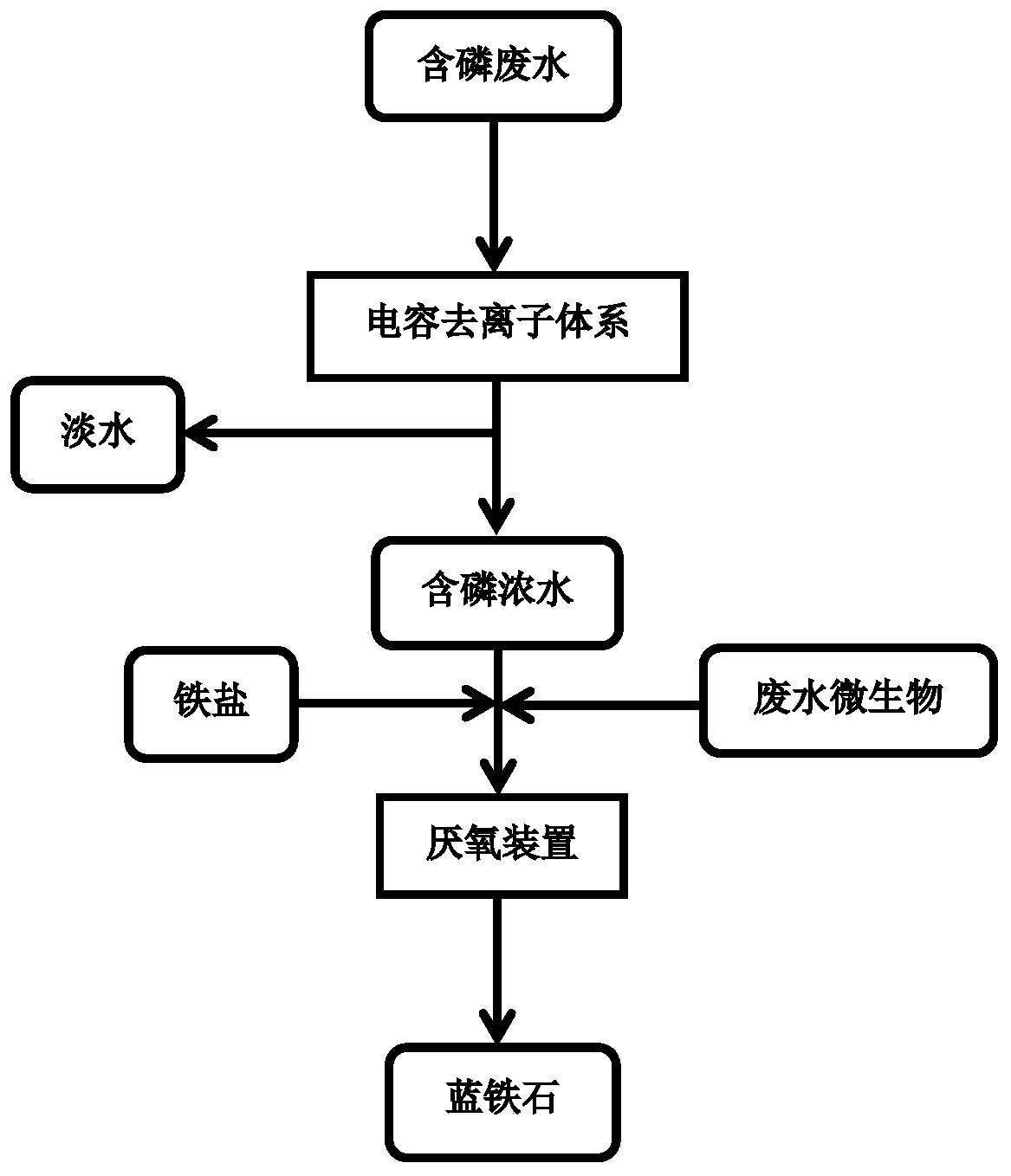

Method for recovering phosphorus by synthesizing blue-iron stone by means of combination of capacitive deionization and anaerobic iron reduction

A technology of capacitive deionization and blue iron, applied in separation methods, anaerobic digestion treatment, chemical instruments and methods, etc., can solve problems such as difficult crystallization, achieve great application potential, simple device structure, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method for recovering phosphorus based on anaerobic iron reduction synthesis of blue iron, the steps are as follows:

[0032] (1) Dissolve 0.31g L with 1.8mM potassium dihydrogen phosphate solution -1 NH 4 Cl, 0.13g L -1 KCl, 1.64g L -1 Sodium acetate, 2.88g·L -1 Ferric citrate, add 5ml·L -1 Vitamin solution and 12.5ml·L -1 After the trace element solution, adjust the pH to 7.6-8.0 with NaOH solution and distribute it into anaerobic bottles;

[0033] Wherein, the composition of vitamin solution is as shown in Table 1, and the composition of trace element solution is as shown in Table 2;

[0034] (2) Add the wastewater microorganisms collected by centrifugation (3000rpm, 5min), and use the dissimilatory iron reduction of microorganisms to reduce the ferric iron in the anaerobic system to ferrous iron, and then the ferrous iron and phosphate combine to form blue iron;

[0035] (3) Determination of soluble and extractable ferric content, ferrous content and phosph...

