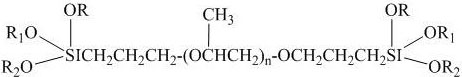

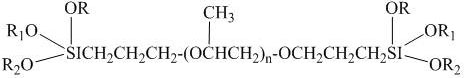

High-adhesive silane-modified polyether sealant for prefabricated buildings and preparation method thereof

A technology for silane-modified polyether and construction, applied in polyether adhesives, non-polymer adhesive additives, adhesives, etc., can solve the problems of fracture and high bonding strength, and achieve easy use and simple preparation process , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The present invention also provides a method for preparing the above-mentioned modified polyether sealant for prefabricated buildings with high adhesiveness, which is characterized in that it comprises the following steps:

[0066] Prepare component A and component B, and the sequence of preparing component A and component B is not limited;

[0067] The preparation method of component A is: add nano-calcium carbonate, heavy calcium carbonate, and amino-terminated polyether into the reaction kettle, blend for 1 to 2 hours under vacuum conditions, and then add silane-modified polyether polymer, Combined agent I, vinyltrimethoxysilane, thixotropic agent and anti-aging agent, blended under vacuum for 0.5~1 hour to obtain component A;

[0068] The preparation method of component B is: add epoxy resin, flexible diluent, coupling agent II, and catalyst into the reaction kettle, and blend under vacuum conditions for 1 to 2 hours to obtain a modified primer-free prefabricated bu...

Embodiment 1

[0072] Dehydrate and blend 5 parts of amino-terminated polyether T-3000, 20 parts of nano-calcium carbonate, and 30 parts of heavy calcium carbonate in a vacuum state for 1 hour, then add 50 parts of silane-modified polyether polymer 201S, 3 parts γ-Aminopropyltrimethoxysilane, 5 parts hydrogenated castor oil, 1 part amine light stabilizer RIASORB UV-770 and 1 part phenolic antioxidant RIANOX 245 and 1 part vinyltrimethoxysilane mixture, vacuum Dehydration and blending at lower temperature for 0.5 hours, to obtain component A of weather-resistant sealant for prefabricated concrete joints; 15 parts of epoxy resin E-44SMF6101, 5 parts of polyethylene glycol diglycidyl ether, 3 parts of 3-(2,3 -Glycidoxy)propyltrimethoxysilane, 2 parts of chelated tin and 1 part of DMP-30 mixed catalyst were blended under vacuum protection for 1 hour to obtain component B of weather-resistant sealant for prefabricated concrete joints. Mix A component and B component according to the mass ratio of...

Embodiment 2

[0074] Dehydrate and blend 5 parts of amino-terminated polyether D-2000, 20 parts of nano-calcium carbonate, and 10 parts of heavy calcium carbonate in a vacuum state for 2 hours, then add 40 parts of silane-modified polyether polymer 201S, 3 parts γ-Aminopropyltriethoxysilane, 4 parts of polyamide wax, 0.5 part of amine light stabilizer RIASORB UV-770 and 0.5 part of phenolic antioxidant RIANOX 245 and 1 part of vinyl triethoxysilane mixture, Dehydration and blending in a vacuum state for 0.7 hours to obtain component A of the weather-resistant sealant for prefabricated concrete joints; 10 parts of epoxy resin SMF170, 2 parts of polypropylene glycol diglycidyl ether, 2 parts of 2-(3,4- Oxycyclohexyl)ethyltriethoxysilane, 1 part of organic titanium compound and 1 part of DMP-30 mixture were blended for 1 hour under vacuum protection to obtain component B of weather-resistant sealant for prefabricated concrete joints. Mix A component and B component according to the mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com