Solid polymer electrolyte containing sulfonic acid or phosphoric acid derivative structure and its application in secondary lithium battery

A solid polymer, phosphoric acid derivative technology, applied in secondary batteries, solid electrolytes, non-aqueous electrolytes, etc., can solve problems such as performance that cannot meet application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

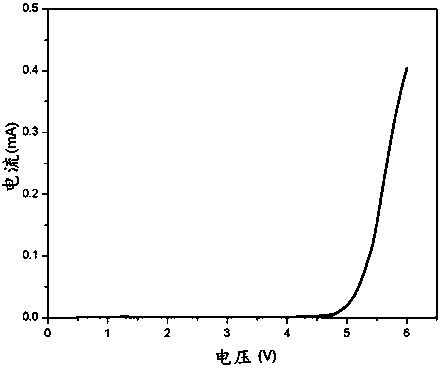

[0051] In a glove box, under an inert atmosphere, configuration P1 (m = 20, n = 100) dimethyl sulfoxide solution, the polymer accounted for about 80% of the solution mass fraction. The solution was thoroughly stirred to obtain a clear and transparent viscous liquid. Scrape the above solution evenly on the seaweed fiber non-woven membrane, set it at 60 o Dry in a C oven for 12 h to form a film. After punching, the electrolyte membrane was dried in a vacuum oven for 12 h, and then soaked in an organic solvent (vinylene carbonate) for 24 h. Depend on figure 1 It can be seen that the polymer electrolyte has an electrochemical window of 0-4.7 V.

[0052]

Embodiment 2

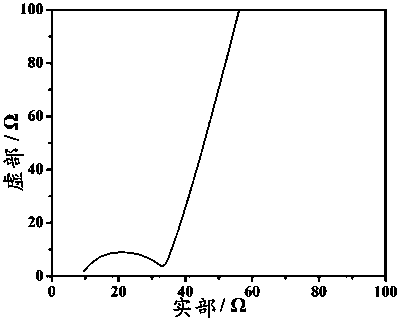

[0054] In a glove box, under an inert atmosphere, configure P2 (m=20, n=20), LiDFOB and silicon dioxide N , N -Dimethylformamide solution, the polymer accounts for about 40% of the mass fraction of the solution. The solution was thoroughly stirred to obtain a clear and transparent viscous liquid. Scrape the above solution evenly on the tetrafluoroethylene plate, set it at 70 o Dry in a C oven for 10 h to form a film. After punching, the electrolyte membrane was dried in a vacuum oven for 20 h, and then placed in a glove box for use. Depend on figure 2 The electrochemical impedance spectroscopy shows that the room temperature ionic conductivity of the electrolyte membrane is 1.04 × 10 -5 S / cm.

[0055]

Embodiment 3

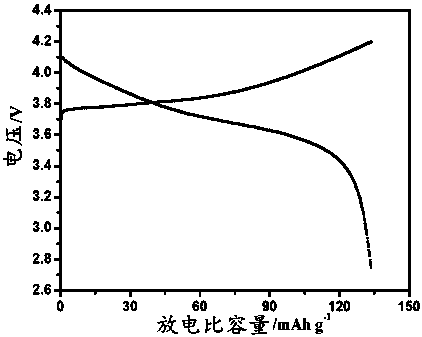

[0057] In a glove box, under an inert atmosphere, configure P3 (m=50, n=100) and titanium dioxide N , N -Dimethylacetamide solution, the polymer accounts for about 10% of the mass fraction of the solution. The solution was thoroughly stirred to obtain a clear and transparent viscous liquid. Scrape the above solution evenly on the cellulose, set at 80 o Dry in a C oven for 24 h to form a film. After punching, the electrolyte membrane was dried in a vacuum oven for 24 h, and then soaked in sulfolane for 24 h. Depend on image 3 As shown, the ternary material (type 622) / lithium battery assembled with the electrolyte membrane still maintains a discharge specific capacity of 135 mAh / g after 50 cycles at room temperature at 1 C.

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com