Method for preparing indium-aluminum-zinc oxide thin film transistor in low temperature environment

A technology of oxide film and low-temperature environment, which is applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of long thermal annealing time, reduce device production efficiency, limit the application of flexible transparent circuits, etc., and achieve strong repeatability , excellent electrical properties, and the effect of shortening the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

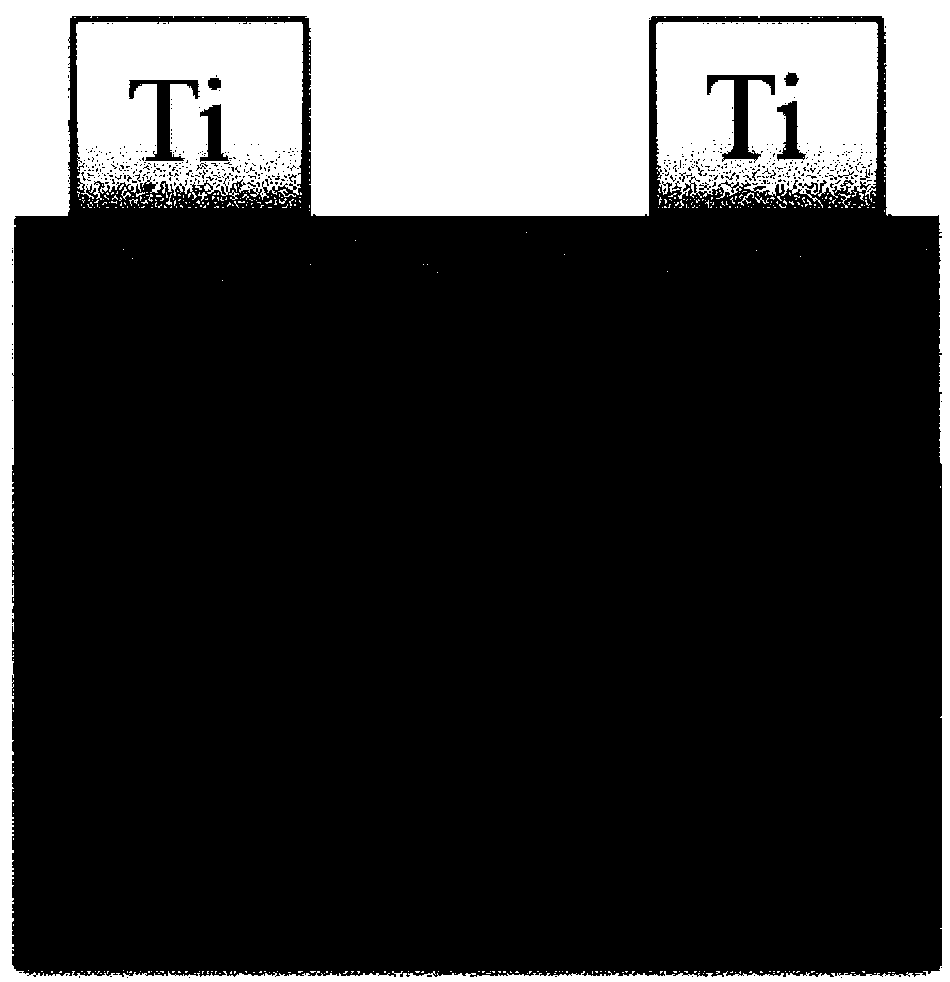

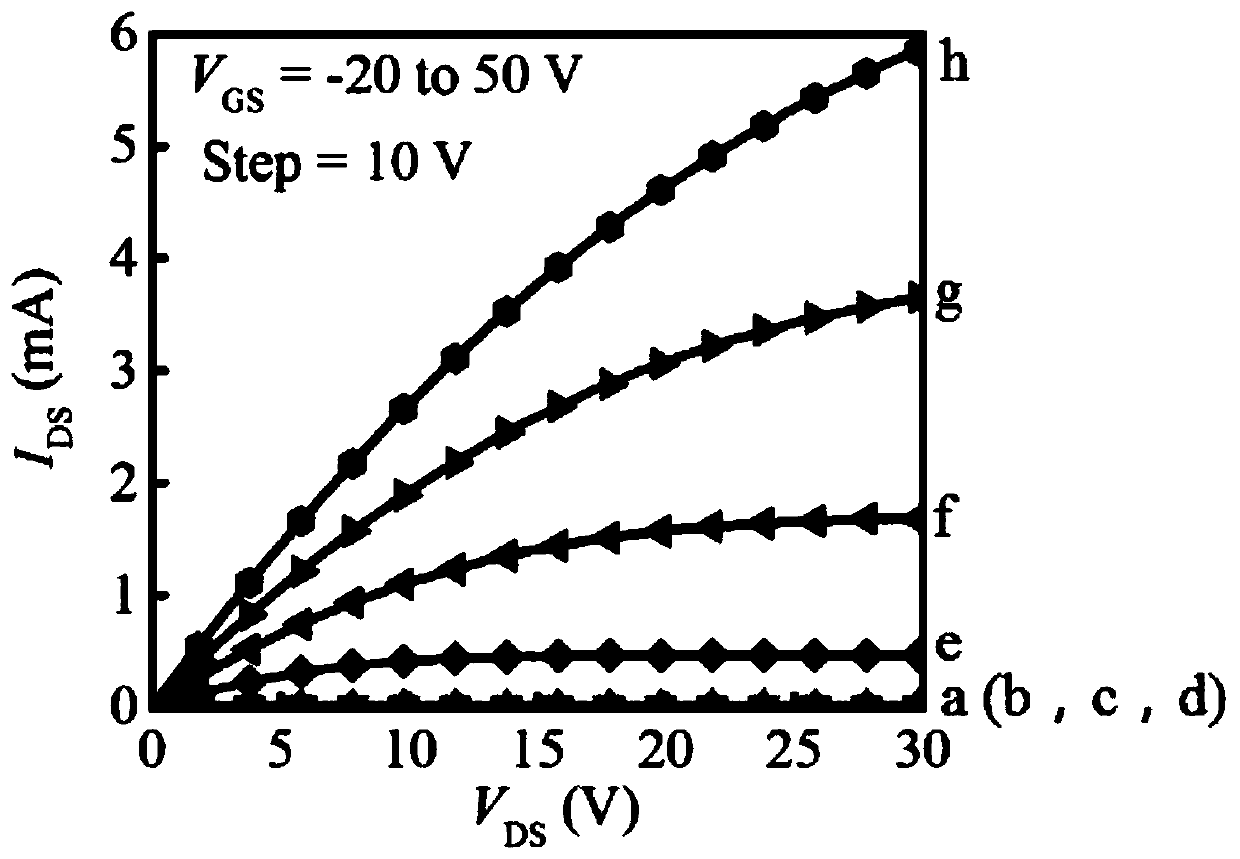

[0054] A method for preparing indium aluminum zinc oxide thin film transistors in a low temperature environment. A multi-element amorphous metal oxide thin film transistor includes a substrate, an IAZO active layer, a source electrode and a drain electrode, and a source electrode and a drain electrode from bottom to top. Grown on IAZO active layer, such as figure 2 As shown, the preparation method is carried out at a temperature of 20°C-70°C, and includes the following steps:

[0055] (1) Growing an IAZO film on a substrate to prepare the IAZO active layer;

[0056] (2) Turn on the UV-ozone power switch to make the UV-ozone work 3-5 minutes in advance; ensure that the UV-ozone chamber is relatively clean; the UV-ozone model is ProCleaner TM 220.

[0057] (3) Place the sample generated in step (1) in UV-ozone, the processing time is 3 minutes;

[0058] (4) Source and drain electrodes are grown on the surface of the IAZO active layer to obtain.

[0059] UV-ozone is a low-temperature tr...

Embodiment 2

[0061] According to the method of preparing an indium aluminum zinc oxide thin film transistor in a low temperature environment according to embodiment 1, the difference is that:

[0062] In step (1), the IAZO thin film is grown on the substrate by the radio frequency magnetron sputtering method to obtain the IAZO active layer, including the following steps:

[0063] A. Open the door of the RF magnetron sputtering chamber, put in the substrate and IAZO ceramic target, and close the chamber door;

[0064] B. Vacuum until the vacuum degree in the chamber is lower than 1×10 -5 Torr;

[0065] C. Pour high-purity Ar into the chamber, stop charging after 1 minute, and repeat this operation 3 times;

[0066] D. Set the sputtering power to 90W, pass in high-purity Ar, adjust the gas flow rate to 20SCCM, and keep the indoor working pressure at 3.68mTorr;

[0067] E. Sputtering for 13 minutes and 20 seconds, turn off the sputtering power supply;

[0068] F. After waiting for 30 minutes, take out th...

