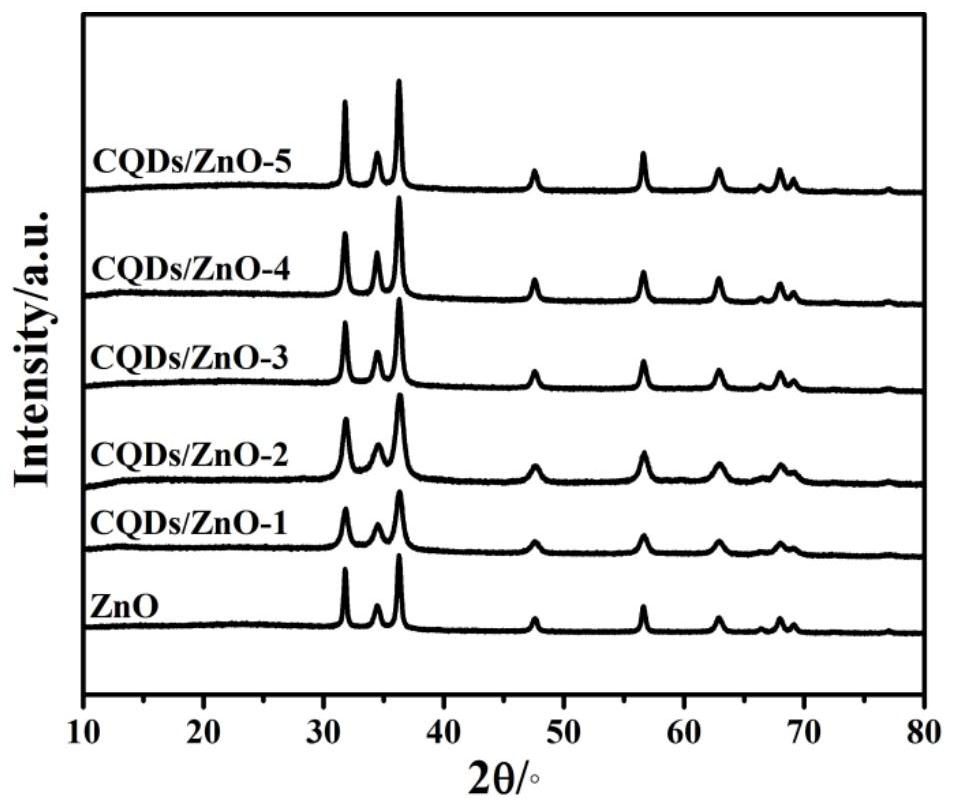

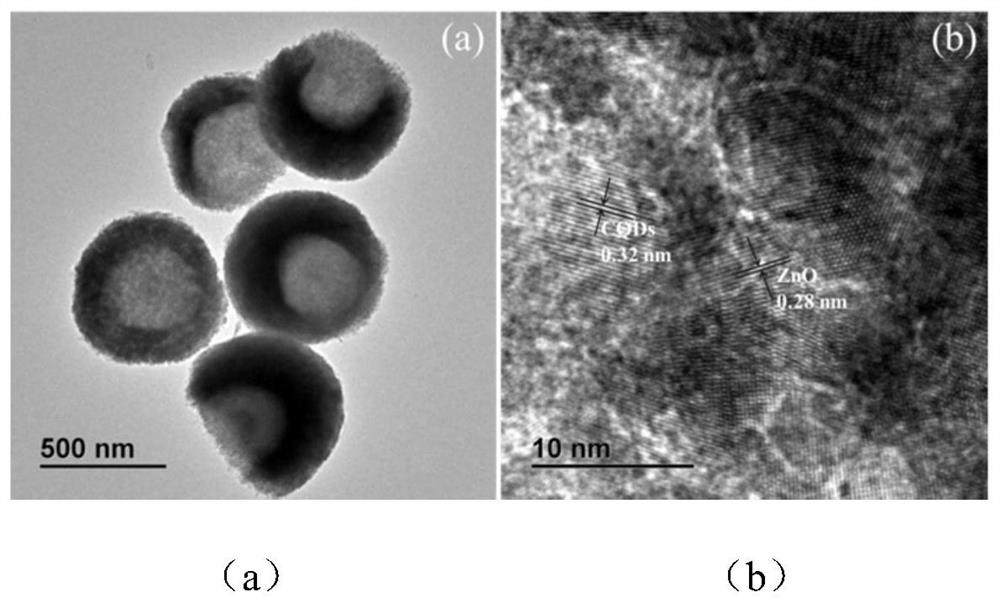

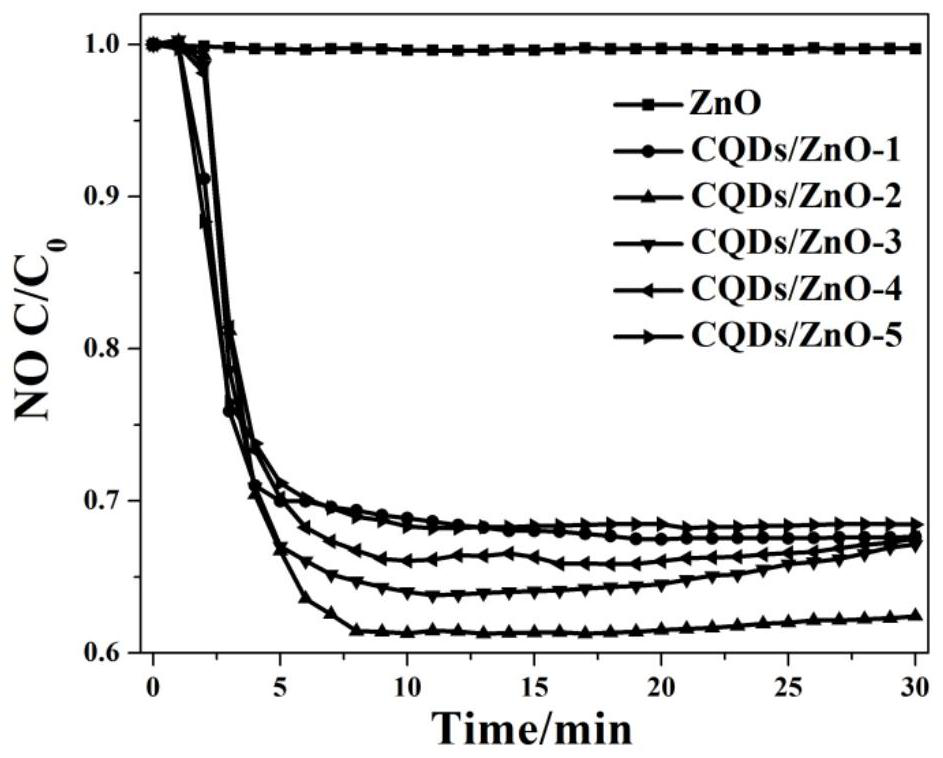

A kind of preparation method of carbon quantum dot/zinc oxide visible light catalyst

A technology of carbon quantum dots and zinc oxide, applied in the field of visible light catalytic material preparation and application, can solve the problems of low solar energy utilization efficiency, poor visible light catalytic performance, etc., and achieve the effect of improving visible light catalytic performance, improving visible light catalytic performance, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of a kind of carbon quantum dot / zinc oxide visible light catalyst of the present invention comprises the following steps:

[0024] (1) Preparation of carbon quantum dots:

[0025] Dissolve citric acid and urea in deionized water, stir evenly, and then transfer it to the reaction tube. Under the action of 500-750W, microwave hydrothermal reaction at 100-160°C for 2-30min, and naturally cool to room temperature to obtain carbon Quantum dot solution. Wherein, the concentrations of citric acid and urea in the deionized water are 0.1-5 mol / L and 1-10 mol / L respectively.

[0026] (2) Preparation of carbon quantum dots / zinc oxide:

[0027] Dissolve zinc salt and urea in deionized water, mix well to obtain a mixed aqueous solution, then add carbon quantum dot solution to the mixed aqueous solution, stir at room temperature for 10-90 minutes, transfer it to the reaction tube, and turn it into a reaction tube at a power of 500-850W Under the action of mi...

