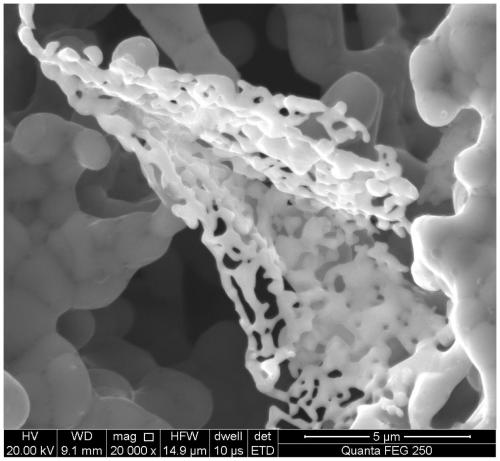

Hierarchical pore structure nickel base alloy and its preparation method and application

A nickel-based alloy and multi-level pore technology, applied in the field of porous metal materials, can solve the problems of reduced electrode activity, limitation, and inability to discharge hydrogen in time, and achieve the effect of easy implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Add 1.5g of gelatin and 50g of water into the mixing bottle. After the gelatin is completely dissolved, add 80g of nickel powder and 5g of aluminum powder into the mixing tank. After ball milling and mixing for 12 hours, a uniform water-based slurry containing nickel and aluminum is obtained; Inject the slurry into a mold with a copper bottom, put it on the copper substrate connected to the freezing device at the bottom, set the temperature at the lower end of the cold field to -20°C, and the temperature at the upper end to -20°C, and move the green body to a freeze dryer after it is completely frozen. ice crystals. After drying, transfer the green body to a hydrogen furnace for sintering, heat at a rate of 5 °C / min to 350 °C for 2 hours, and remove the added binder; further increase the rate of 5 °C / min to 1000 °C for 2 hours , and the samples were taken out after the furnace was cooled to room temperature. Soak the porous sample in 20% NaOH solution and corrode for 5 ...

Embodiment 2

[0039] Add 80g of deionized water, 4g of polyvinyl alcohol, and 0.24g of xanthan gum into the mixing bottle. After the organic matter is completely dissolved, add 80g of nickel powder, 50g of copper powder, and 10g of aluminum powder into the ball mill tank, and after ball milling for 12 hours, Obtain a uniform water-based nickel-copper-aluminum slurry; inject the slurry into a square plastic mold with copper at the bottom, put it on the copper substrate connected to the freezer at the lower end, set the temperature at the lower end of the cold field to -30°C, and the temperature at the upper end to 5°C. After the green body is completely frozen, it is moved to a freeze dryer to remove ice crystals. After drying, the green body was transferred to a hydrogen furnace for sintering, heated to 400°C at a rate of 5°C / min and kept for 2 hours to remove the added binder and thickener; further increased to 950°C at a rate of 10°C / min ℃ for 2 hours, and the samples were taken out after...

Embodiment 3

[0041] Add 100g of deionized water and 1.5g of gelatin into the mixing bottle, after the gelatin is completely dissolved, add 50g of NiO powder, 10g of MoO 3 Al powder, 10g of Al powder ball milled and mixed for 20 hours to obtain a uniform water-based slurry; inject the slurry into a square plastic mold with a copper bottom, put it on the copper substrate connected to the freezer at the bottom, and set the temperature at the bottom of the cold field to -50°C , the temperature at the upper end is -5°C. After the green body is completely frozen, move it to a freeze dryer to remove ice crystals. After drying, transfer the green body to a hydrogen furnace for sintering, heat at a rate of 2 °C / min to 350 °C for 2 hours, and remove the added binder; further increase the rate of 5 °C / min to 1050 °C for 2 hours , and the samples were taken out after the furnace was cooled to room temperature. Soak the porous sample in 20% NaOH solution and corrode for 5 hours to obtain a porous nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com