Embodiment 2

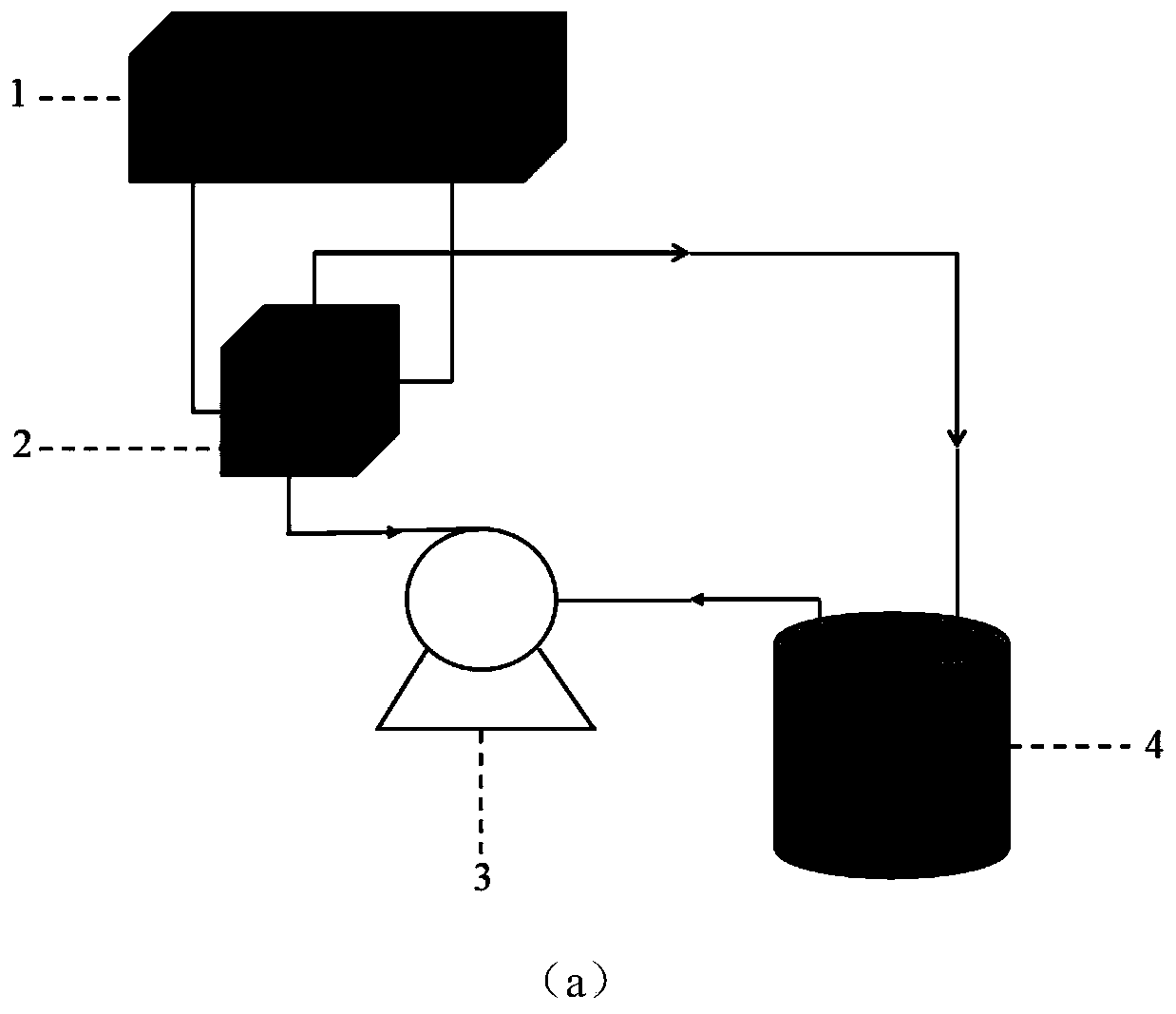

[0043] Concentration process based on capacitive deionization technology, the steps are as follows:

