Preparation method of silver nanowire with high length-diameter ratio

A technology of silver nanowires and high aspect ratio, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of uneven aspect ratio and achieve high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

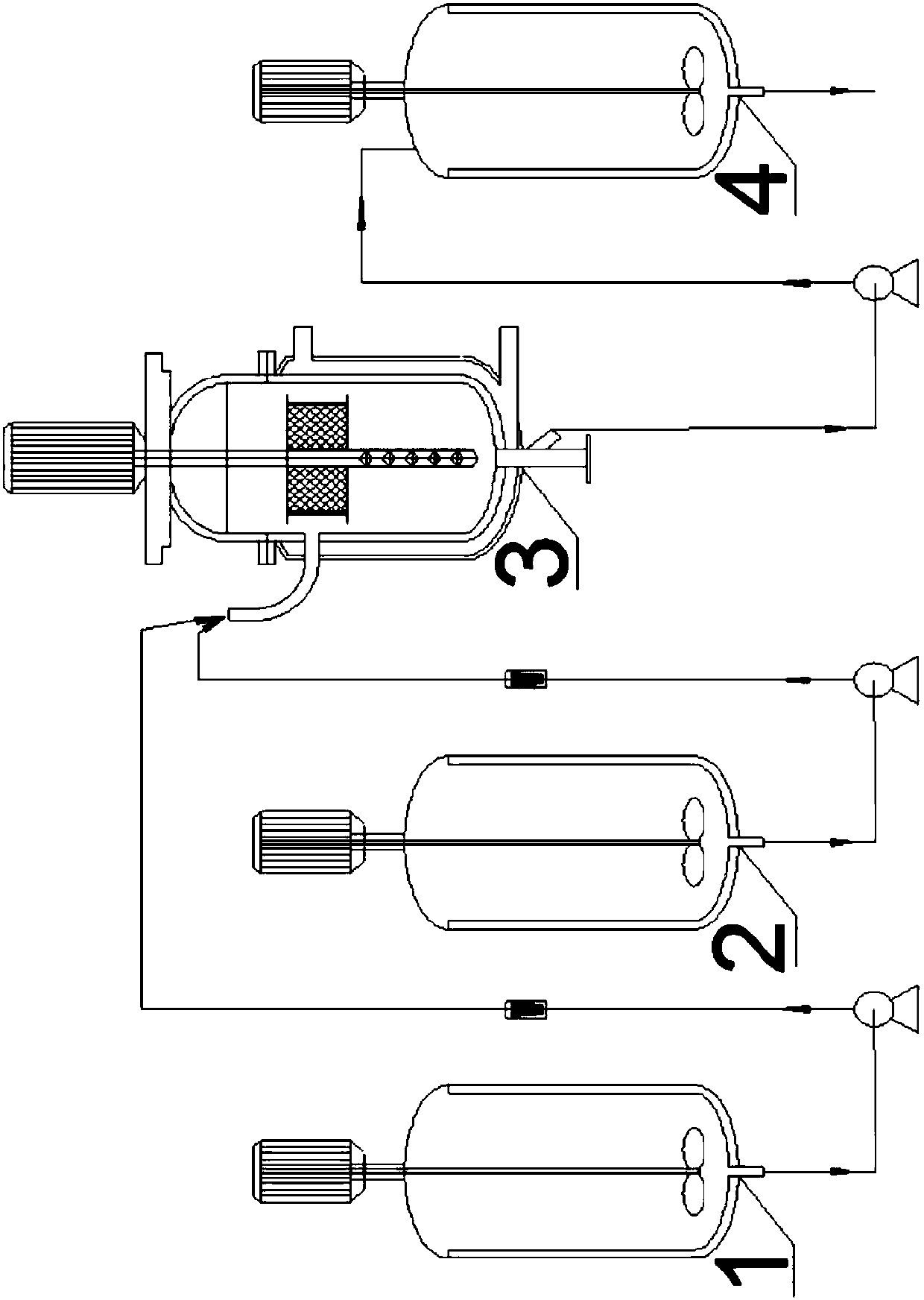

[0046] A kind of preparation method of silver nanowire with high aspect ratio of the present invention comprises the following steps:

[0047] S1. Take a surfactant and dissolve it in an organic solvent to obtain a solution A;

[0048] S2. Take the silver salt precursor and dissolve it in an organic solvent to obtain a solution B;

