Polyacrylamide nano microsphere profile control agent for oilfield chemical oil recovery

A polyacrylamide and chemical oil recovery technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low temperature resistance, poor salt resistance, etc., and achieve large particle size, good salt resistance, Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

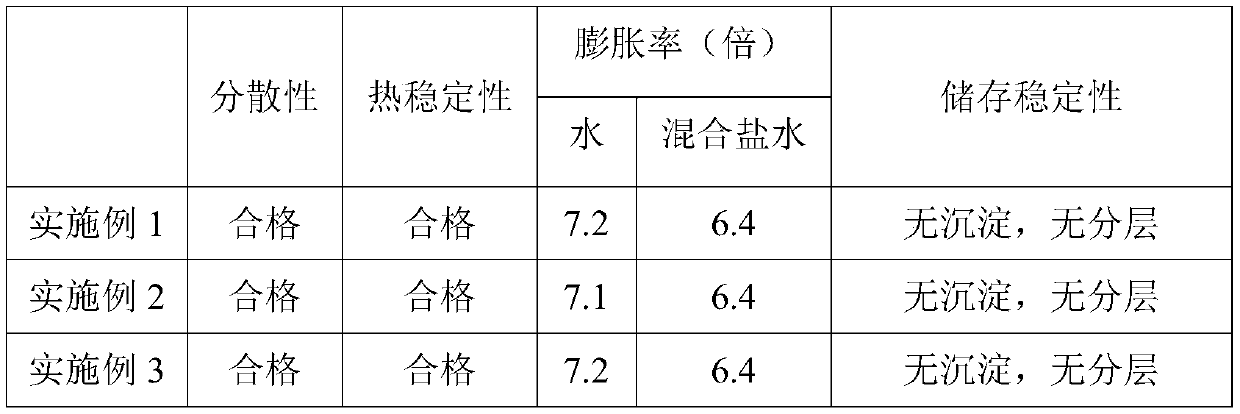

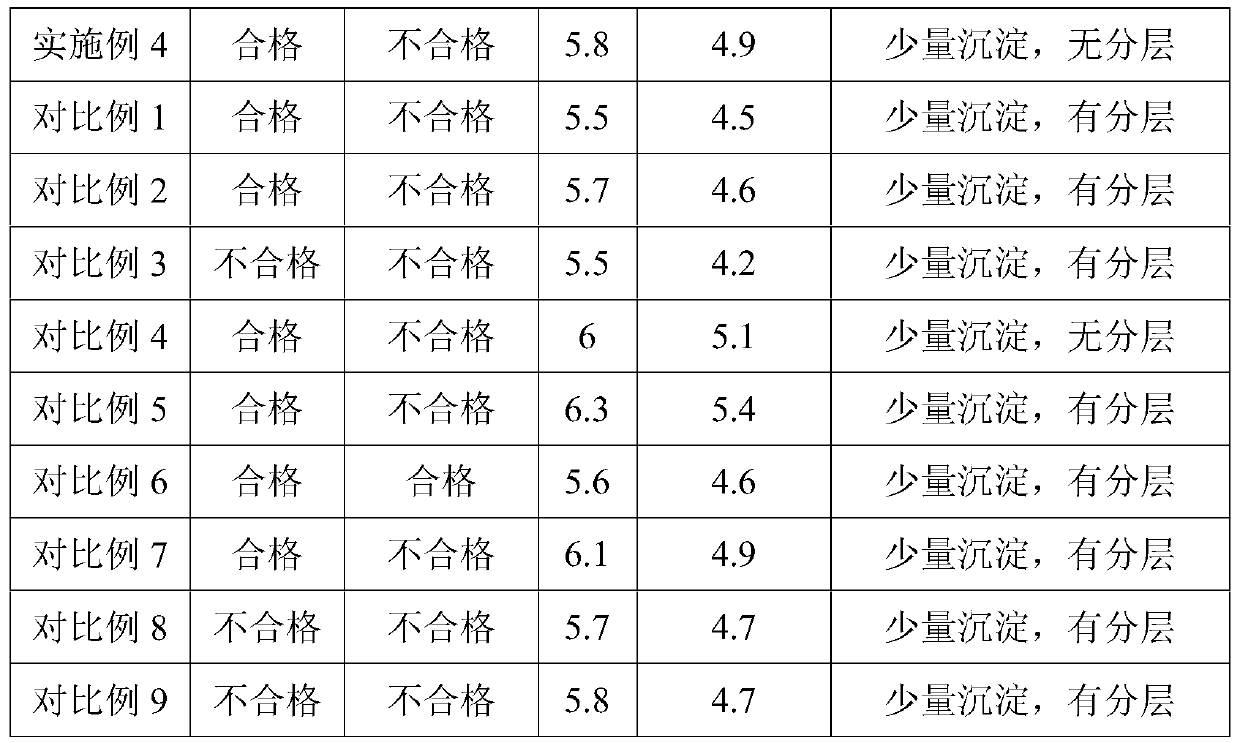

Examples

Embodiment 1

[0061] Polyacrylamide nano-microsphere profile control agent for chemical oil recovery in oil field, including the following raw materials in parts by weight: 15 parts of active auxiliary agent, 22 parts of reaction monomer, 43 parts of oil phase medium, 3 parts of crosslinking agent, 0.03 parts of initiator part, co-initiator 0.015 part, water 18 parts.

[0062] The reaction monomer is obtained by mixing acrylic acid, 2-acrylamide-2-methylpropanesulfonate and 2-vinyl-1,1-cyclopropanedicarboxamide; the acrylic acid, 2-acrylamide- The molar ratio of sodium 2-methylpropanesulfonate and 2-vinyl-1,1-cyclopropanedicarboxamide is 1:0.65:0.2.

[0063] The coagent is obtained by mixing sorbitan monooleate, sorbitan monooleate polyoxyethylene ether, polyethylene glycol laurate, and ammonium substances. The sorbitan monooleate The weight ratio of acid ester, sorbitan monooleate polyoxyethylene ether, polyethylene glycol laurate and ammonium substances is 1:0.6:0.8:0.35.

[0064] The r...

Embodiment 2

[0072] Polyacrylamide nano-microsphere profile control agent for chemical oil recovery in oil field, including the following raw materials in parts by weight: 14 parts of active auxiliary agent, 20 parts of reaction monomer, 40 parts of oil phase medium, 2 parts of crosslinking agent, 0.02 parts of initiator part, 0.01 part of co-initiator, and 15 parts of water.

