Dual-light emitting layer structure blue-light OLED and manufacturing process thereof

A technology of manufacturing process and light-emitting layer, which is applied in the field of blue light OLED, and achieves the effects of good feasibility and repeatability, simple manufacturing process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

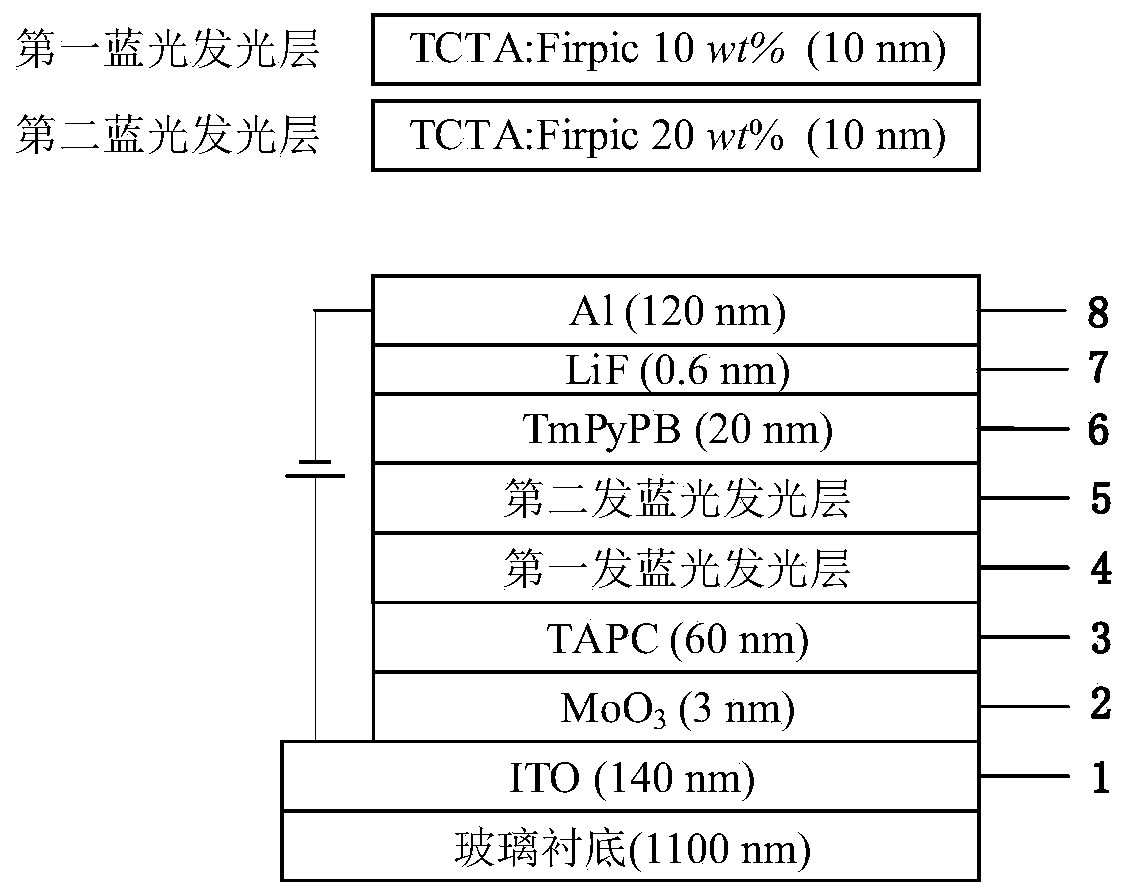

preparation example Construction

[0036] (2) Preparation of hole injection layer

[0037] Put the processed ITO glass substrate into the ultra-high vacuum vacuum evaporation chamber to prepare various functional layers, MoO 3 The evaporation rate is controlled at 0.3 Angstroms per second, and the duration is about 100 seconds;

[0038] (3) Preparation of hole transport layer and electron blocking layer

[0039] The hole injection material TAPC is heated to the evaporation temperature, the evaporation rate is controlled at 1 Angstrom per second, and the evaporation time is about 600 seconds;

[0040] (4) Preparation of double light-emitting layers

[0041] Co-evaporation of host and guest materials is required when evaporating the light-emitting layer. The guest doping concentration and thickness of the light-emitting layer of the first blue light-emitting layer and the second blue light-emitting layer must satisfy the relationship of y≤0.5x, 5≤w≤30. In this example, the evaporation rate of TCTA in the first...