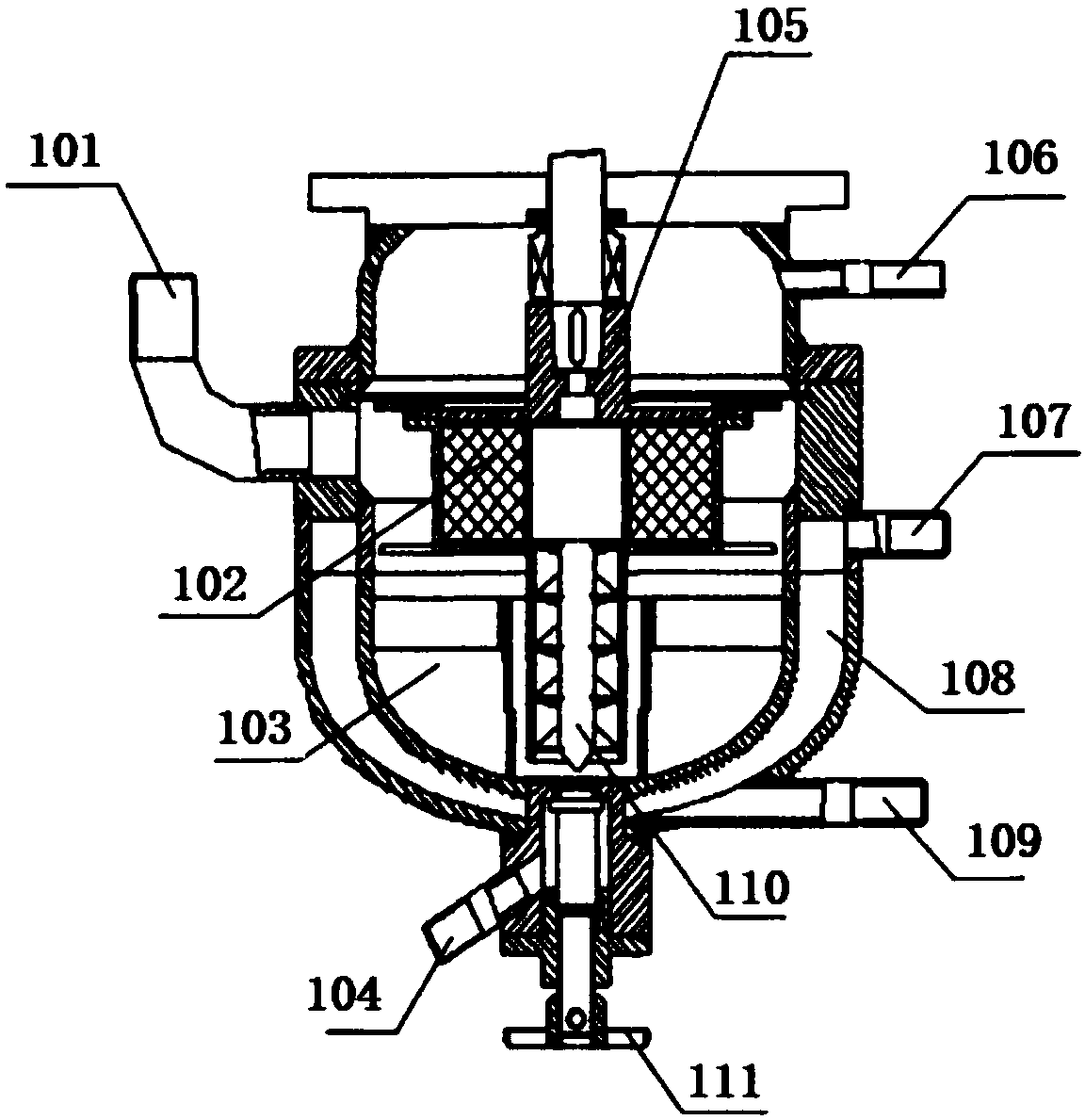

[0049] S3. Add solution A and solution B into the hypergravity reactor from the liquid inlet of the hypergravity reactor respectively, solution A and solution B are mixed and reacted in the packing layer of the hypergravity reactor, and a dispersed solution containing nanocrystalline nuclei is obtained. Liquid C, after circulating for a period of time, the dispersion C is discharged from the outlet;

