Testing device and method capable of testing desulphurization and denitration performances of reactive coke simultaneously

A technology of desulfurization and denitrification and test equipment, which is applied in the direction of measuring equipment, instruments, scientific instruments, etc., can solve the problems of multi-time, detection, and inability to perform active coke desulfurization performance, and achieve the effect of shortening test time and accurate characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

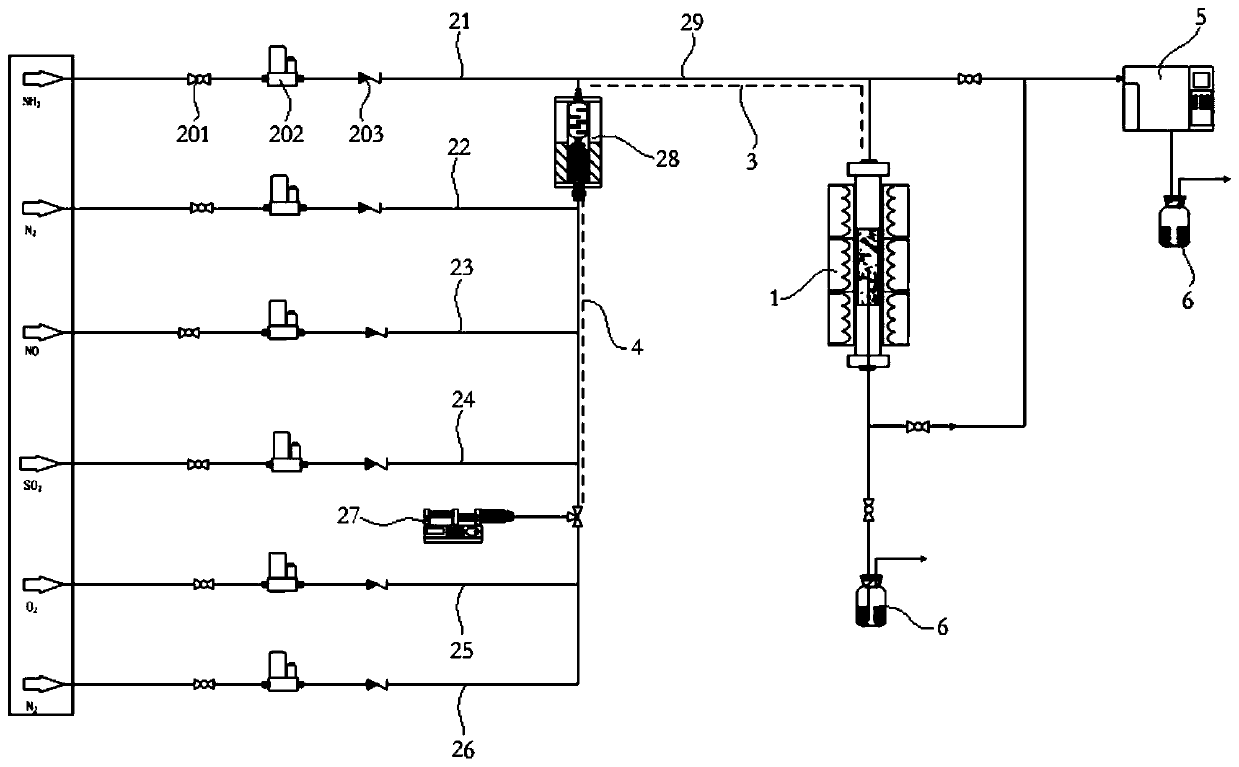

[0031] Such as figure 1 , an embodiment of the present invention provides a test device capable of simultaneously testing desulfurization and denitrification performance of activated coke, including a test gas configuration system, a desulfurization and denitrification reactor 1, and a gas component detection system 5. The test gas configuration system includes an ammonia gas supply pipe Road 21, the first nitrogen supply pipeline 22, NO supply pipeline 23, SO 2 Supply pipeline 24 and oxygen supply pipeline 25, described test gas configuration system also comprises gas mixer 28 and the water vapor supply mechanism that mixes water vapor in described gas mixer 28, described first nitrogen supply pipeline 22 , the NO supply pipeline 23, the SO 2 Both the supply pipeline 24 and the oxygen supply pipeline 25 are connected to the air inlet of the gas mixer 28, and the gas mixer 28 is connected to the desulfurization and denitrification reactor 1 through a gas mixture pipeline 29, ...

Embodiment 2

[0049] The embodiment of the present invention also relates to a method for testing the desulfurization and denitrification performance of activated coke by using the above test device, including:

[0050] Load the active coke into the desulfurization and denitration reactor 1, and set the working temperature of the desulfurization and denitration reactor 1 to 130-170°C;

[0051] The first nitrogen supply pipeline 22, the NO supply pipeline 23, the SO 2 The supply pipeline 24 and the oxygen supply pipeline 25 start to supply gas according to the set flow rate, and at the same time set the working temperature of the rear pipeline heating unit 3 to 120-150°C; observe the desulfurization and denitrification reactor 1 through the gas component detection system 5 The concentration of each component in the mixed gas at the inlet side reaches the preset value until it becomes stable;

[0052] Mix water vapor into the gas mixer 28 through the water vapor supply mechanism, so that the...

Embodiment 3

[0061] The embodiment of the present invention also relates to a method for testing the desulfurization and denitrification performance of activated coke by using the above test device, including:

[0062] S1, loading active coke into the desulfurization and denitrification reactor 1;

[0063] S2, the desulfurization and denitrification reaction-activated coke regeneration reaction treatment process is carried out N times in a cycle, and N is greater than 1; wherein, the desulfurization and denitrification reaction is carried out by the method provided in the above-mentioned embodiment 2, and the specific treatment process is not repeated here;

[0064] The active coke regeneration reaction includes: feeding nitrogen gas into the desulfurization and denitrification reactor 1, making the desulfurization and denitration reactor 1 work at the active coke regeneration reaction temperature until the regeneration is completed;

[0065] S3, Fetch recorded SO 2 and nitrogen oxide gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com