Waterborne low surface tension high viscosity radioactive aerosol suppressant and preparation method

A technology with low surface tension and radioactivity, which is applied in the field of nuclear pollution decontamination, can solve the problems of compression preparations that need to be improved, low surface tension, and large surface tension of droplets, etc. The effect of peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

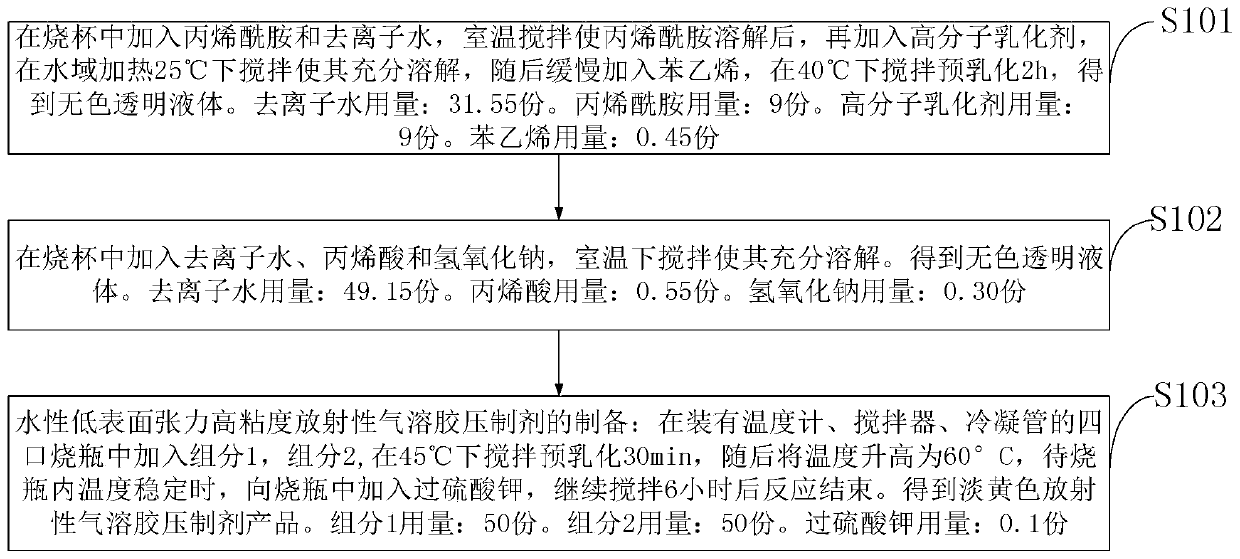

[0034] Such as figure 1 As shown, the preparation method of the water-based low-surface tension high-viscosity radioactive aerosol press preparation of the embodiment of the present invention is based on 50 parts of the mass of the synthesized component 1 or component 2, and specifically includes the following steps:

[0035] S101: Add acrylamide and deionized water into the beaker, stir at room temperature to dissolve the acrylamide, then add polymer emulsifier, heat in a water bath at 25°C and stir to fully dissolve, then slowly add styrene, at 40°C Stir and pre-emulsify for 2h to obtain a colorless transparent liquid. Deionized water dosage: 31.55 parts. Acrylamide dosage: 9 parts. The amount of polymer emulsifier: 9 parts. Styrene dosage: 0.45 parts.

[0036] S102: Add deionized water, acrylic acid and sodium hydroxide into the beaker, stir at room temperature to fully dissolve. A colorless transparent liquid was obtained. Deionized water dosage: 49.15 parts. Acryli...

Embodiment 1

[0044] Polymer emulsifier synthesis, including:

[0045] Preparation of component 3 solution: Add 9g of acrylamide and 31.55g of deionized water into a 100ml beaker, stir at room temperature to dissolve the acrylamide, then add 9g of sodium lauryl sulfate, heat in a water bath at 25°C and stir to fully Dissolve, then slowly add 0.45g styrene, stir and pre-emulsify at 40°C for 2h to obtain a colorless transparent liquid.

[0046] Preparation of component 4 solution: Add 49.05g of deionized water, 0.55g of acrylic acid and 0.30g of sodium hydroxide into a 100ml beaker, stir at room temperature to fully dissolve. Subsequently, 0.1 g of potassium persulfate as an initiator was added, heated and stirred in a water bath at 25° C. to dissolve evenly, and a colorless transparent liquid was obtained.

[0047] Preparation of solid polymer emulsifier: Add 50g of component 3 and 50g of component 4 into a 250ml four-neck flask equipped with a thermometer, agitator, and condenser, stir and...

Embodiment 2

[0049] In an embodiment of the present invention, the preparation of the radioactive aerosol compressed preparation includes:

[0050] The preparation method of component 1: Add 9g of acrylamide and 31.55g of deionized water into a 100ml beaker, stir at room temperature to dissolve the acrylamide, then add 9g of polymer emulsifier, heat in a water bath at 25°C and stir to fully dissolve, Then slowly add 0.45g of styrene, and stir and pre-emulsify at 40°C for 2h to obtain a colorless transparent liquid.

[0051] The preparation method of component 2: add 49.15g of deionized water, 0.55g of acrylic acid and 0.30g of sodium hydroxide into a 100ml beaker, stir at room temperature to fully dissolve. A colorless transparent liquid was obtained.

[0052] Preparation of radioactive aerosol compression preparation: Add 50g of component 1 and 50g of component 2 into a 250ml four-neck flask equipped with a thermometer, agitator, and condenser tube, stir and pre-emulsify at 45°C for 30mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com