PI short-cut fiber reinforced flexible silicon dioxide aerogel composite material and preparation method thereof

A composite material and silicon dioxide technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of inability to achieve effective control of composite material mechanics, thermal and sound insulation performance, separation of matrix and fiber, poor bonding effect, etc. problems, to achieve the effect of safe and controllable production process, improve mechanical properties, and reduce raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

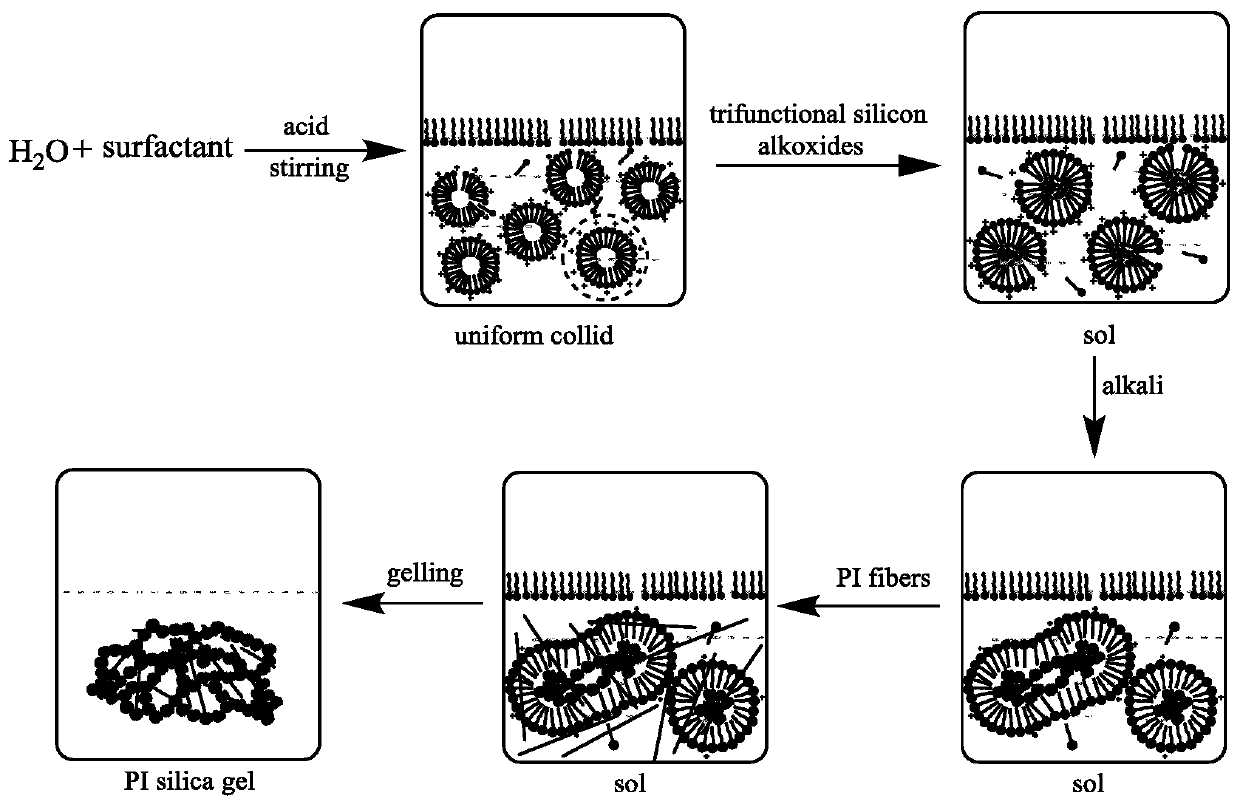

[0047] The invention discloses a method for preparing a PI chopped fiber reinforced flexible silica airgel composite material, which comprises the following steps:

[0048] 1) Prepare micelles or microemulsions: add 30mL deionized water to a beaker, then add an acidic catalyst to make the solution pH = 3-4, stir for 5 minutes, add 0.1-5g surfactant, and stir for 20-60 minutes;

[0049] 2) Preparation of sol: Add silicon source according to the volume ratio of silicon source and deionized water as 1: (0.5~6), continue stirring at room temperature for 3~5 hours, and then add a certain amount of molar concentration of 1~6.5mol / L ammonia water until the solution pH=7~8, and continue to stir for 0.5~1h;

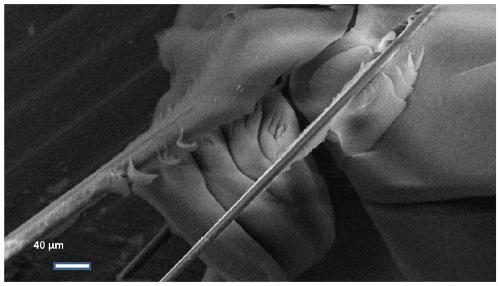

[0050] 3) Add reinforcement phase: place the sol in a water bath at 40-80°C, and observe its viscosity value through a viscometer. The kinematic viscosity of the sol is 20-50mm 2 / s, add 0.01~0.2g of polyimide fiber with a length of 3~10mm, stir evenly, and wait for the gel;

[...

Embodiment 1

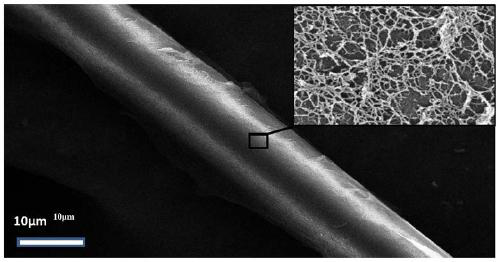

[0055] Add 30mL deionized water to the beaker, then add acetic acid to make the solution pH=3~4, stir for five minutes, add 0.4g cetyltrimethylammonium bromide CTAB, stir for 20min, then add 7.5mL methyl triethyl ammonium bromide Oxysilane MTES, continue to stir at room temperature for 4h. Then add a certain amount of ammonia water with a molar concentration of 1 mol / L until the pH of the solution is 7, and continue stirring for 1 h. Place the sol in a 60°C water bath, and observe its viscosity value through a viscometer. The kinematic viscosity of the sol is 20mm 2 / s, add 0.1g of polyimide fiber with a length of 3mm, and stir evenly, waiting for the gel. The wet gel was aged at 60 °C for two days, followed by replacement with deionized water for 8 h in a 60 °C water bath to remove surfactants and other unreacted substances. After replacement, replace with ethanol 3 times at room temperature, 12 hours each time. Finally with CO 2 SiO obtained by supercritical drying 2 ai...

Embodiment 2

[0057] Add 30mL deionized water to the beaker, then add acetic acid to make the solution pH=3~4, stir for five minutes, add 0.2g cetyltrimethylammonium bromide CTAB, stir for 20min, then add 7.5mL methyl triethyl ammonium bromide Oxysilane MTES, continue to stir at room temperature for 4h. Then add a certain amount of ammonia water with a molar concentration of 1mol / L until the pH of the solution is 7, continue to stir for 1 hour, place the sol in a water bath at 60°C, and observe its viscosity value with a viscometer until the viscosity of the sol is 25mm 2 / s, add 0.1g of polyimide fibers with a length of 5mm, and stir evenly, waiting for the gel. The wet gel was aged at 60 °C for two days, followed by replacement with deionized water for 8 h in a 60 °C water bath to remove surfactants and other unreacted substances. After replacement, replace with ethanol 3 times at room temperature, 12 hours each time. Finally with CO 2 SiO obtained by supercritical drying 2 airgel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com