Fluorine-containing hydroxylpolyacrylate aqueous dispersion with high solid content and preparation method and application thereof

A fluorine-containing hydroxyl polyacrylate, high solid content technology, used in polyurea/polyurethane coatings, biocide-containing paints, antifouling/underwater coatings, etc. To solve problems such as performance, to achieve the effect of excellent solvent resistance, low VOC, and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

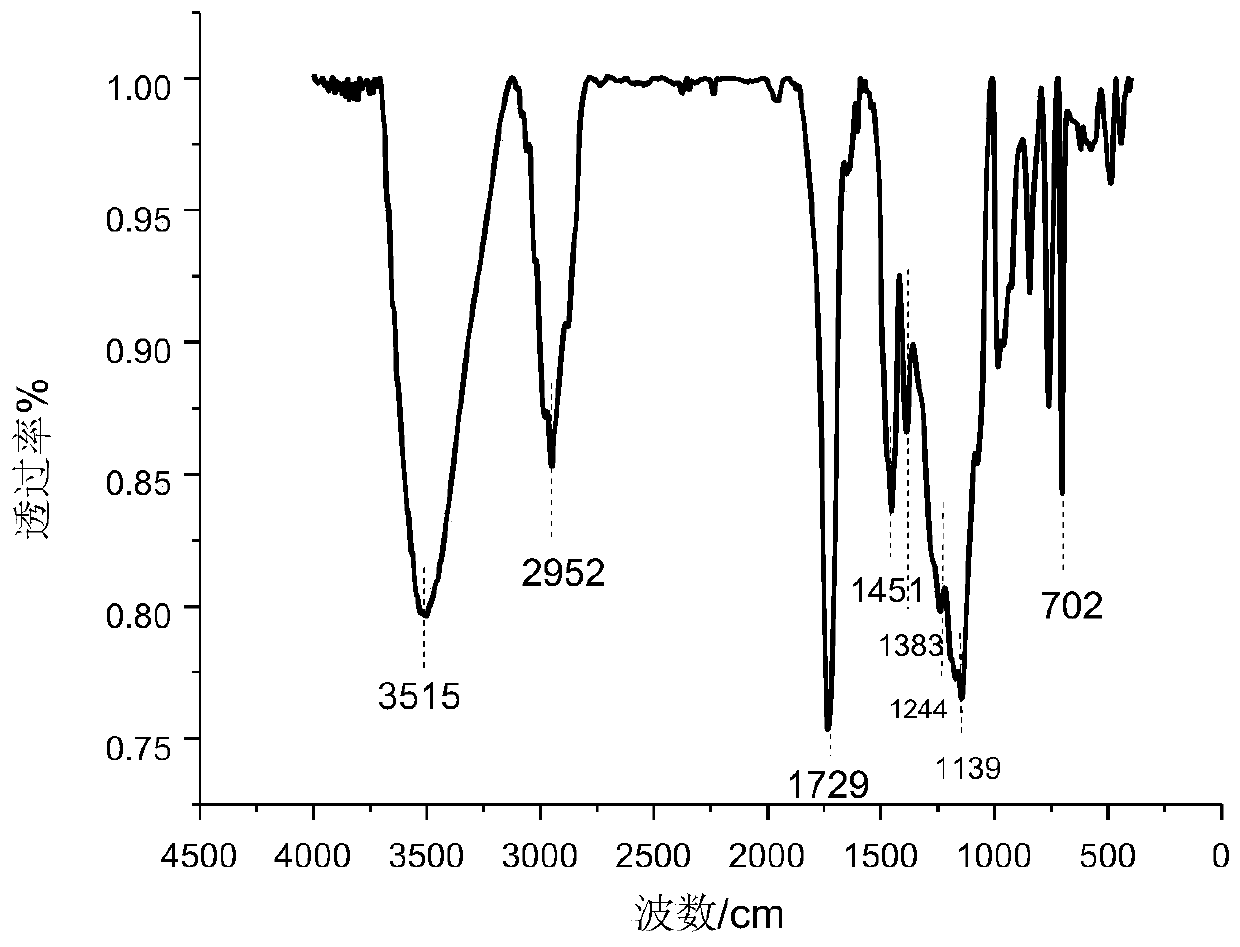

Image

Examples

Embodiment 1

[0040] 1) Preparation of high solid content fluorine-containing hydroxyl polyacrylate aqueous dispersion

[0041] In parts by mass, the raw material components and consumption are as follows in Table 1

[0042] Table 1

[0043]

[0044] Preparation: Under nitrogen protection, mix vinyl fluoride monomer, vinyl sulfonate monomer, acrylic monomer, initiator and chain transfer agent to prepare a mixed solution, add 10% of the mixed solution to the reactor, Stir and heat up to 70°C for 30 minutes, add the remaining mixture into the reactor within 4 hours, and keep it warm for 2 hours to obtain a fluorine-containing hydroxyl polyacrylate prepolymer; then lower the temperature to below 50°C, add a neutralizing agent for neutralization, and add water High-speed dispersion was carried out at 1000 rpm at 30°C to prepare an aqueous dispersion.

[0045] Performance of high solid content fluorine-containing hydroxyl polyacrylate aqueous dispersion: solid content is 45%, viscosity (25°...

Embodiment 2

[0057] (1) Preparation of high solid content fluorine-containing hydroxyl polyacrylate aqueous dispersion

[0058] In terms of parts by mass, the raw material components and consumption are as shown in Table 3

[0059] table 3

[0060]

[0061]

[0062] Preparation of vinyl fluoride monomer-modified polyacrylate: under nitrogen protection, mix vinyl fluoride monomer, vinyl sulfonate monomer, acrylic monomer, initiator and chain transfer agent to prepare a mixed solution, Add 10% mixed solution into the reactor, stir and raise the temperature to 75° C. for 30 minutes, add the remaining mixture into the reactor within 4 hours, and keep it warm for 1.5 hours to obtain a fluorohydroxypolyacrylate prepolymer. Then lower the temperature to below 50°C, add a neutralizing agent for neutralization, add water and disperse at a high speed of 1500 rpm at 30°C to obtain an aqueous dispersion.

[0063]Vinyl fluoride monomer-modified polyacrylate aqueous dispersion properties: solid ...

Embodiment 3

[0071] (1) Preparation of high solid content fluorine-containing hydroxyl polyacrylate aqueous dispersion

[0072] In parts by mass, the raw material components and consumption are as shown in Table 5

[0073] table 5

[0074]

[0075] Preparation of vinyl fluoride monomer modified polyacrylate: under nitrogen protection, vinyl fluoride monomer, vinyl silicon monomer, vinyl sulfonate monomer, acrylic monomer, initiator and chain transfer agent Mix to prepare a mixed solution, add 15% of the mixed solution to the reactor, stir and heat up to 75°C for 35 minutes, add the remaining mixture to the reactor within 5 hours, and keep it warm for 1.5 hours to obtain vinyl fluoride monomer-modified Polyacrylate prepolymer. Then lower the temperature to below 50°C, add a neutralizing agent for neutralization, add water at 30°C and perform high-speed dispersion at 2500 rpm to obtain an aqueous dispersion.

[0076] Vinyl fluoride monomer-modified polyacrylate aqueous dispersion prope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com