Method for preparing carbon nano-cage by catalyzing organic ligand by metal ion, prepared carbon nano-cage and application of carbon nano-cage

A technology of carbon nanocages and metal ions, which is applied in the preparation and application of nanomaterials, can solve the problems of different shapes and sizes, limit the chemical activity of carbon materials, and the high cost of carbon nanocages, so as to achieve efficient production and use, excellent Electrochemical performance, the effect of large market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

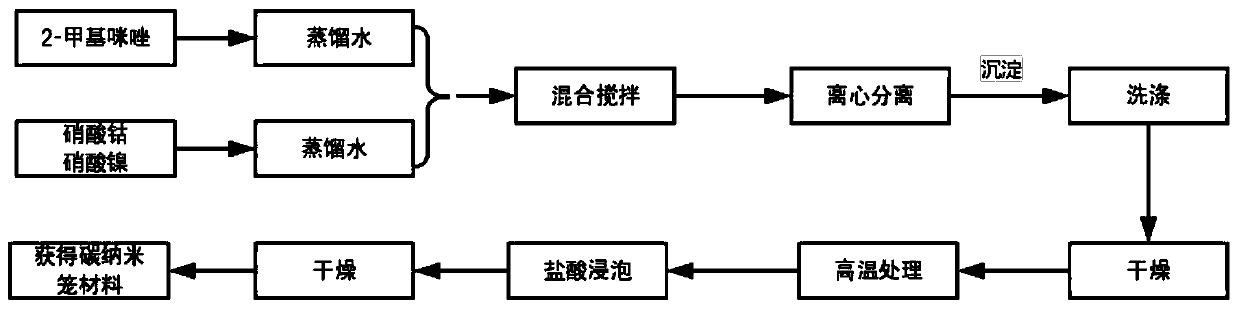

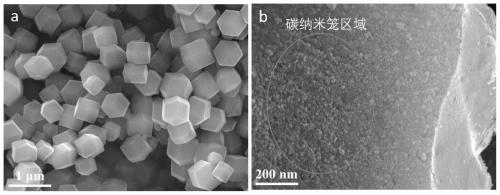

[0042] Such as figure 1 As shown, a method for preparing carbon nanocages with metal ion-catalyzed organic ligands in this embodiment, the method specifically includes the following steps: first dissolve 3.7g 2-methylimidazole in 80mL aqueous solution, and magnetically stir for 30min to form Uniform A solution, while 1.23g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) and 0.34g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) Dissolve in 80mL aqueous solution and stir magnetically for 30min to form a uniform B solution. Slowly pour solution B into solution A, react at room temperature for 12 hours, and form a purple precipitate, which is obtained by a high-speed centrifuge at 8000rpm / min, and the product is washed and dried repeatedly with distilled water to obtain a regular shape with a size of about 500nm metal organic framework precursors. Put the pretreated powder (metal-organic framework precursor) in a porcelain boat and place it in a high-temperature furnace, first heat it to 400°C f...

Embodiment 2

[0048] A method of preparing carbon nanocages by using metal ions to catalyze organic ligands in this example, the steps are basically the same as those in this example, the only difference is that the heat treatment step of the metal organic framework precursor in this example is: first heating to 400°C Calcined at constant temperature for 2 hours, then continued to heat up to 800°C for 2 hours, and the rest of the conditions were exactly the same.

Embodiment 3

[0050] In this example, a method for preparing carbon nanocages by using metal ions to catalyze organic ligands, the steps are basically the same as those in the examples, the only difference being that the high-temperature treatment step of the metal-organic framework precursor is: first heating to 400°C and calcination at a constant temperature for 2 hours , and then continue to heat up to 1000°C for calcination at a constant temperature for 2 hours, and the rest of the conditions are exactly the same.

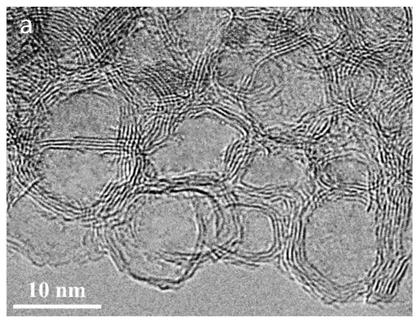

[0051] Carry out XRD test respectively with the carbon nanocage material that embodiment 1-3 obtains through different high temperature heat treatments, test result is as follows Figure 4 shown. Further analysis of the chemical composition of the material found that strong characteristic peaks in XRD correspond to the positions in the standard card of nickel and cobalt, indicating that the material contains a certain amount of cobalt and nickel metal elements, and the cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com