Simulation plant and preparation method thereof

A plant simulation and simulation technology, applied in applications, inks, household appliances, etc., can solve the problems of poor corrosion resistance, poor coloring performance, low production efficiency, etc., to reduce molding time, save labor costs, and improve productivity. fast delivery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

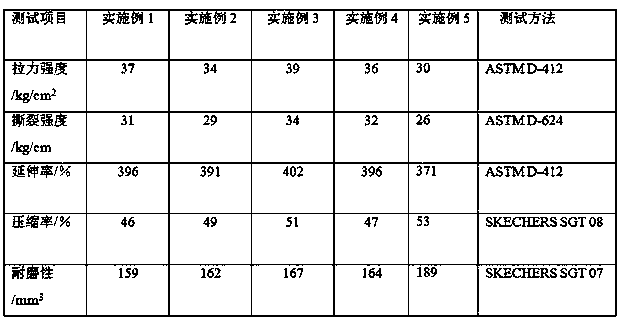

Examples

Embodiment 1

[0047] In the present embodiment, a kind of simulation plant is made by simulation composite material, and simulation composite material comprises the raw material of following weight portion: ethylene-vinyl acetate copolymer 83 parts, polyethylene 10 parts, talcum powder 4.2 parts, zinc oxide powder 12 parts part, 0.5 part of lubricant, 0.5 part of foaming agent, and 0.8 part of crosslinking agent.

[0048] Further, the foaming agent is azodicarbonamide, and the crosslinking agent is dicumyl peroxide.

[0049] Further, the content of vinyl acetate in the ethylene-vinyl acetate copolymer is less than 18wt%. The ethylene-vinyl acetate copolymer is EVA5110M. The polyethylene is polyethylene POE565.

[0050] Further, the lubricant is compounded by stearic acid and zinc stearate in a mass ratio of 1:1.

[0051] Further, the simulated plant also includes 7 parts by weight of a composite synergist, and each part of the composite synergist is composed of POE resin, EPDM rubber, hy...

Embodiment 2

[0071] In the present embodiment, a kind of simulation plant is made of simulation composite material, and simulation composite material comprises the raw material of following weight portion: 75 parts of ethylene-vinyl acetate copolymers, 7 parts of polyethylene, 3.2 parts of talcum powder, 0.8 parts of zinc oxide powder part, 0.3 part of lubricant, 0.3 part of foaming agent, and 0.6 part of crosslinking agent.

[0072] Further, the foaming agent is azodimethylthiamine, and the crosslinking agent is di-tert-butyl peroxide.

[0073] Further, the content of vinyl acetate in the ethylene-vinyl acetate copolymer is 17wt%. The ethylene-vinyl acetate copolymer is EVA5110M. The polyethylene is polyethylene POE565.

[0074] Further, the lubricant is compounded by ethylene bis stearic acid amide and zinc stearate at a mass ratio of 1: 1.5.

[0075] Further, the simulated plant also includes 8 parts by weight of a composite synergist, and each part of the composite synergist is comp...

Embodiment 3

[0086] In the present embodiment, a kind of artificial plant is made of artificial composite material, and artificial composite material comprises the raw material of following weight portion: ethylene-vinyl acetate copolymer 91 parts, polyethylene 13 parts, talcum powder 5.2 parts, zinc oxide powder 1.2 parts parts, 0.7 parts of lubricant, 0.7 parts of foaming agent, and 1.2 parts of crosslinking agent.

[0087] Further, the foaming agent is formed by mixing azodimethylthiamine and p-toluenesulfonylhydrazide at a mass ratio of 1:0.8. The crosslinking agent is di-tert-butyl peroxide.

[0088] Further, the content of vinyl acetate in the ethylene-vinyl acetate copolymer is not more than 20wt%. The ethylene-vinyl acetate copolymer is EVA5110M. The polyethylene is polyethylene POE565.

[0089] Further, the lubricant is compounded from stearic acid and pentaerythritol stearate at a mass ratio of 1:(0.5-1.5).

[0090] Further, the simulated plant also includes 10 parts by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com