Method for improving performances and thermostability of perovskite solar cell module

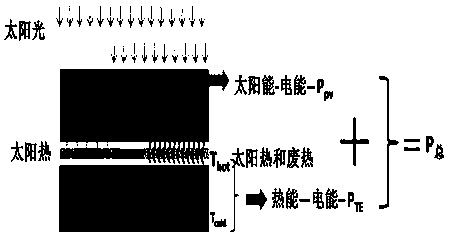

A technology for solar cell components and perovskite cells, which is applied in the field of improving the performance and thermal stability of perovskite solar cell components, and can solve the problem of inability to replicate the photoelectric conversion efficiency of small-area cells, reduce the photoelectric conversion performance and stability of cells, and prevent calcium Problems such as the increase of internal defects in the titanium ore structure, etc., achieve high output power, increase power output, and increase output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

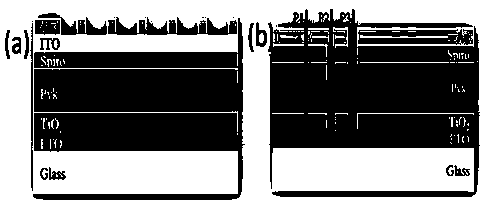

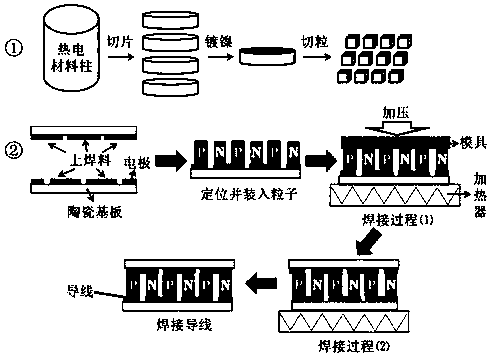

[0033] Preparation of large-area perovskite cells (NanoLett., 2014, 14, 2591-2596.): Three laser etching processes (see figure 2 ), first place the FTO substrate (4*4cm 2 ) use the first laser P1 to etch the surface of the substrate, form the required pattern with the surface of the substrate, and divide the substrate into several unconnected sub-cells through the pattern; magnetron sputtering 50nm thick TiO 2 Electron transport layer; 300nm thick large-area methylamino lead iodide perovskite film was prepared by vacuum evaporation and direct contact reaction method; spin-coated 200nm thick hole transport layer Spiro-OMeTAD, followed by the first laser on it The corresponding pattern laser P2 is etched; secondly, the metal is evaporated to ensure that the metal top electrode of the second sub-cell and the FTO bottom electrode of the first sub-cell are in contact with each other when the metal electrode is evaporated, and so on, the nth sub-cell The metal top electrode and th...

Embodiment 2

[0038] Prepare large-area (4*4cm) according to embodiment 1 2 ) perovskite solar cell assembly method to prepare six sub-cells with equal effective area. The assembly structure of the large-area perovskite solar cell prepared by combining series and parallel (3s2p), the effective area of the sub-cell is 7.56cm 2 Carry out I-V test to this type of battery, the output current of device is 35.69mA, open circuit voltage 2.9V, fill factor is 47%, and maximum output power reaches 48.94mW; Prepare thermoelectric power generation device according to embodiment 1, it is according to Figure 5 The connection mode shown in series, that is, the negative electrode of the solar cell and the positive electrode of the thermoelectric power generation device are connected to each other to prepare a coupling device. The short-circuit current of the final coupling device is 40.27mA, the open circuit voltage is 3.48V, the fill factor is 43%, and the maximum output power reaches 60.64mW, the outp...

Embodiment 3

[0040] The connection mode of the perovskite cell module (PSM) and the thermoelectric generator module (TEG) can be connected in series or in parallel, according to the characteristics of the series-parallel circuit: when the perovskite cell module and the thermoelectric module are connected in series, the final output open voltage is the sun The sum of the output open voltages of the battery and the thermoelectric module; when the solar cell and the thermoelectric power generation device are connected in parallel, the coupled current is the sum of the output current of the solar cell and the thermoelectric module. As a guide for experiments, under the premise of knowing the performance of perovskite battery components and thermoelectric power generation devices, we develop a simulation estimation method to find the optimal connection method to obtain the maximum power output.

[0041] Prepare large-area (4*4cm) according to embodiment 1 2 ) perovskite solar cell components an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Effective area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com