Composite body having coating layer of ceramic crystal, and method for producing same

A manufacturing method and composite technology, applied in the direction of ceramic layered products, chemical instruments and methods, phosphorus compounds, etc., can solve the problem of describing the thickness of the uncoated layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 0.005 g of gelatin (manufactured by Nippi, HMG-BP) was dispersed in 65 mL of distilled water. 10 mL of 0.018 mol / L calcium acetate aqueous solution was added to this dispersion liquid, it stirred at 300 rpm for 5 minutes using a magnetic stirrer, and 25 mL of 0.003 mol / L diammonium hydrogen phosphate aqueous solution was further added and stirred. Thereafter, the mixture was stirred at 300 rpm for 24 hours using a magnetic stirrer to obtain an aqueous dispersion of a complex in which calcium phosphate crystals were coated on the surface of gelatin. The dispersion was subjected to solid-liquid separation by centrifugation, and then freeze-dried to obtain core-shell particles.

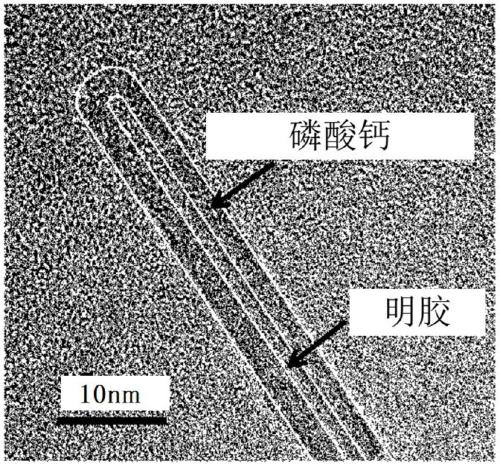

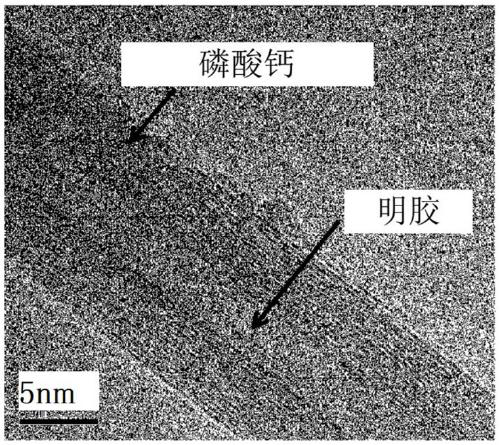

[0033] figure 1 A transmission electron micrograph of the core-shell particles is shown. From this photograph, it was confirmed that the core, that is, the surface of the gelatin fiber was uniformly covered with a shell of ceramic crystals with a thickness of about 5 nm. figure 2 It is a transmi...

Embodiment 2

[0035] Add 50 mg of bovine serum albumin (manufactured by Sigma, Bovine Serum Albumin, BSA) to 100 mL of 0.010 mol / L calcium acetate aqueous solution, stir at 300 rpm for 5 minutes using a magnetic stirrer, and further dropwise add 100 mL of 0.006 mol / L hydrogen phosphate diammonium solution and stirred. Thereafter, the mixture was stirred at 300 rpm for 3 hours using a magnetic stirrer to obtain an aqueous dispersion of a complex in which calcium phosphate crystals were coated on the surface of BSA. After filtering the dispersion, freeze-drying was performed to obtain core-shell particles.

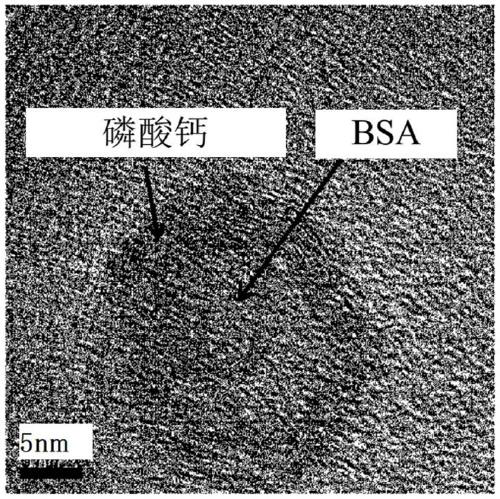

[0036] image 3 A transmission electron micrograph of the core-shell particles is shown. From this photograph, it was confirmed that a shell of ceramic crystals with a thickness of about 5 nm was uniformly coated on the surface of BSA as the core. In addition, from a lattice image obtained by a transmission electron microscope, it was found that hydroxyapatite was laminated in the c-ax...

Embodiment 3

[0038] 0.05 g of pectin (manufactured by Wako Pure Chemical Industries, 164-00552) was dispersed in 160 mL of distilled water. 20 mL of 0.080 mol / L calcium acetate aqueous solution was added to this dispersion liquid, and it stirred at 300 rpm for 5 minutes using the magnetic stirrer. Furthermore, 25 mL of 0.048 mol / L diammonium hydrogen phosphate aqueous solution was added and stirred. Thereafter, the mixture was stirred at 300 rpm for 24 hours using a magnetic stirrer to obtain an aqueous dispersion of core-shell particles in which hydroxyapatite crystals were formed on the surface of the pectin. The aqueous dispersion was subjected to solid-liquid separation by centrifugation, and then the solid matter was freeze-dried to obtain core-shell particles having a width of about 20 nm and a length of about 500 nm.

[0039] Figure 4 A transmission electron micrograph of the core-shell particles is shown. From this photograph, it was confirmed that a shell of ceramic crystals w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com