[0073] The reaction monomer is obtained by mixing acrylic acid, 2-acrylamide-2-methylpropanesulfonate and 2-vinyl-1,1-cyclopropanedicarboxamide; the acrylic acid, 2-acrylamide- The molar ratio of sodium 2-methylpropanesulfonate and 2-vinyl-1,1-cyclopropanedicarboxamide is 1:0.65:0.2.

[0074] The coagent is obtained by mixing sorbitan monooleate, sorbitan monooleate polyoxyethylene ether, polyethylene glycol laurate, and ammonium substances. The sorbitan monooleate The weight ratio of acid ester, sorbitan monooleate polyoxyethylene ether, polyethylene glycol laurate and ammonium substances is 1:0.6:0.8:0.35.

[00...

Embodiment 3

[0083] Polyacrylamide nano-microsphere profile control agent for chemical oil recovery in oil field, including the following raw materials in parts by weight: 16 parts of active auxiliary agent, 23 parts of reaction monomer, 46 parts of oil phase medium, 5 parts of crosslinking agent, 0.04 parts of initiator part, co-initiator 0.02 part, water 20 parts.

[0084] The reaction monomer is obtained by mixing acrylic acid, 2-acrylamide-2-methylpropanesulfonate and 2-vinyl-1,1-cyclopropanedicarboxamide; the acrylic acid, 2-acrylamide- The molar ratio of sodium 2-methylpropanesulfonate and 2-vinyl-1,1-cyclopropanedicarboxamide is 1:0.65:0.2.

[0085] The coagent is obtained by mixing sorbitan monooleate, sorbitan monooleate polyoxyethylene ether, polyethylene glycol laurate, and ammonium substances. The sorbitan monooleate The weight ratio of acid ester, sorbitan monooleate polyoxyethylene ether, polyethylene glycol laurate and ammonium substances is 1:0.6:0.8:0.35.

[0086] The ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com