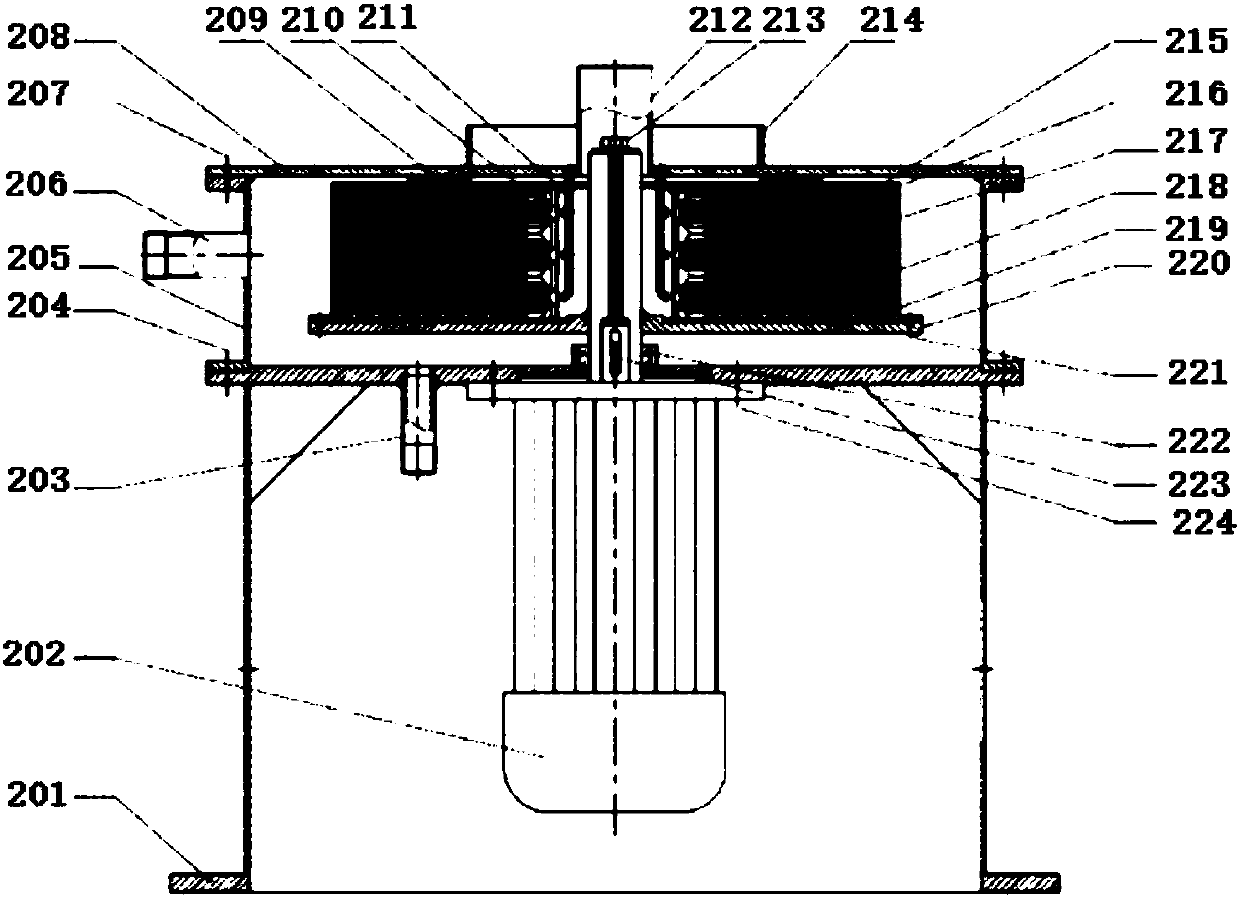

[0050] S4, transporting the dispersion C to a tank reactor, heating and stirring, and reacting to obtain a silver nanowire stock solution;

[0051] S5. Washing the silver nanowire stock solution with water and ethanol to remove redundant surfactants...

Embodiment 1

[0075] A high-gravity preparation method for silver nanowires with a high aspect ratio, comprising the following steps:

[0076] (1) Take 3g of polyvinylpyrrolidone K90, 24mg of sodium bromide, and 24mg of sodium chloride, add 80mL of ethylene glycol, and stir to obtain solution A;

[0077] (2) Take 0.5g of silver nitrate, add 20mL of ethylene glycol, and ultrasonically dissolve to obtain solution B;

[0078] (3) Add solution A and solution B into the hypergravity reactor, the hypergravity rotation speed is 1500rpm, mix and react at 80°C for 15min to obtain dispersion C;

[0079] (4) Transfer the dispersion C to a kettle reactor at 160°C, the reaction kettle speed is 200rpm, stop stirring after stirring for 30 minutes, and continue to react for 30 minutes;

[0080] (5) Washing the reaction product twice with deionized water and absolute ethanol respectively, and then adding polyacrylic acid to disperse in ethanol to obtain high-purity silver nanowires.

[0081] The target si...

Embodiment 2

[0086] Repeat Example 1, its difference is only: in the preparation process step (1) polyvinylpyrrolidone K90 is replaced with polyvinylpyrrolidone K30, consumption is promoted to 5g, silver nitrate is replaced with silver acetate in step (2), Other process parameters remained unchanged, and silver nanowires with a diameter of 30 nm and a length of 40 μm were prepared, with an aspect ratio of 1333.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com