Embodiment 1

[0030] Transfer the aqueous solution of 0.1mol / L citric acid and 2mol / L urea into the reaction tube, under the action of 500W power, microwave hydrothermal reaction at 120°C for 15min, and naturally cool to room temperature to obtain the carbon quantum dot solution;

[0031] Add 1mL carbon quantum dot solution to 10mL aqueous solution of 2mol / L zinc nitrate and 0.1mol / L urea, stir at room temperature for 60min, then transfer to reaction tube, under the action of 500W power, microwave hydrothermal reaction at 100℃ for 60min, Naturally cooled to room temperature, washed with deionized water and ethanol respectively, and dried at 60°C to obtain carbon quantum dots / zinc oxide (CQDs / ZnO-1).

Embodiment 2

[0033] Transfer the aqueous solution of 5 mol / L citric acid and 6 mol / L urea into the reaction tube, under the power of 600W, conduct microwave hydrothermal reaction at 100°C for 30 minutes, and naturally cool to room temperature to obtain the carbon quantum dot solution;

[0034] Add 0.2mL carbon quantum dot solution to 50mL aqueous solution of 0.05mol / L zinc acetate and 5mol / L urea, stir at room temperature for 30min, transfer to the reaction tube, under the action of 750W power, microwave hydrothermal reaction at 140℃ for 30min , cooled naturally to room temperature, washed with deionized water and ethanol respectively, and dried at 80°C to obtain carbon quantum dots / zinc oxide (CQDs / ZnO-2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com