A kind of polyamic acid and its preparation method, polyimide heat conduction film and its preparation method

A polyimide and polyamic acid technology, applied in the field of nanocomposite materials, can solve the problems of few reactive sites and limited increase in thermal conductivity, so as to facilitate large-scale production, improve effects, and enhance interaction force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

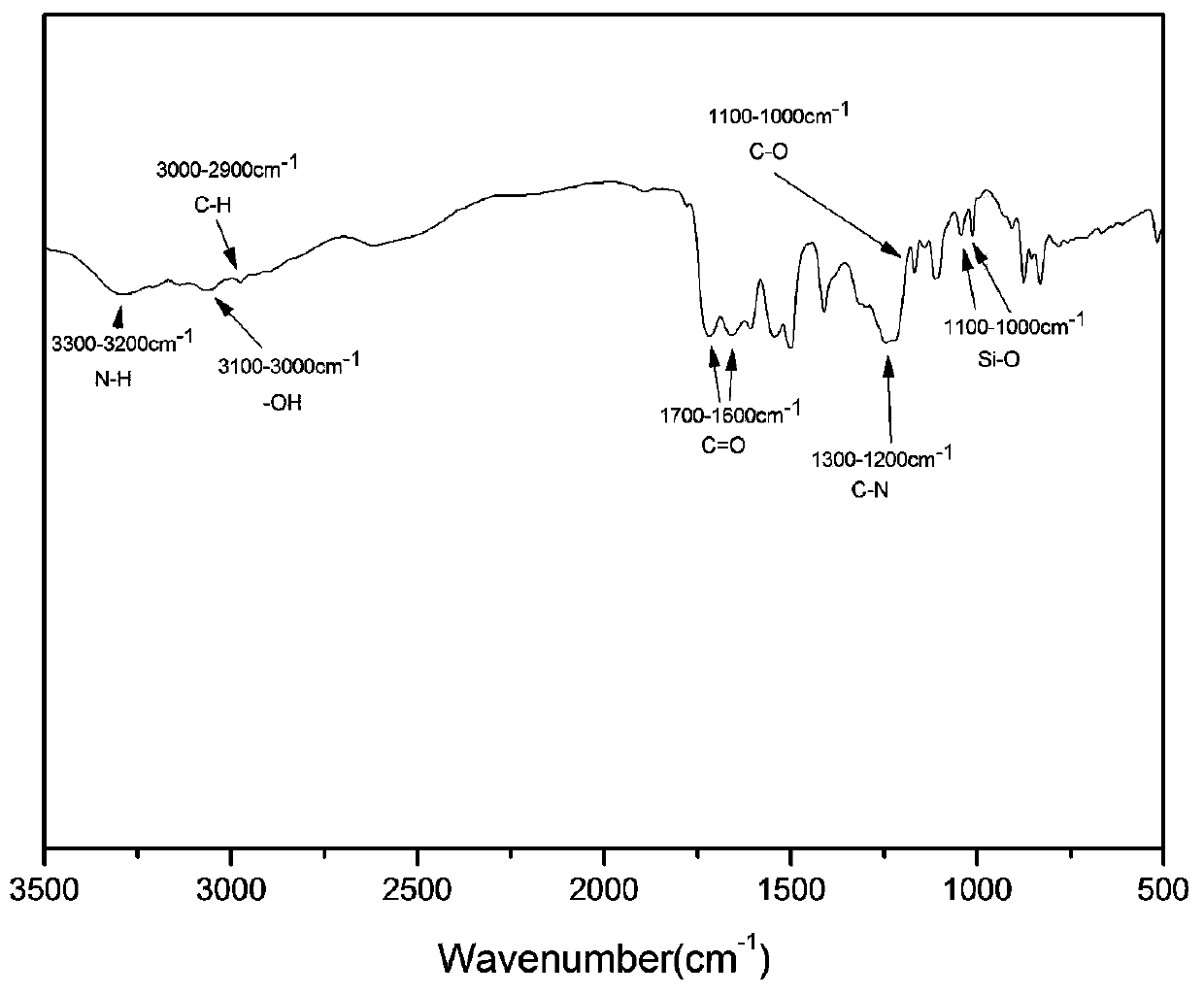

[0054] The present invention provides the preparation method of polyamic acid described in above-mentioned technical scheme, comprises the following steps:

[0055] Mix diamine, dianhydride and polar organic solvent for copolymerization to obtain polyamic acid;

[0056] The diamine includes diamine A and diamine B, and the diamine A includes 3,3'-diaminodiphenyl ether, 3,4'-diaminodiphenyl ether, 4,4'-diaminodiphenyl ether ether, 2,3-diaminotoluene, 4,4'-diaminodiphenylsulfone, 4,4'-diaminobiphenyl or 1,1-bis(4-aminophenyl)cyclohexane, 4,4 One or more of '-diaminodiphenylmethane and 4,4'-diaminobenzophenone; the diamine B includes 4-dimethyl (ethoxy) silylbenzene-1,2 -diamine, 5-(triethoxysilyl)-1,3-phenylenediamine, 4-(4-aminophenoxy)-3-trimethoxysilyl)aniline, 3,5-diamino -N-(4-trimethoxysilyl)phenyl)benzamide, 3,5-diamino-N-(4-dimethoxy(methyl)silyl)phenyl)benzamide and 3 , one or more of 5-diamino-N-(3-(4-(triethoxysilyl)phenyl)propyl)benzamide;

[0057] The dianhydrid...

