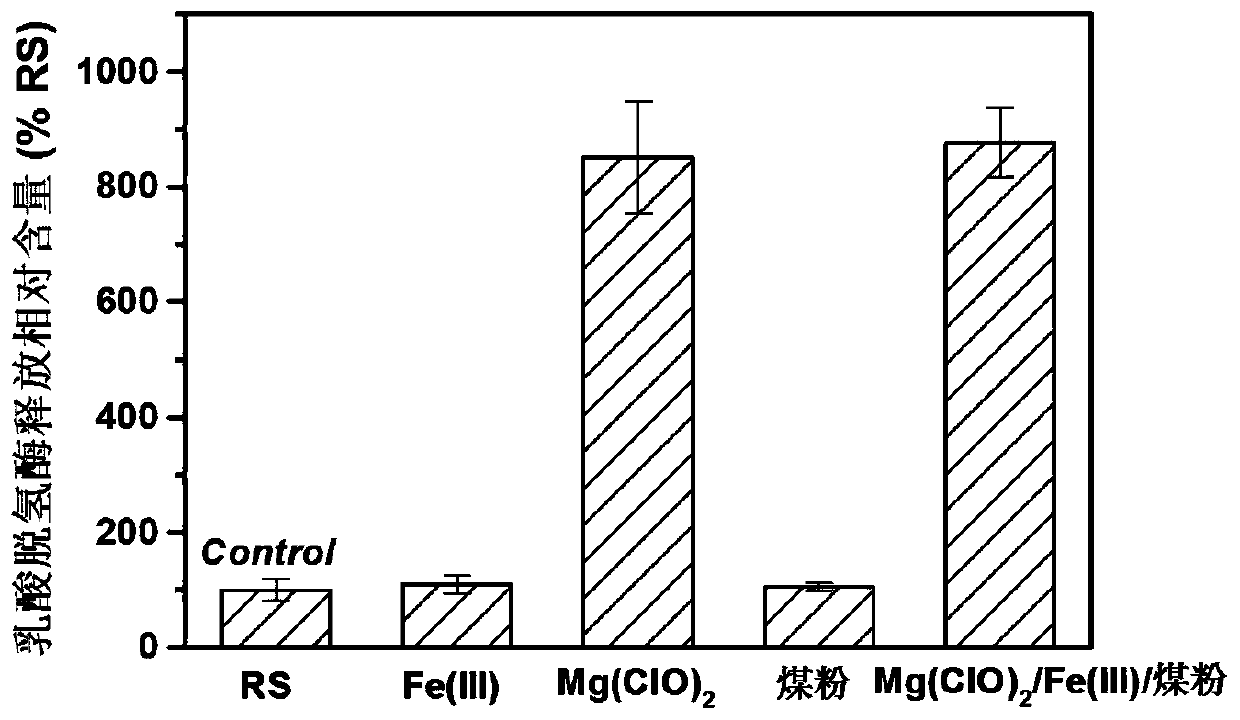

[0053] S1: Taking the remaining sludge with an organic content of 55.9wt% and a water content of 98.4wt% as a starting point, add magnesium hypochlorite with a sludge organic content of 26.5wt% to the sludge, and stir for 5 minutes;

[0054] S2: Add the iron trichloride of 45.2wt% of sludge organic matter content in the sludge after step S1 treatment, stir 10 minutes and finish sludge conditioning;

[0055] S3: Add the fly ash of 10wt% of sludge organic matter content in the sludge after step S2 treatment, stir 10 minutes and finish sludge conditioning;

[0056] S4: The sludge conditioned in step S3 is dehydrated by plate and frame.

[0057] After testing, the specific resistance of sludge filtration is 1.88×10 13 m / kg down to 0.12×10 13 m / kg, the capillary water absorption time of the sludge decreased from 172.7s of the original sludge to 29.8s, and the moisture content of the conditioned sl...

Embodiment 2

[0059] A method for deep dewatering of sludge, the process steps are as follows:

[0060] S1: With organic matter content being 45.2wt%, water content is 97.1wt% remaining sludge as starting point, in sludge, add the chlorine gas of sludge organic matter content 10.2wt%, stir 10 minutes;

[0061] S2: Add ferric chloride of 15wt% of sludge organic content to the sludge treated in step S1, and stir for 10 minutes; add polyacrylamide of 0.02wt% of sludge organic content to the sludge, stir 10 minutes;

[0062] S3: Add the 50wt% magnesite of sludge organic matter content in the sludge after step S2 treatment, stir 10 minutes and finish sludge conditioning;

[0063] S4: The sludge conditioned in step S3 is dehydrated by plate and frame.

[0064] After testing, the specific resistance of sludge filtration is 1.45×10 13 m / kg down to 0.07×10 13 m / kg, the capillary water absorption time of the sludge decreased from 156.2s of the original sludge to 25.1s, and the water content of th...

Embodiment 3

[0066] S1: With organic matter content being 49.5wt%, moisture content is 96.5wt% remaining sludge as a starting point, adding sodium hypochlorite with sludge organic matter content 20.1wt% to the sludge, stirring for 3 minutes;

[0067] S2: Add the aluminum chloride of 20wt% of sludge organic matter content in the sludge after step S1 treatment, stir 5 minutes;

[0068]S3: Add coal powder with an organic content of 180wt% to the sludge treated in step S2, and stir for 10 minutes to complete sludge conditioning;

[0069] S4: The sludge conditioned in step S3 is dehydrated by plate and frame.

[0070] After testing, the specific resistance of sludge filtration is 2.41×10 13 m / kg down to 0.09×10 13 m / kg, the capillary water absorption time of the sludge decreased from 268.2s of the original sludge to 30.1s, and the water content of the conditioned sludge was 56.5wt% after the plate and frame dehydration. The number of coliform bacteria in the mud cake decreased from 13566MPN / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com