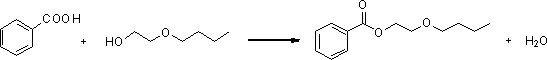

Ethylene glycol monobutyl ether benzoate and preparation method thereof

A technology of ethylene glycol monobutyl ether and benzoic acid is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as low boiling point, high cost, peculiar smell, etc. Low cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 1 mol of benzoic acid, 2 mol of ethylene glycol monobutyl ether, and 0.02 mol of concentrated sulfuric acid in a 1000 mL round bottom flask. The temperature was raised to 170°C for condensing and reflux reaction for 6 hours, and after the reaction was completed, it was cooled to room temperature, and the conversion rate of benzoic acid was 85.5% as tested by gas chromatography.

[0034] The reacted material is rectified in the rectification tower, and the pressure in the tower is about -0.095MPa. The top temperatures of the four towers are 42°C, 91°C, 125°C, and 180°C in sequence. The final product has a purity of 99.72% and no peculiar smell.

Embodiment 2

[0036] Add 1 mol of benzoic acid, 5 mol of ethylene glycol monobutyl ether, and 0.05 mol of p-toluenesulfonic acid in a 1000 mL round bottom flask. Raise the temperature to 170°C to condense and reflux for 12 hours. After the reaction, cool to room temperature. The conversion rate of benzoic acid is 96.5% as tested by gas chromatography.

[0037] The reacted material is rectified in the rectification tower, and the pressure in the tower is about -0.095MPa. The top temperatures of the four towers are 42°C, 90°C, 128°C, and 178°C in sequence. The final product has a purity of 99.85% and no peculiar smell.

Embodiment 3

[0039] 1 mol of benzoic acid, 3 mol of ethylene glycol monobutyl ether, and 0.001 mol of tetrabutyl titanate were successively added into a 1000 mL round bottom flask. The temperature was raised to 150°C for condensing and reflux reaction for 4 hours, and after the reaction was completed, it was cooled to room temperature, and the conversion rate of ethylene glycol monobutyl ether was 92.3% as tested by gas chromatography.

[0040] The reacted material is rectified in the rectification tower, and the pressure in the tower is about -0.090MPa. The top temperatures of the four towers are 45°C, 100°C, 130°C, and 180°C in sequence. The final product has a purity of 99.65% and no peculiar smell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com