Silver nanothread/silk fibroin composite fiber and preparation method thereof

A technology of silk fibroin and silver nanowires, applied in the field of fiber materials, can solve the problems of no obvious improvement in electrical conductivity, no improvement in flexibility, complicated operation process, etc., to solve the problems of low reduction efficiency, improved mechanical properties, enhanced Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A preparation method of silver nano wire / silk fibroin composite fiber, comprising the following steps:

[0056] Preparation of S1 silk fibroin membrane:

[0057] S11 Boil silkworm cocoons in 0.5wt% Na2CO3 aqueous solution for 30 minutes for degumming, and thoroughly wash with deionized water for 3 times, each time for 20 minutes;

[0058] S12 After thoroughly drying overnight in the air, dissolve the degummed silk fibroin in 9.0M lithium bromide aqueous solution at 60°C for 4h;

[0059] S13 Dialyze the solution described in S12 with deionized water for 3 days under the cellulose membrane of the dialysis tubing (molecular weight cut-off: 14000);

[0060] S14 Centrifuge the obtained silk fibroin aqueous solution twice at 9000 rpm for 20 min, and then put it into a petri dish to evaporate to obtain a regenerated silk fibroin film.

[0061] S2 Synthesis of AgNWs using a modified polyol method:

[0062] S21 Dissolve 35g PVP and 80mg ZnCl 2 in 300mL EG, stir and dissolve a...

Embodiment 2-4

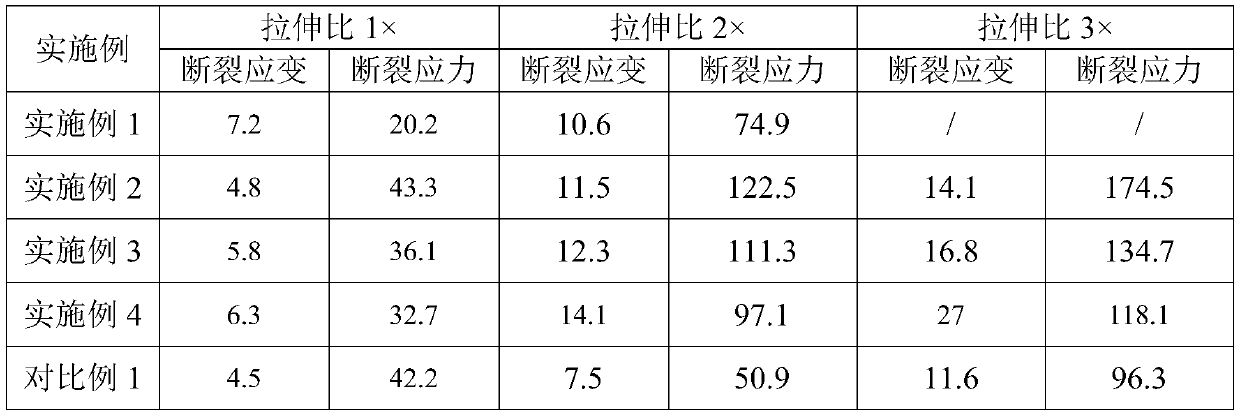

[0086] Embodiment 2-4 provides the preparation method of nano-silver wire-silk fibroin composite fiber, compared with embodiment 1, the difference is that the mass fraction of silver nano-wire is changed, except for the above-mentioned difference, other operations are the same, No more details here; the specific parameters are shown in Table 1.

[0087] Table 1

[0088] Example AgNW(wt%) Example 1 25.1 Example 2 5.9 Example 3 12.1 Example 4 18.1

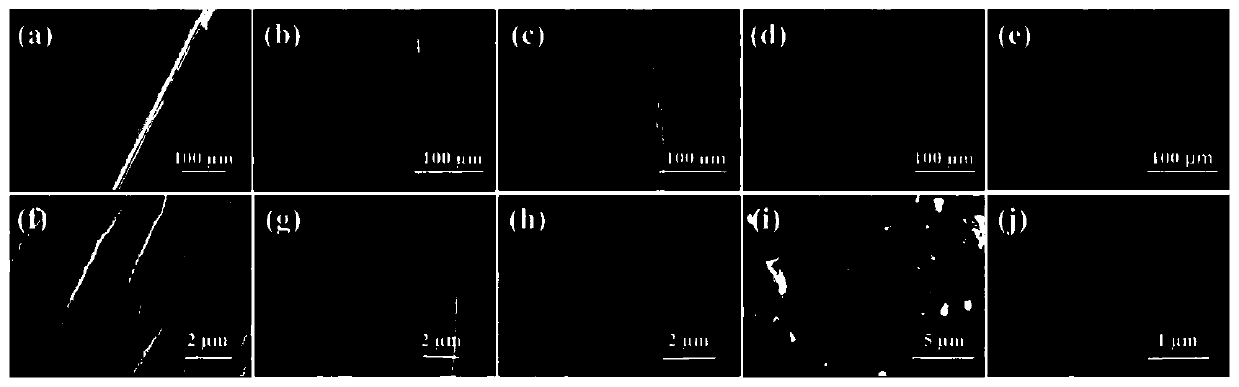

[0089] Embodiment 1-4 of the present invention and the silk fibroin fiber SEM figure that comparative example 1 prepares carry out comparative analysis, as figure 1 shown. The results showed that the pure regenerated silk fibroin fibers were colorless, while the AgNW / silk fibroin composite fibers were dark and monofilamentous. With the increase of AgNW concentration, the color of the composite fiber becomes darker gradually. The surface morphologies of pure regenerated silk fibroin fibers a...

experiment example 1

[0103] Experimental example 1 Folding test of composite fiber

[0104]Foldability of composite fibers with 18.0wt% AgNW during 180° inner and outer folding. Such as figure 2 As shown in (a), a test device was prepared by connecting and mounting the composite fiber and fiber LED lamp on a PET substrate using double-sided adhesive tape and tinfoil. When electricity passes through the device, the LED glows red. When the substrate is folded inwards, the LED lights are still bright and the brightness is not reduced. When turned on, the LED light remains steady. In the folding test, the fibers exhibited high flexibility and electrical conductivity due to the synergistic effect of the silk fibroin fiber matrix and the AgNW conductive filler. Fold-out tests were also performed, as figure 2 (b) shown. When the PET substrate is folded outward by 180°, the LED light also glows red, but the fiber is not damaged, and the LED light is still stable.

[0105] In summary, the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com