Preparation process and device for titanium alloy cast three-dimensional printing ceramic mold shell

A technology of three-dimensional printing and preparation technology, which is applied in the field of titanium alloy casting, can solve problems such as explosion, and achieve the effects of good thermal strength, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

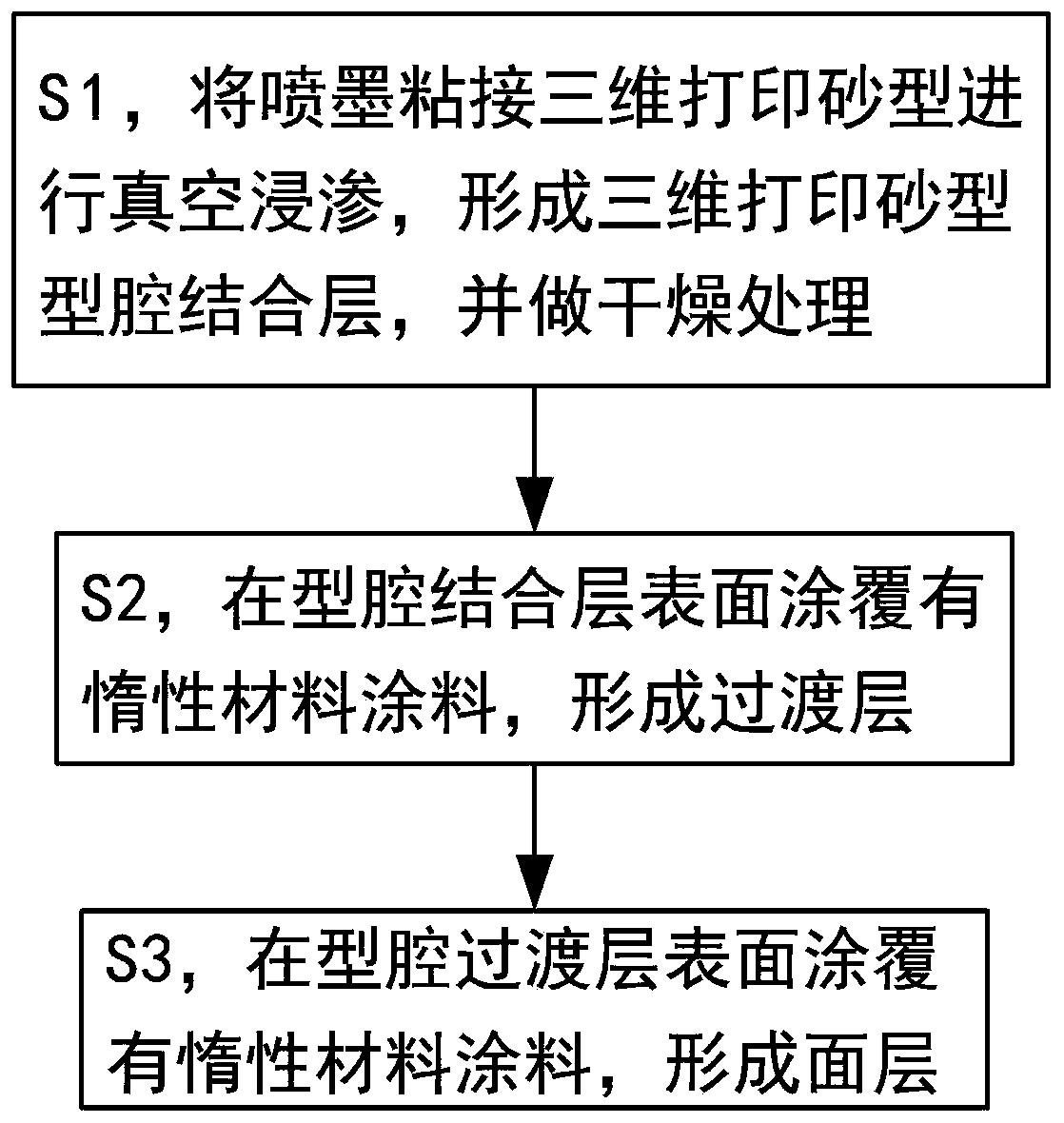

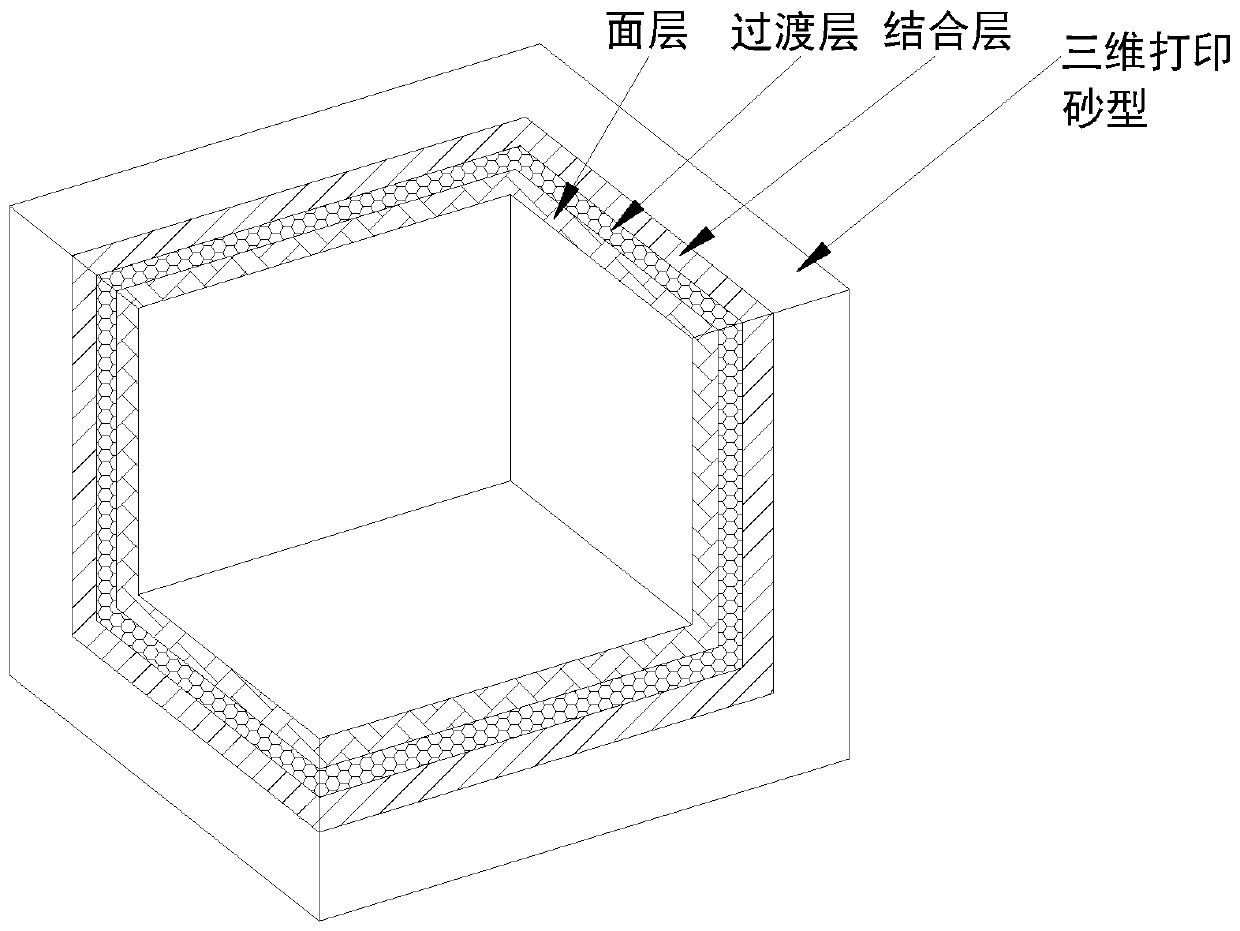

[0027] Embodiment 1 of the present invention: as figure 1 and image 3 As shown, a preparation process for a three-dimensionally printed ceramic shell for titanium alloy casting comprises the following steps:

[0028] S1, vacuum impregnate the inkjet bonded 3D printing sand mold to form a 3D printing sand mold cavity bonding layer, and perform drying treatment;

[0029] S2, the surface of the cavity bonding layer is coated with an inert material coating to form a transition layer;

[0030] S3, the surface of the cavity transition layer is coated with an inert material paint to form a surface layer.

