Polyester textile dyeing method

A dyeing method and textile technology, applied in the field of polyester textile dyeing, can solve the problems of poor biodegradability, environmental pollution, heavy odor, etc., and achieve the effects of uniform dyeing, energy saving and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for dyeing polyester textiles, comprising the steps of:

[0035] S1. Preparation of slurry: at a stirring rate of 600r / min, slowly add 20g of polyvinyl alcohol with a degree of polymerization of 1000 and 1g of sodium lauryl sulfate into 100mL of deionized water, and stir at 70°C for 6h to make the polyvinyl alcohol Dissolved to obtain a slurry for subsequent use;

[0036] S2. Pretreatment of polyester textiles: boil the polyester staple fibers to be dyed in hot water at 70°C for 40 minutes for pretreatment;

[0037] S3. Dyeing slurry preparation: sequentially add 1g of disperse dye and 0.3g of penetrant JFC to the slurry prepared in step S1, heat up to 80°C, stir at 600r / min for 4h to make it evenly mixed, then add acetic acid to adjust the pH of the solution to 5, get dyeing paste;

[0038] S4. Dyeing: heat the dyeing slurry prepared in step S3 to 90°C, immerse the polyester textile pretreated in step S2 in the dyeing slurry for 25 minutes, and pass through ...

Embodiment 2-12

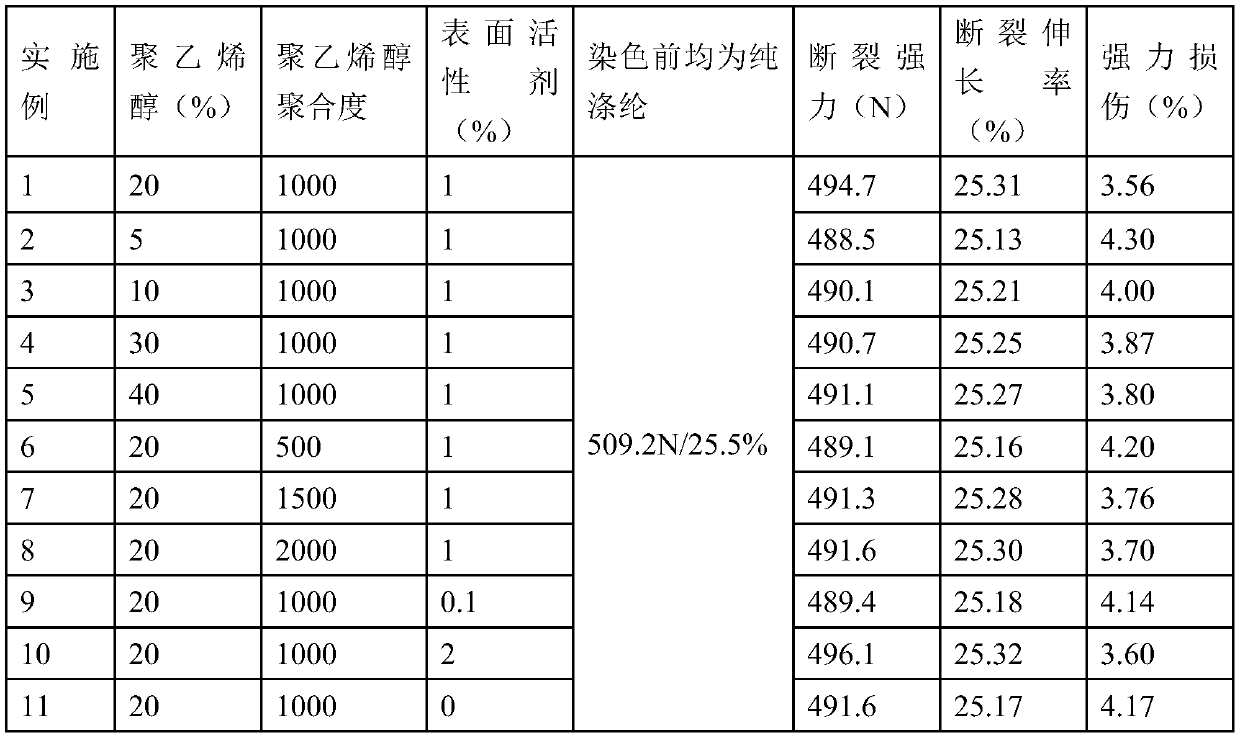

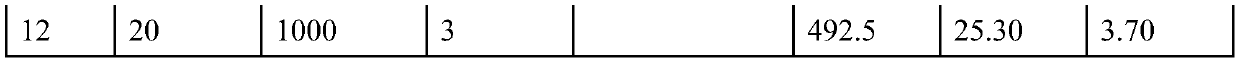

[0040] Embodiment 2-12 provides a kind of dyeing method of polyester textiles, compared with embodiment 1, the difference is that in step S1, the polyvinyl alcohol consumption, polyvinyl alcohol polymerization degree or the mass fraction of surfactant are changed, the specific dosage And the breaking strength and elongation at break of polyester textiles measured after dyeing are shown in the table below.

[0041]

[0042]

Embodiment 13-19

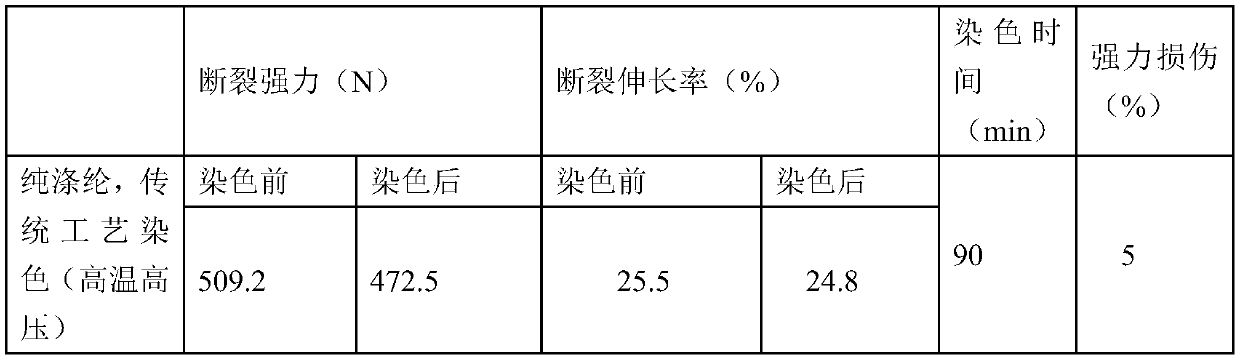

[0051] Embodiment 13-19 provides a kind of dyeing method of polyester textiles, compared with embodiment 1, the difference is that the stirring conditions in step S1 are changed, the specific condition parameters and the breaking strength and elongation at break of polyester textiles measured after dyeing The rates are shown in the table below.

[0052]

[0053] Comparing the breaking strength and elongation at break and the strength damage results of the dyed polyester textiles of Example 1 and Examples 13 to 14, it can be seen that with the increase of the mixing and stirring heating temperature in step S1, the breaking strength and elongation of the fabric after dyeing will increase. The elongation and strength damage properties are enhanced; when the temperature exceeds 70°C, the breaking strength and breaking elongation of the dyed fabric do not change much. Therefore, from the point of view of energy saving, the stirring and heating temperature in step S1 is preferabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com