Preparation method of composite electrode, composite electrode and lithium ion battery

A composite electrode and discharge plasma technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve problems such as interface instability and large interface impedance, and achieve the effect of shortening the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

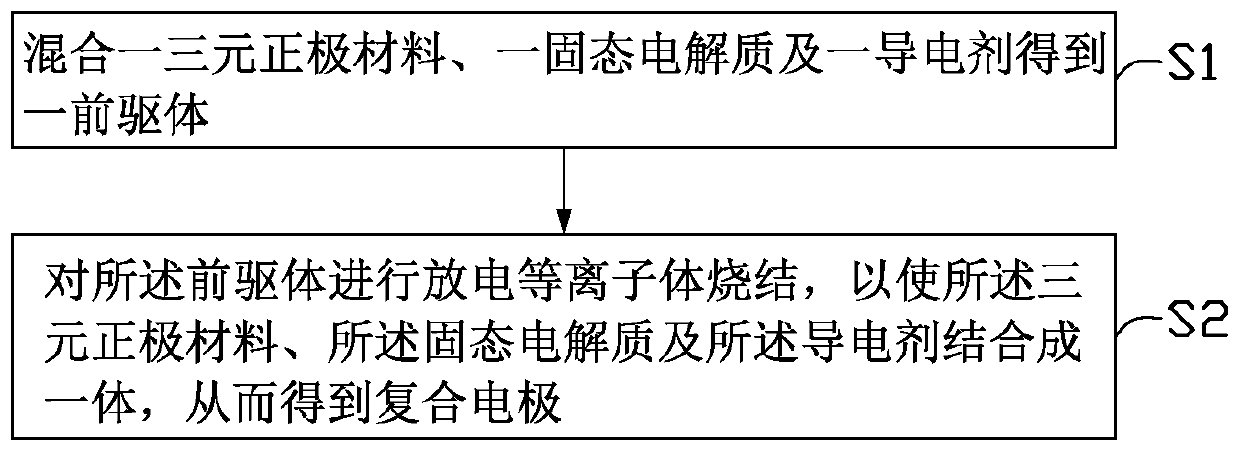

[0036] see figure 1 , a method for preparing a composite electrode provided in an embodiment of the present invention, comprising the following steps:

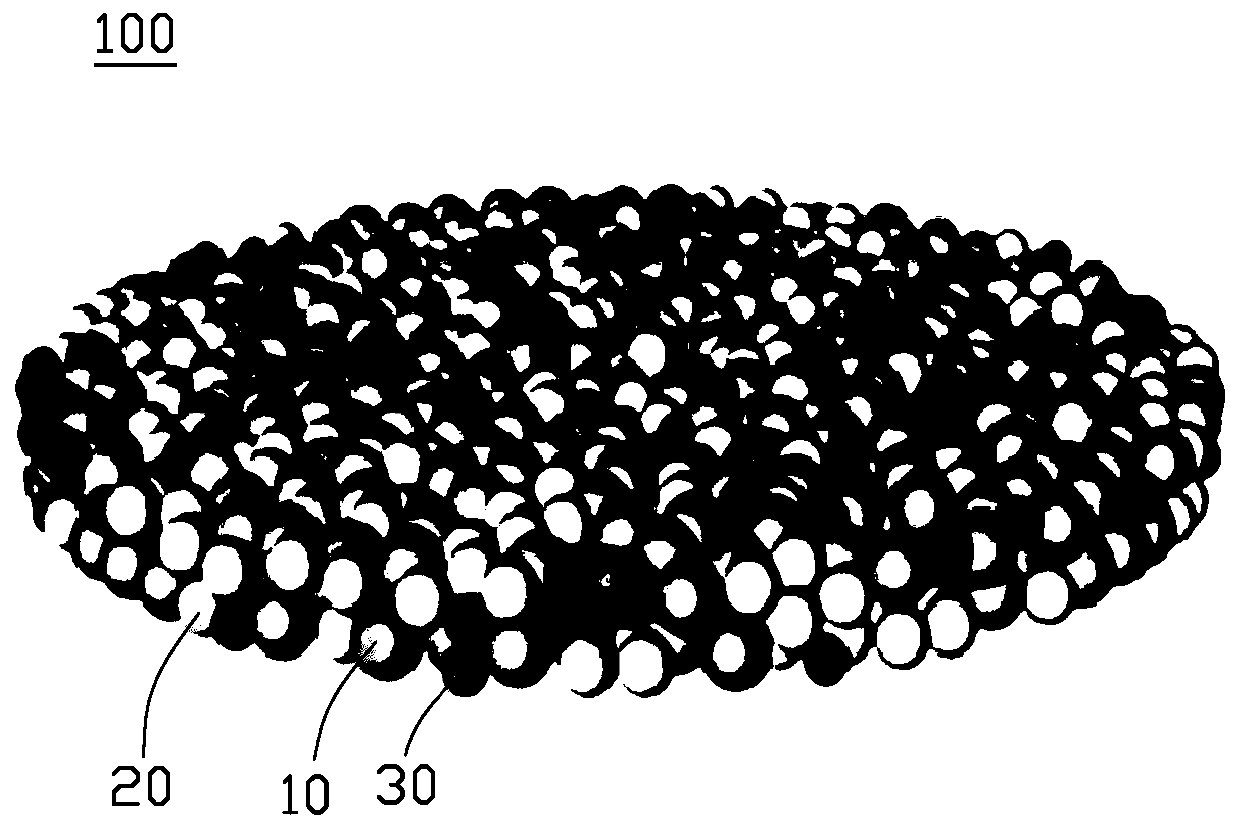

[0037] Step S1: mixing a ternary positive electrode material 10, a solid electrolyte 20 and a conductive agent 30 to obtain a precursor;

[0038] Step S2: performing discharge plasma sintering on the precursor, so that the ternary positive electrode material 10, the solid electrolyte 20 and the conductive agent 30 are combined into one body, so as to obtain the composite electrode 100.

[0039] In step S1, the ternary positive electrode material 10 is at least one of nickel-cobalt-manganese ternary material (NCM) and nickel-cobalt-aluminum ternary material (NCA) commonly used in lithium-ion battery positive electrode materials, such as LiNi 0.8 co 0.15 al 0.05 o 2 .

[0040] The solid electrolyte 20 is at least one of the commonly used solid electrolytes 20 for lithium ion batteries, such as garnet-type solid electrolyte ...

Embodiment

[0064] Take LiNi 0.8 co 0.15 al 0.05 o 2 (NCA) as a ternary cathode material 10, Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 (LLZTO) as solid electrolyte 20, indium tin oxide (ITO) as conductive agent 30, LiNi 0.8 co 0.15 al 0.05 o 2 , Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 Mixed with indium tin oxide in a mass ratio of 6:3:1, and then placed in a ball mill jar for ball milling for 30 minutes to obtain a uniformly mixed precursor; the precursor was cold-pressed, and then mixed with Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 The powder is cold-pressed at a mass ratio of 1:1, and a precursor having a double-layer structure of the precursor and the solid electrolyte 20 is prepared first.

[0065] Then the precursor is subjected to spark plasma sintering treatment. Place the precursor of the double-layer structure in the discharge plasma sintering equipment, raise the temperature to 500°C at a heating rate of 100°C / min, and then raise the temperature at a heating rate of 50°C / min, and control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com