A kind of pvc edge banding and preparation method thereof

A technology of edge banding and body, which is applied in the direction of film/sheet release coating, heat-activated film/sheet, film/sheet adhesive, etc., which can solve the problem that the use of edge banding is not well considered. and other issues, to achieve the effect of providing overall stability, good adhesion, and good aging resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

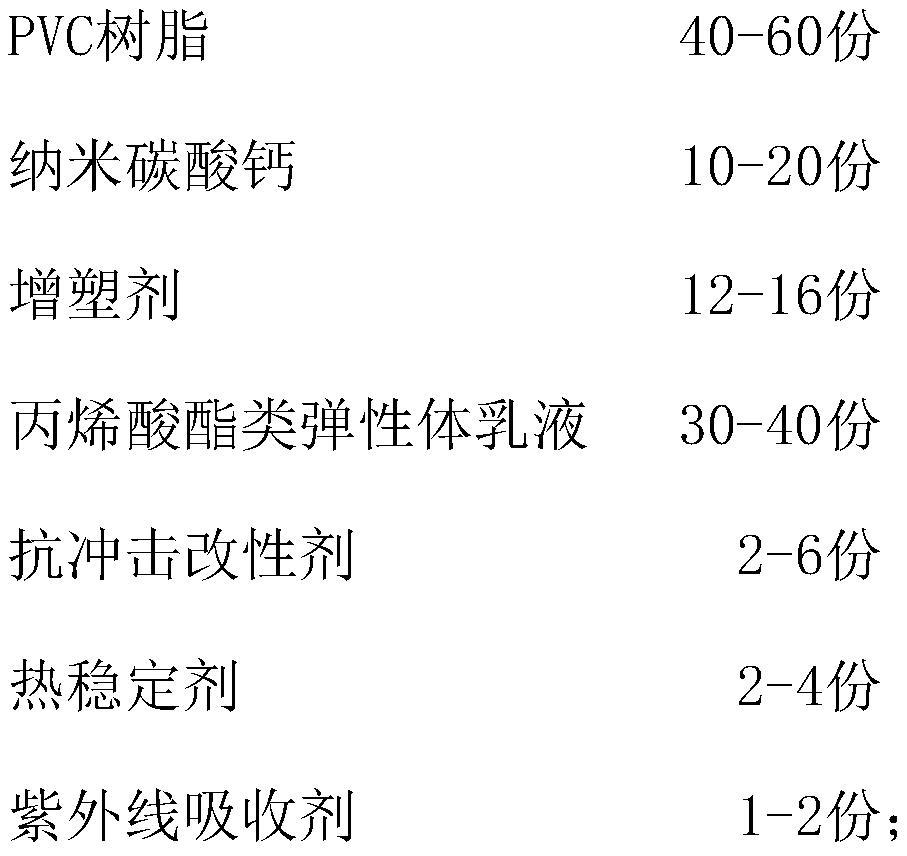

[0055] A PVC edge banding strip, comprising an edge banding strip body, the back of the edge banding strip body is sequentially compounded with a primer layer and a hot melt adhesive layer, and the edge banding strip body is made of the following raw materials in parts by weight:

[0056] PVC resin 50 parts

[0057] Nano calcium carbonate 15 parts

[0058] 14 parts plasticizer

[0059] Acrylic Elastomer Emulsion 35 parts

[0060] Impact modifier 4 parts

[0061]3 parts heat stabilizer

[0062] 1.5 parts of ultraviolet absorber;

