Preparation method of coal tar wastewater demulsifier

The technology of a demulsifier and coal tar, which is applied in the field of preparation of a demulsifier for coal tar wastewater, can solve the problems of pipeline deposition, blockage, and high oil content of coal tar wastewater, and achieves less dosage, simple preparation method and good demulsification effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

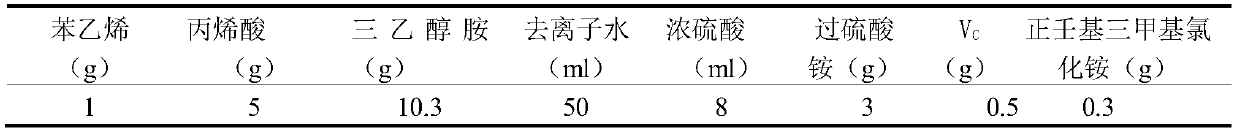

[0022] Add styrene, acrylic acid, triethanolamine, deionized water, concentrated sulfuric acid, ammonium persulfate, V C , n-nonyltrimethylammonium chloride was condensed and refluxed at 90°C for 6 hours and cooled to room temperature. It was observed that it was a liquid with a certain viscosity, and the demulsifier for coal tar wastewater was obtained.

[0023] Table 1

[0024]

Embodiment 2

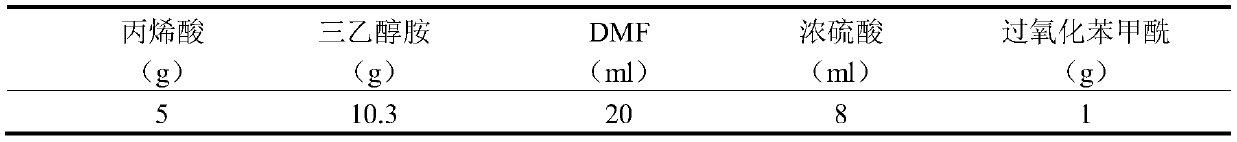

[0026] Add acrylic acid, triethanolamine, N,N-dimethylformamide (DMF), concentrated sulfuric acid, and benzoyl peroxide sequentially according to the amount in Table 2 while stirring, and condense and reflux at 90°C for 6 hours. After cooling to room temperature, it can be observed that the solution has a particularly high viscosity and turns dark brown in color. The viscous dark brown solution is the coal tar wastewater demulsifier.

[0027] Table 2

[0028]

Embodiment 3

[0030] Take acrylic acid, triethanolamine, toluene, concentrated sulfuric acid, and benzoyl peroxide in a three-necked flask according to the amount in Table 3, condense and reflux at about 110°C, and the solution turns into a yellow colloidal liquid. It is caramel in color. After reacting for 3h, hydroquinone was added. Reaction 6h, stop the reaction. After cooling to room temperature, the obtained caramel-colored colloidal liquid is the demulsifier for coal tar wastewater.

[0031] table 3

[0032]

[0033] Two, test the demulsification performance of the coal tar wastewater demulsifier prepared above:

[0034] The coal tar wastewater from Datuhe No. 3 Plant was put into a quartz cuvette, and the transmittance (T) before precipitation was measured to be 11.4%, and the absorbance (A) to be 0.941. Then add the coal tar wastewater demulsifier prepared above, stir, let stand for 0.5 hours, take the clear liquid and add it to a quartz cuvette, and measure the absorbance A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com