Water-based UV-curable coating, and preparation method and application method thereof

A curing coating, water-based technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of less surface modification of optical plastics, poor heat resistance of plastics, and strict requirements , to achieve excellent substrate lubrication and leveling performance, low VOC, excellent leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

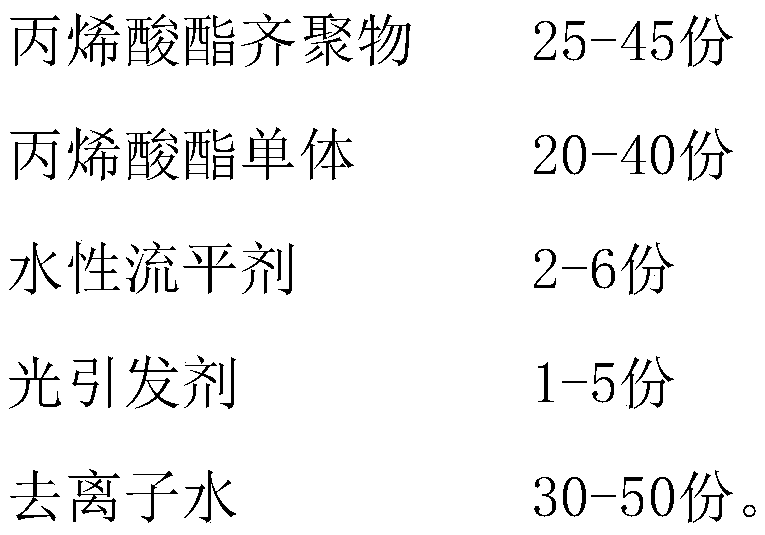

[0061] A kind of water-based UV curable paint, described water-based UV curable paint comprises the raw material of following weight portion:

[0062]

[0063]

[0064] The acrylate oligomer is composed of a hexafunctional aliphatic urethane acrylate oligomer, a four-functional aliphatic urethane acrylate oligomer and a difunctional aliphatic urethane acrylate oligomer in a weight ratio of 1.5:1:1 The mixture; the acrylate monomer is composed of isodecyl acrylate, propoxylated neopentyl glycol diacrylate, trimethylolpropane trimethacrylate and dipentaerythritol pentaacrylate in a weight ratio of 1:1.4: A mixture composed of 0.5:0.4.

[0065] The water-based leveling agent is composed of polyether-modified polydimethylsiloxane, alkyl-modified organosiloxane and polyacrylate leveling agent containing epoxy functional groups in a weight ratio of 1.4:2:1. mixture; the photoinitiator is composed of 1-hydroxycyclohexyl phenyl ketone, 2,2-dimethoxy-1,2-diphenylethanone and 2-h...

Embodiment 2

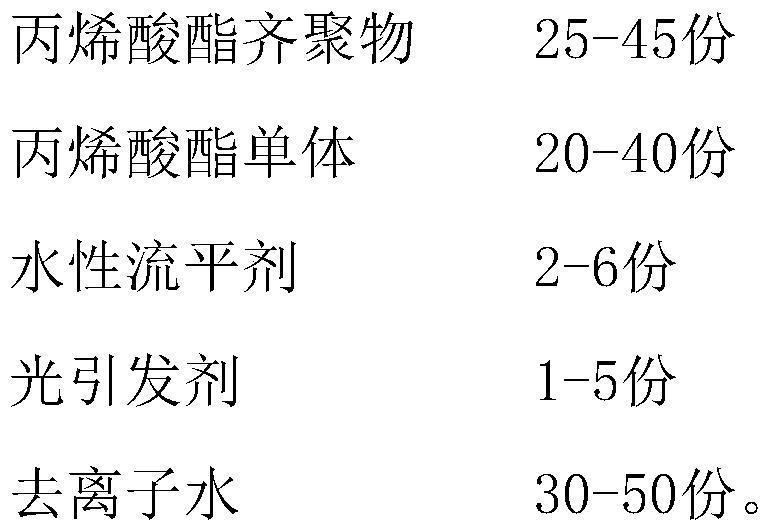

[0089] A kind of water-based UV curable paint, described water-based UV curable paint comprises the raw material of following weight portion:

[0090]

[0091]The acrylate oligomer is composed of a hexafunctional aliphatic urethane acrylate oligomer, a four-functional aliphatic urethane acrylate oligomer and a difunctional aliphatic urethane acrylate oligomer in a weight ratio of 1.8:1:1.2 The mixture; the acrylate monomer is composed of isodecyl acrylate, propoxylated neopentyl glycol diacrylate, trimethylolpropane trimethacrylate and dipentaerythritol pentaacrylate in a weight ratio of 1:1.6: 0.8: 0.5 composition mixture.

[0092] The water-based leveling agent is composed of polyether-modified polydimethylsiloxane, alkyl-modified organosiloxane and polyacrylate leveling agent containing epoxy functional groups at a weight ratio of 1.6:2.5:1 mixture; the photoinitiator is composed of 1-hydroxycyclohexyl phenyl ketone, 2,2-dimethoxy-1,2-diphenylethanone and 2-hydroxy-2-me...

Embodiment 3

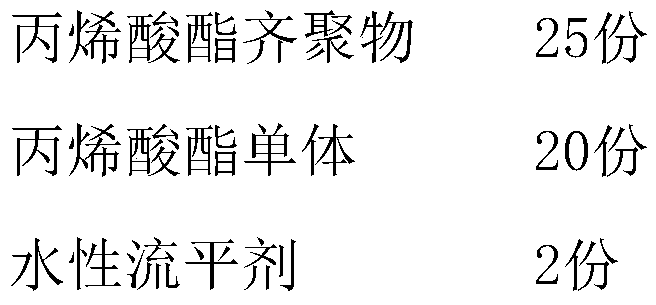

[0116] A kind of water-based UV curable paint, described water-based UV curable paint comprises the raw material of following weight portion:

[0117]

[0118] The acrylate oligomer is composed of a hexafunctional aliphatic urethane acrylate oligomer, a four-functional aliphatic urethane acrylate oligomer and a difunctional aliphatic urethane acrylate oligomer in a weight ratio of 2:1:1.5 The mixture; the acrylate monomer is composed of isodecyl acrylate, propoxylated neopentyl glycol diacrylate, trimethylolpropane trimethacrylate and dipentaerythritol pentaacrylate in a weight ratio of 1:1.8: A mixture of 1:0.6 composition.

[0119] The water-based leveling agent is composed of polyether-modified polydimethylsiloxane, alkyl-modified organosiloxane and polyacrylate leveling agent containing epoxy functional groups in a weight ratio of 1.8:3:1. mixture; the photoinitiator is composed of 1-hydroxycyclohexyl phenyl ketone, 2,2-dimethoxy-1,2-diphenylethanone and 2-hydroxy-2-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com