Embodiment 2

[0031] Embodiment 2: as figure 1 and image 3 As shown, a preparation process for a three-dimensionally printed ceramic shell for titanium alloy casting comprises the following steps:

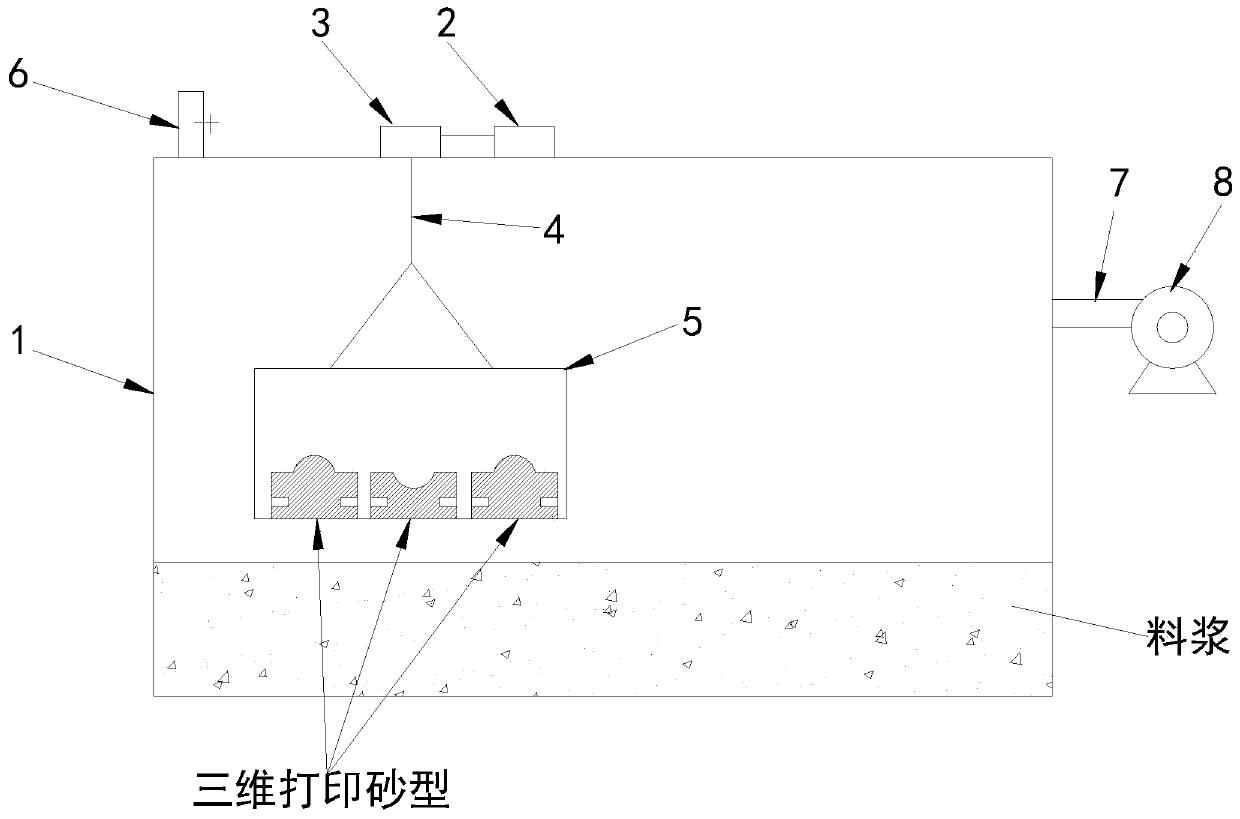

[0032] S1, vacuum impregnate the inkjet bonded 3D printing sand mold to form a 3D printing sand mold cavity bonding layer, and do drying treatment; specifically include the following process: use a vacuum impregnation device to evenly absorb the infiltrating slurry on the surface of the 3D printing sand mold , at a relative humidity of 40%-70% and a temperature of 15°C-30°C, naturally harden for 4-6 hours and dry to form a bonding layer. The slurry components are silica sol and mullite powder with a weight ratio of 12-6:1-4, and the viscosity of the slurry is 2 seconds to 6 seconds.

[0033] S2, the surface of the cavity bonding layer is coated with an inert material coating to form a transition layer; specifically includes the following process: the weight ratio of 0.5-2:1.5-3.5 yttrium sol ...

Embodiment 3

[0035] Embodiment 3: as figure 1 and image 3 As shown, a preparation process for a three-dimensionally printed ceramic shell for titanium alloy casting comprises the following steps:

[0036]S1, vacuum impregnate the inkjet bonded 3D printing sand mold to form a 3D printing sand mold cavity bonding layer, and do drying treatment; specifically include the following process: use a vacuum impregnation device to evenly absorb the infiltrating slurry on the surface of the 3D printing sand mold , when the relative humidity is 50%-60%, the temperature is 18°C-26°C, the slurry is naturally hardened for 3-5 hours until it is completely dry, and the thickness of the prepared bonding layer is 5-10mm, the performance parameters are better. . The vacuum impregnation device can make the slurry enter the loose 3D printing sand surface more smoothly. Mullite powder is ultra-fine mullite powder below 10 microns, the weight ratio of silica sol and mullite powder is 8:1, the viscosity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com