Embodiment 3

[0082] According to the method of preparing an indium aluminum zinc oxide thin film transistor in a low temperature environment according to embodiment 1, the difference is that:

[0083] In step (3), the processing time is 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

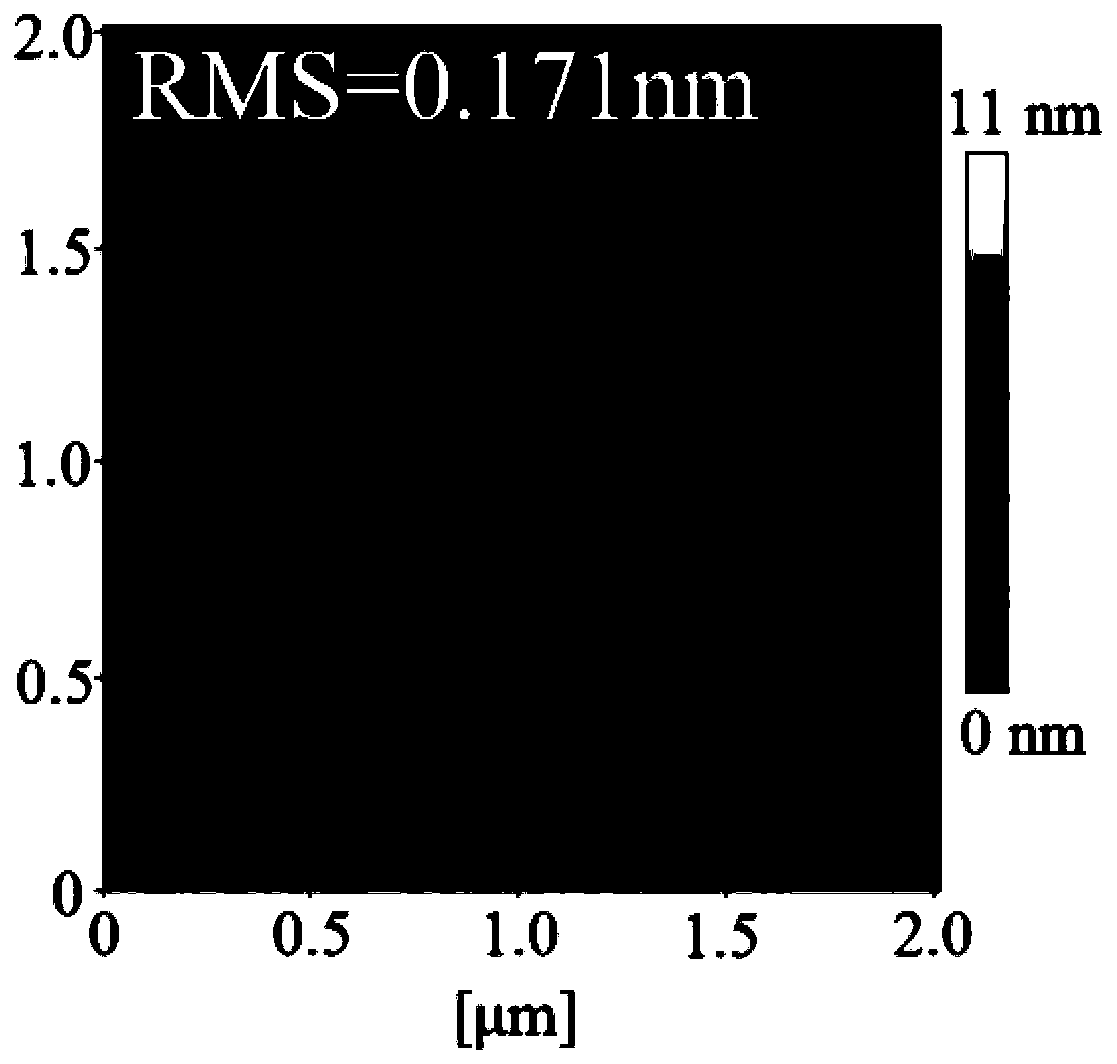

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com