Embodiment 2

[0046] Embodiment 2 (comparative example):

[0047] Compared with the device of the invention, this comparative example has only one light-emitting layer, the doping concentration of the guest is the same as that of the first light-emitting layer of the device of the invention, and the thickness of the light-emitting layer is 2w, that is, 20. The rest of the structure is exactly the same. The comparison device structure is:

[0048] Comparative example device: Glass(1100nm) / ITO(140nm) / MoO 3 (3nm) / TAPC(60nm) / TCTA: Firpic(10%,20nm) / TmPyPB(20nm) / LiF(0.6nm) / Al(120nm);

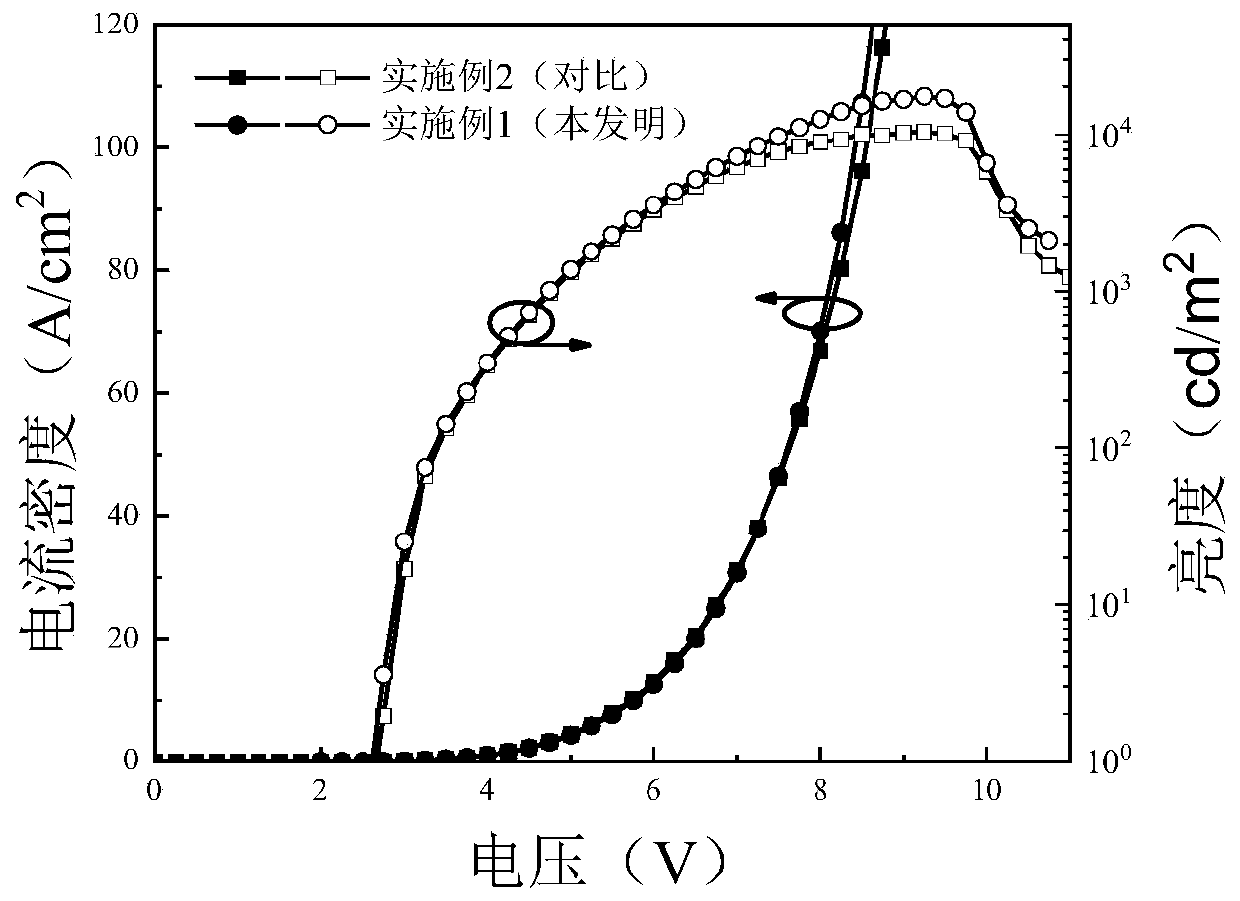

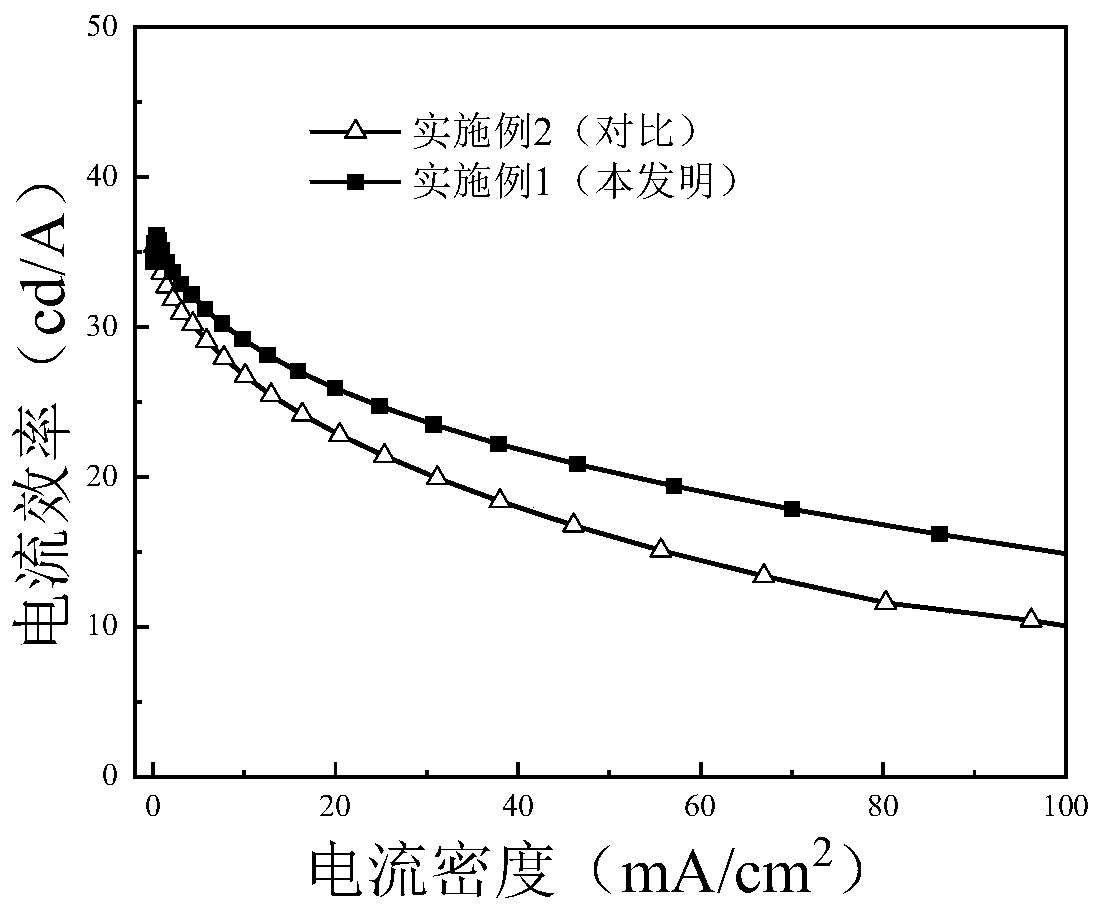

[0049] The comparison of performance parameters between the device embodiment 1 of the present invention and the comparative device embodiment 2 is shown in the table below.

[0050]

[0051] From the above data, it can be found that the light-up voltage and driving voltage of the device of the present invention (Example 1) are slightly lower than that of the comparative device (Example 2), and the maximum ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com