A kind of insecticidal composition of dinotefuran and bifenthrin and application thereof

An insecticidal composition, bifenthrin technology, applied to fruit trees, insecticidal composition containing dinotefuran and bifenthrin, application on vegetable pests, insecticidal composition, control of food crops, can Solve the problems of drug efficacy reduction and achieve the effects of improving drug efficacy, excellent performance, and delaying drug resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

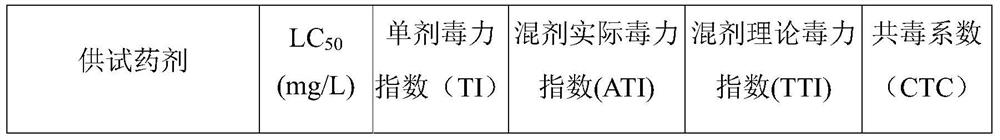

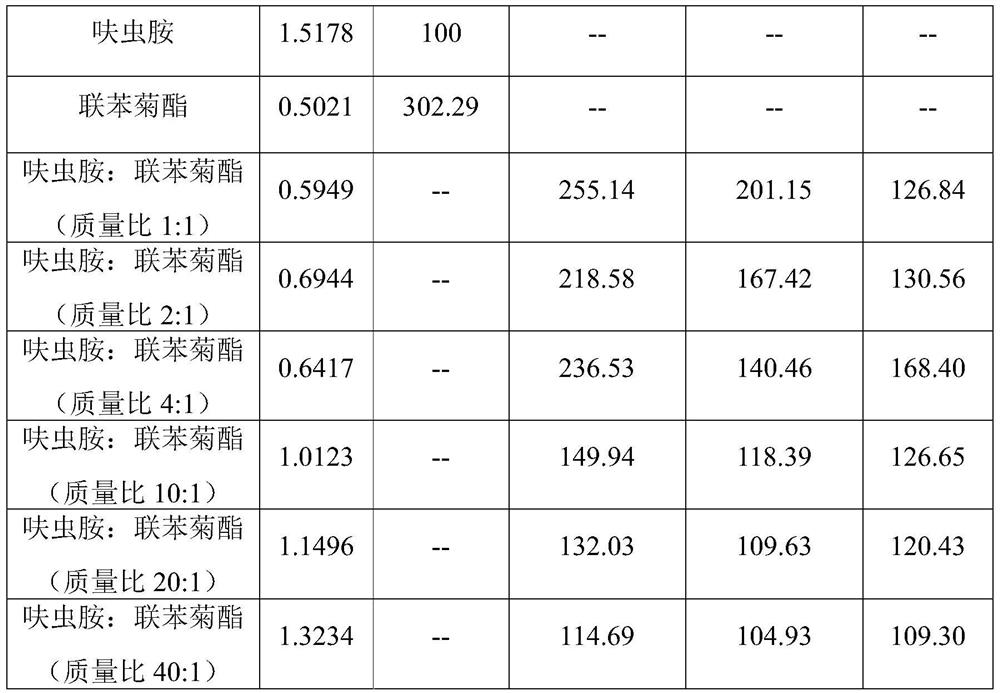

Image

Examples

Embodiment 1

[0053] Example 1 10% dinotefuran bifenthrin wettable powder

[0054] The formula is: dinotefuran 5%, bifenthrin 5%, dispersant sodium alkyl polyoxyethylene ether sulfate 1.25%, naphthalenesulfonic acid formaldehyde condensate sodium salt 1.25%, wetting agent diisobutylnaphthalenesulfonic acid Sodium 1.5%, sodium lauryl sulfate 1.0%, anti-caking agent white carbon black 7%, filler kaolin 15%, anhydrous sodium sulfate added to 100%.

[0055] The preparation method is as follows: mix dinotefuran, bifenthrin, dispersant, wetting agent, anti-caking agent and filler in a mixer evenly, and pulverize it with a jet mill until the particle size is 20-30 μm, and then carry out secondary Mix and mix evenly to obtain dinotefuran bifenthrin wettable powder.

Embodiment 2

[0056] Example 2 30% dinotefuran bifenthrin wettable powder

[0057] The formula is: dinotefuran 20%, bifenthrin 10%, dispersant sodium alkyl polyoxyethylene ether sulfate 1.25%, naphthalenesulfonic acid formaldehyde condensate sodium salt 1.25%, wetting agent diisobutylnaphthalenesulfonic acid Sodium 1.25%, sodium lauryl sulfate 1.25%, anti-caking agent white carbon black 7%, filler kaolin 15%, anhydrous sodium sulfate added to 100%. The preparation method is the same as in Example 1.

Embodiment 3

[0058] Example 3 45% dinotefuran bifenthrin wettable powder

[0059] The formula is: dinotefuran 36%, bifenthrin 9%, dispersant sodium alkylpolyoxyethylene ether sulfate 1.5%, naphthalenesulfonic acid formaldehyde condensate sodium salt 1.0%, wetting agent diisobutylnaphthalenesulfonic acid Sodium 1.25%, sodium lauryl sulfate 1.25%, anti-caking agent white carbon black 7%, filler kaolin 15%, anhydrous sodium sulfate added to 100%. The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com