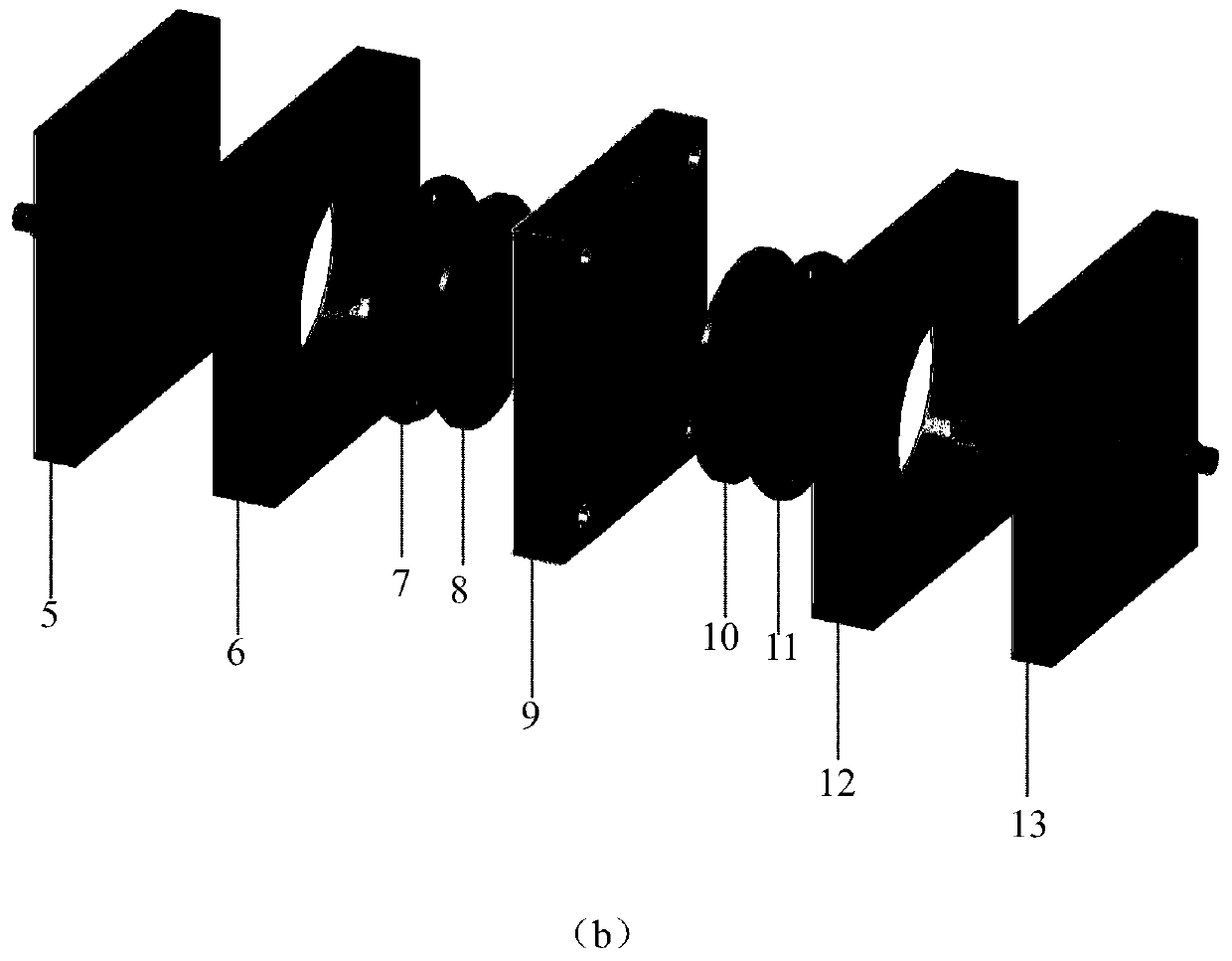

[0044] (1) Build a capacitive deionization device: use carbon material as the electro-adsorption material, titanium mesh as the current collector, non-woven fabric material as the grid and a DC power supply to construct the capacitive deionization device. The size of the CDI unit is 7cm×3cm×7cm;

[0045] (2) Capacitive deionization: adjust the DC power supply voltage to 1.2V. Under the action of a DC electric field, when the 1.8mM potassium dihydrogen phosphate solution passes through the flow channel between the electrodes of the capacitive deionization component, the polarity of anion and cation in the water will The opposite electrode moves directional and attaches to the electrode. When the ions adsorbed on the electrode reach saturation, the phosphate ions adsorbed on the electrode are desorbed from the capacitor electrode under the action of the reverse electric field th...

Embodiment 3

[0048] Based on capacitive deionization combined with anaerobic iron reduction to synthesize blue iron phosphorus recovery method, the steps are as follows:

[0049] (1) Build a capacitive deionization device: use carbon material as the electro-adsorption material, titanium mesh as the current collector, non-woven fabric material as the grid and a DC power supply to construct the capacitive deionization device. The size of the CDI unit is 7cm×3cm×7cm;

[0050] (2) Capacitive deionization: adjust the DC power supply voltage to 1.2V. Under the action of a DC electric field, when the 1.8mM potassium dihydrogen phosphate solution passes through the flow channel between the electrodes of the capacitive deionization component, the polarity of anion and cation in the water will The opposite electrode moves directional and attaches to the electrode. When the ions adsorbed on the electrode reach saturation, the phosphate ions adsorbed on the electrode are desorbed from the capacitor el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com