Method for preparing diene rubber latex with large grain diameter

A technology of diene rubber and large particle size, which is applied in the field of polymer preparation and can solve problems such as equipment corrosion and increased COD in wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

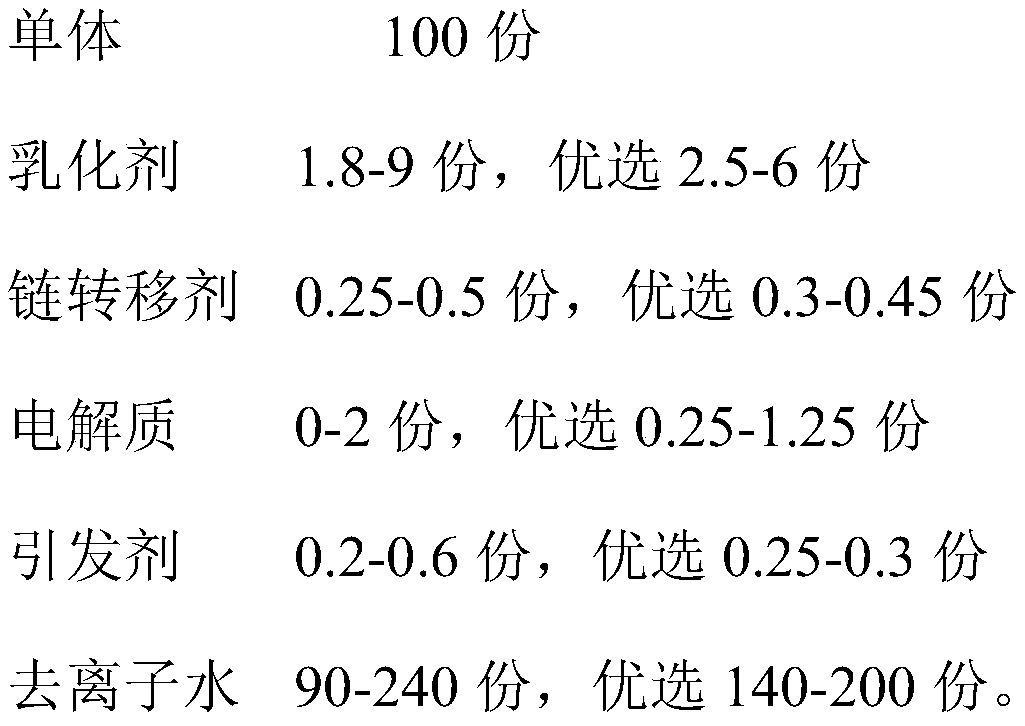

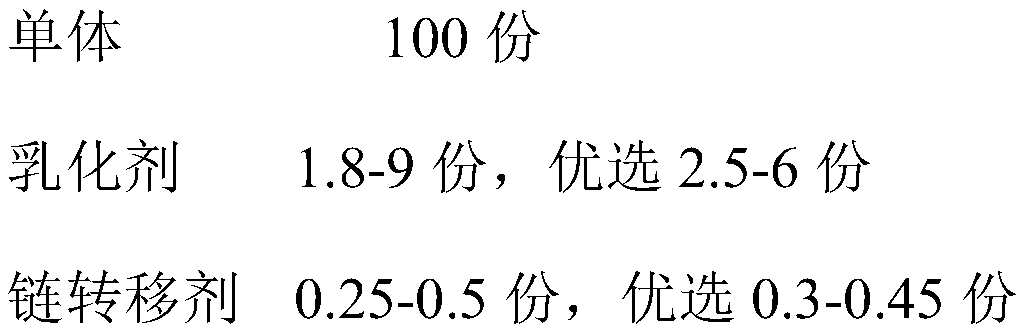

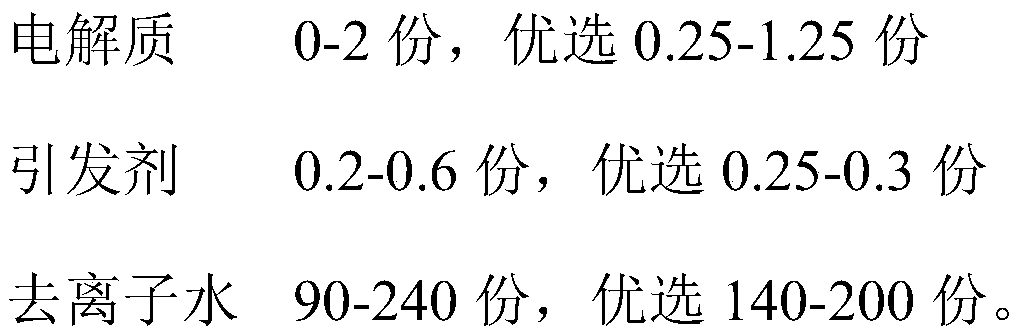

Method used

Image

Examples

Embodiment 1

[0036] 1) Polymerization: Take 95 parts of butadiene, 5 parts of styrene, 1.3 parts of potassium oleate, 1.1 parts of potassium abietate,

[0037] 2.4 parts of 1,18-octadec-9-ene-dioic acid monopotassium salt, 0.45 parts of tert-dodecyl mercaptan, 0.3 parts of potassium persulfate, 0.36 parts of potassium bicarbonate, 0.24 parts of sodium pyrophosphate, deionized 145 parts of water was added into the reactor, the initial pH was about 10.5, and the polymerization reaction was carried out at 67°C. The reaction time was 11 hours, the conversion rate was 97%, and the polymerization reaction was completed. Small particle size latex particle size 100nm.

[0038] 2) Agglomeration: adding KOH solution to the above polybutadiene latex to pH 12.5, and stirring to obtain latex with large particle size.

[0039] 3) Products:

[0040] Particle size: 300nm.

Embodiment 2

[0042]1) Polymerization: Take 95 parts of butadiene, 5 parts of isoprene, 0.62 parts of potassium oleate, 0.72 parts of potassium abietate, 0.1 part of sodium lauryl sulfate, and monopotassium 1,18-octadecanedioate Add 0.36 parts of salt, 0.25 parts of tert-dodecyl mercaptan, 0.6 parts of potassium persulfate, 0.6 parts of potassium bicarbonate, 0.25 parts of potassium sulfate, 0.4 parts of potassium carbonate, and 90 parts of deionized water into the reaction kettle, and the initial pH About 11, the polymerization reaction was carried out at 65°C. The reaction time was 15 hours, the conversion rate was 91%, and the polymerization reaction was completed. Small particle size latex particle size 150nm.

[0043] 2) Agglomeration: adding KOH solution to the above polybutadiene latex until the pH is 14, stirring to obtain latex with large particle size.

[0044] 3) Products:

[0045] Particle size: 500nm.

Embodiment 3

[0047] 1) Polymerization: Take 95 parts of butadiene, 5 parts of styrene, 0.3 parts of potassium oleate, 0.6 parts of potassium abietate, 8.1 parts of monopotassium 1,12-dodecanedioic acid, tert-dodecyl mercaptan 0.3 parts, 0.3 parts of potassium persulfate, and 140 parts of deionized water were added into the reaction kettle, the initial pH was about 9, and the polymerization reaction was carried out at 67°C. The reaction time was 8 hours, and when the conversion rate was 96%, the polymerization reaction was completed. Small particle size latex particle size 70nm.

[0048] 2) Agglomeration: adding KOH solution to the above polybutadiene latex to pH 11.6, stirring to obtain latex with large particle size.

[0049] 3) Products:

[0050] Particle size: 200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com