Embodiment 1

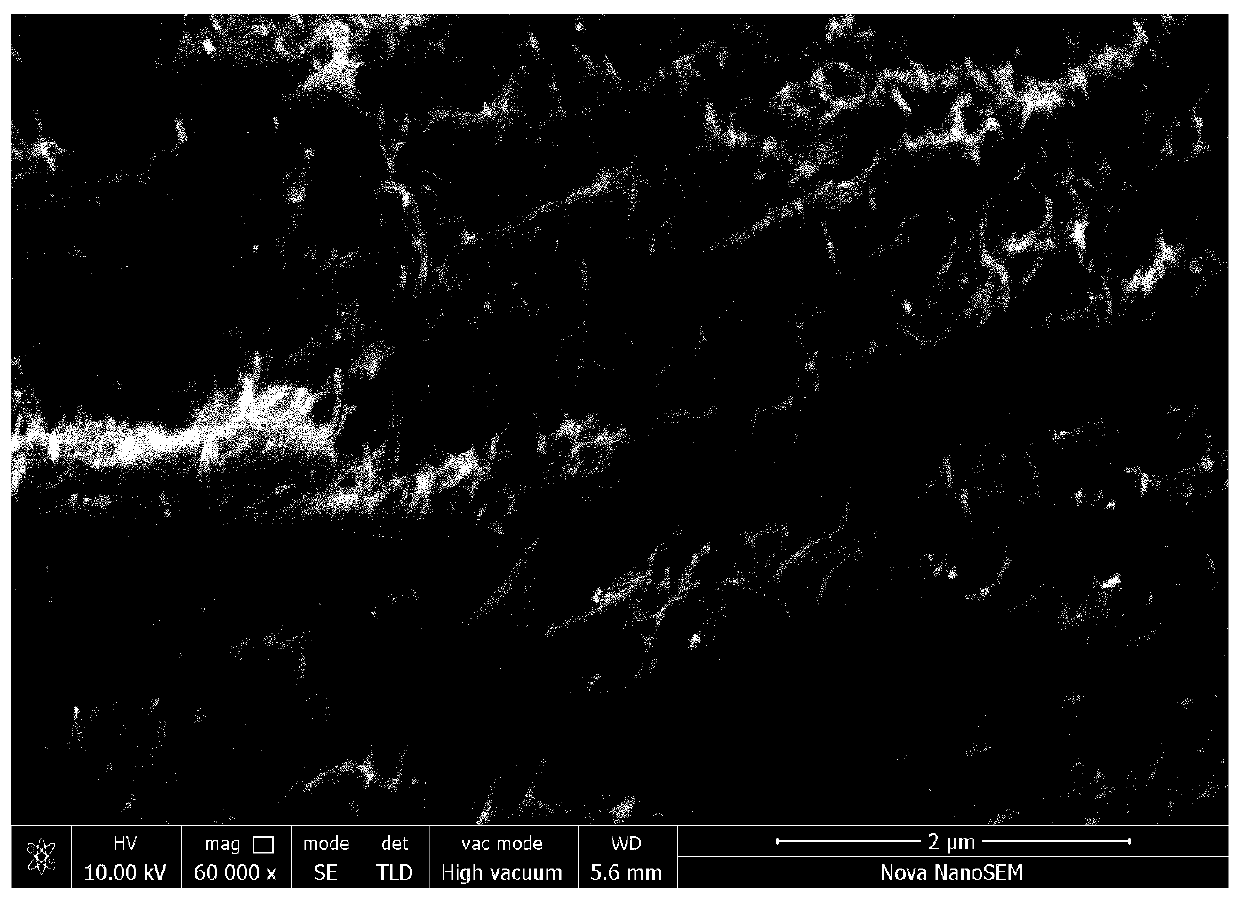

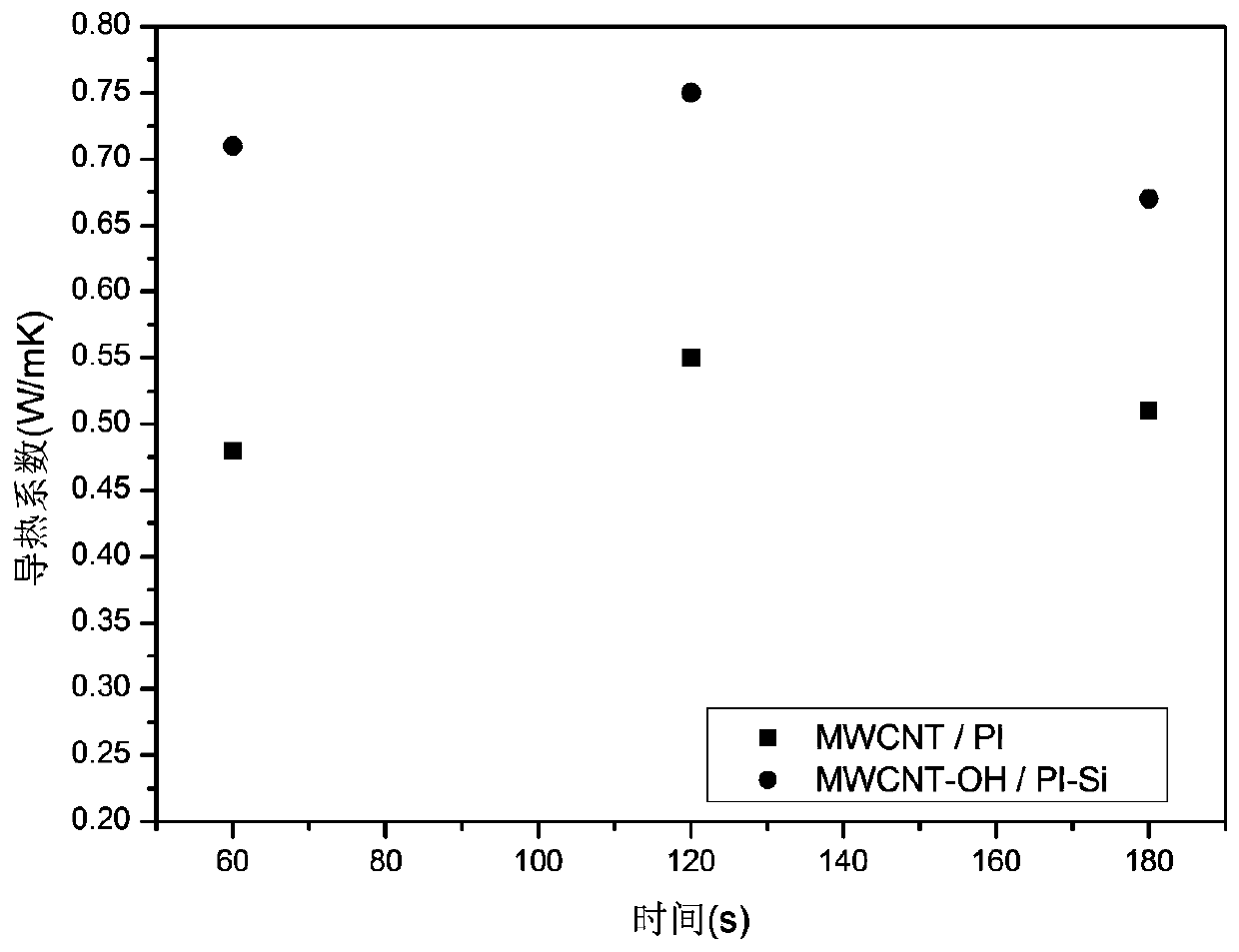

[0089] Weigh 0.1500 g of hydroxylated single-walled carbon nanotubes (20 μm in length and 1 nm in diameter) and place them in a three-necked flask filled with 92.08 mL of N,N-dimethylacetamide (DMAc) solution, and heat them at 40 kHz, 250 W Ultrasonic treatment for 2 hours under the condition of ultrasonic dispersion, the three-necked flask was connected to the inlet of nitrogen gas, and the tetrafluoro stirring blade was added to the reaction kettle successively. g (3.59mmol) 4-dimethyl (ethoxy) silylbenzene-1,2-diamine, start stirring, and stir fully at a speed of 2000r / min until the added diamine is completely dissolved; then add 10.5596g (35.89mmol) 3,3',4,4'-biphenyltetracarboxylic dianhydride, stirring constantly, and controlling the temperature at 20°C for copolymerization for 12h (during the copolymerization, when the solution viscosity increases significantly When the rod is climbed, the stirring rate is appropriately reduced until the phenomenon of climbing the rod i...

Embodiment 2

[0091] Weigh 0.7500g of hydroxylated double-walled carbon nanotubes (10 μm in length and 2nm in diameter) and place them in a three-necked flask containing 86.86mL of N-methylpyrrolidone (NMP) solution, and disperse them under ultrasonic dispersion conditions of 40kHz and 250W. Under the ultrasonic treatment for 2h, the three-neck flask was connected to the inlet of nitrogen gas, and the tetrafluoro stirring blade was added to the reaction kettle successively. ) 5-(triethoxysilyl)-1,3-phenylenediamine, start stirring, fully stir at a speed of 2000r / min until the added diamine is completely dissolved; then add 9.6952g (31.25mmol) at one time 3,3',4,4'-Diphenyl ether tetra-acid dianhydride, stirring continuously, and controlling the temperature at 20°C for copolymerization for 12h, (during the copolymerization, when the solution viscosity increases significantly to the Appropriately reduce the stirring rate until the rod-climbing phenomenon is not obvious, continue to maintain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com