Strong-effect antibacterial wear-resistant brush wire and preparation method thereof

A brush filament and antibacterial agent technology, which is applied in the field of strong antibacterial and wear-resistant brush filament and its preparation, can solve the problems of easy deformation and damage of plant fibers, easy wear and accumulation of bacteria, and high price of animal hair, so as to improve stability and antibacterial properties, enhance wear resistance, improve toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

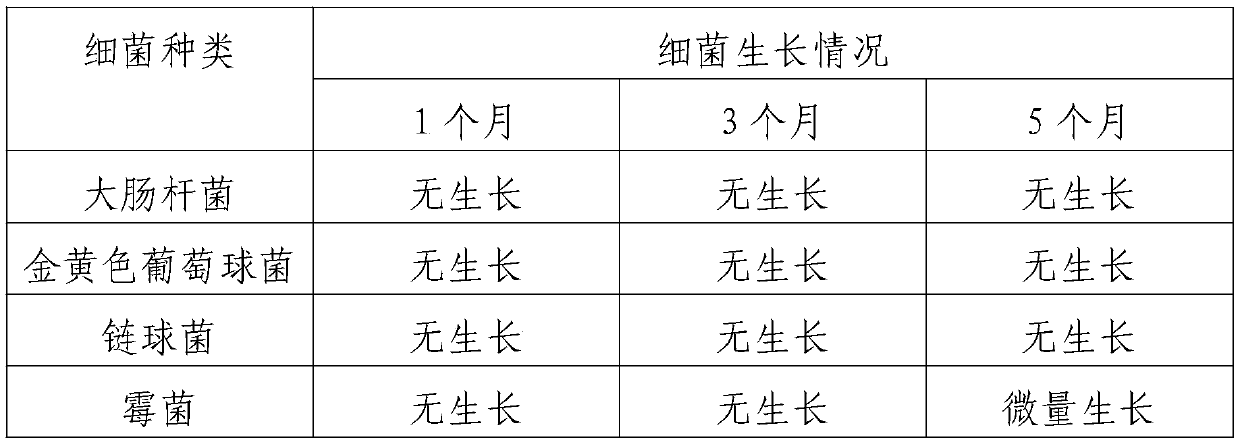

Examples

Embodiment 1

[0024] A powerful antibacterial and wear-resistant brush filament, which is made of the following raw materials in parts by weight: 18 parts of polypropylene resin, 12 parts of phenolic resin, 8 parts of low-density polyethylene resin, trimesene 2 parts of formic acid, 1 part of activated alumina, 1 part of shell activated carbon, 2 parts of nano-titanium dioxide, 2 parts of N, N-dimethylacetamide, 2 parts of ethylenediaminetetraacetic acid, 1 part of glass fiber, 2 parts of stilbite , 2 parts of antibacterial agent, 1 part of toughening agent, 2 parts of crosslinking agent.

[0025] The antibacterial agent is a mixture of ethyl vanillin, lithium carbonate, ammonium dihydrogen phosphate, silver hydrogen peroxide ion, and hydroxyethylene diphosphonic acid in a mass ratio of 1:2:1:1:2; the toughening agent It is a mixture of polysulfide rubber, polyvinyl butyral, polyphenylene ether ketone and neoprene in a mass ratio of 2:1:1:1; the crosslinking agent is n-butyl titanate, dicum...

Embodiment 2

[0033] A powerful antibacterial and wear-resistant brush filament, which is made of the following raw materials in parts by weight: 22 parts of polypropylene resin, 16 parts of phenolic resin, 10 parts of low-density polyethylene resin, trimesene 3 parts of formic acid, 2 parts of activated alumina, 3 parts of shell activated carbon, 4 parts of nano-titanium dioxide, 3 parts of N,N-dimethylacetamide, 3 parts of ethylenediaminetetraacetic acid, 3 parts of glass fiber, 3 parts of stilbite , 3 parts of antibacterial agent, 2 parts of toughening agent, 3 parts of crosslinking agent.

[0034] The antibacterial agent is a mixture of ethyl vanillin, lithium carbonate, ammonium dihydrogen phosphate, silver hydrogen peroxide ion, and hydroxyethylene diphosphonic acid in a mass ratio of 1:2:1:1:2; the toughening agent It is a mixture of polysulfide rubber, polyvinyl butyral, polyphenylene ether ketone and neoprene in a mass ratio of 2:1:1:1; the crosslinking agent is n-butyl titanate, d...

Embodiment 3

[0042] A powerful antibacterial and wear-resistant brush filament, which is made of the following raw materials in parts by weight: 20 parts of polypropylene resin, 14 parts of phenolic resin, 9 parts of low-density polyethylene resin, trimesene 2.5 parts of formic acid, 1.5 parts of activated alumina, 2 parts of shell activated carbon, 3 parts of nano-titanium dioxide, 2.5 parts of N,N-dimethylacetamide, 2.5 parts of ethylenediaminetetraacetic acid, 2 parts of glass fiber, 2.5 parts of stilbite , 2.5 parts of antibacterial agent, 1.5 parts of toughening agent, 2.5 parts of crosslinking agent.

[0043] The antibacterial agent is a mixture of ethyl vanillin, lithium carbonate, ammonium dihydrogen phosphate, silver hydrogen peroxide ion, and hydroxyethylene diphosphonic acid in a mass ratio of 1:2:1:1:2; the toughening agent It is a mixture of polysulfide rubber, polyvinyl butyral, polyphenylene ether ketone and neoprene in a mass ratio of 2:1:1:1; the crosslinking agent is n-bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com