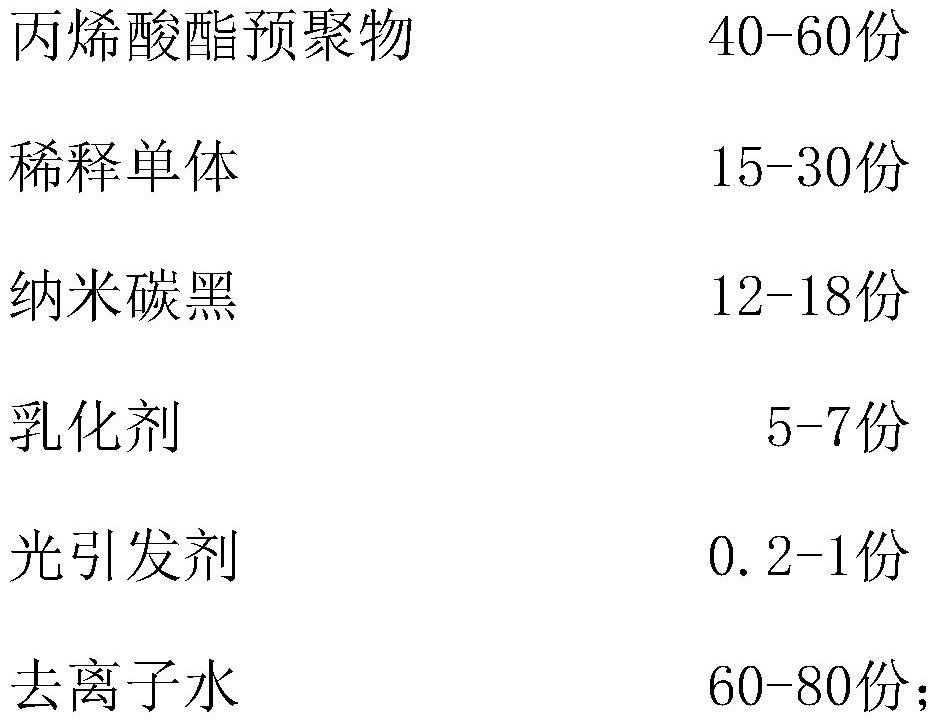

[0063] The primer layer is formed by UV curing of acrylic paint, and the acrylic paint includes the following raw materials in parts by weight:

[0064] Acrylate prepolymer 50 parts

[0065] Dilute monomer 23 parts

[0066] Nano carbon black 15 parts

[0067] Emulsifier 6 parts

[0068] Photoinitiator 0.6 part

[0069] 70 parts of deionized water.

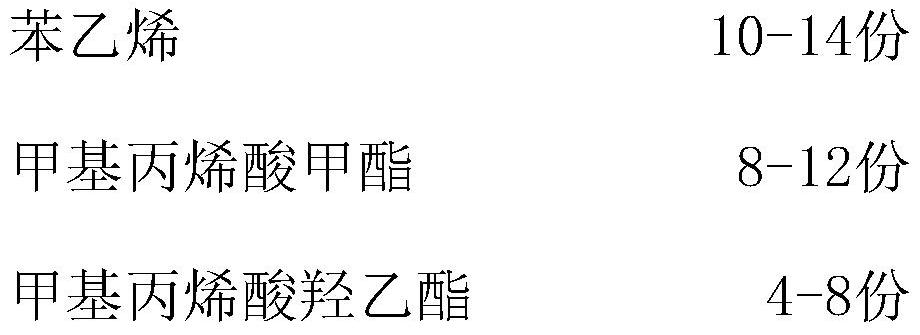

[0070] Wherein, described acrylate elastomer emulsion comprises the raw material of followin...

Embodiment 2

[0099] A PVC edge banding strip, comprising an edge banding strip body, the back of the edge banding strip body is sequentially compounded with a primer layer and a hot melt adhesive layer, and the edge banding strip body is made of the following raw materials in parts by weight:

[0100] PVC resin 40 parts

[0101] Nano calcium carbonate 10 parts

[0102] Plasticizer 12 parts

[0103] Acrylic Elastomer Emulsion 30 parts

[0104] Impact modifier 2 parts

[0105] 2 parts heat stabilizer

[0106] 1 part UV absorber;

[0107] The primer layer is formed by UV curing of acrylic paint, and the acrylic paint includes the following raw materials in parts by weight:

[0108] Acrylate prepolymer 40 parts

[0109] Dilute monomer 15 parts

[0110] Nano carbon black 12 parts

[0111] Emulsifier 5 parts

[0112] Photoinitiator 0.2 parts

[0113] 60 parts of deionized water.

[0114] Wherein, described acrylate elastomer emulsion comprises the raw material of following parts by we...

Embodiment 3

[0143] A PVC edge banding strip, comprising an edge banding strip body, the back of the edge banding strip body is sequentially compounded with a primer layer and a hot melt adhesive layer, and the edge banding strip body is made of the following raw materials in parts by weight:

[0144] 60 parts of PVC resin

[0145] Nano calcium carbonate 20 parts

[0146] Plasticizer 16 parts

[0147] Acrylic elastomer emulsion 40 parts

[0148] Impact modifier 6 parts

[0149] Heat stabilizer 4 parts

[0150] 2 parts of UV absorber;

[0151] The primer layer is formed by UV curing of acrylic paint, and the acrylic paint includes the following raw materials in parts by weight:

[0152] Acrylate prepolymer 60 parts

[0153] Dilute monomer 30 parts

[0154] Nano carbon black 18 parts

[0155] Emulsifier 7 parts

[0156] Photoinitiator 1 part

[0157] 80 parts of deionized water.

[0158] Wherein, described acrylate elastomer emulsion comprises the raw material of following parts by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com