Composite polyester hot melt adhesive, preparation method and preparation method of anti-scouring geotextile

A technology of polyester hot-melt adhesive and composite polyester, applied in the direction of soil protection, chemical instruments and methods, adhesives, etc., can solve the problems of low scouring strength, poor scouring performance, and poor soil retention performance of geotextiles. Achieve high erosion resistance, good impact resistance, and reduce rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

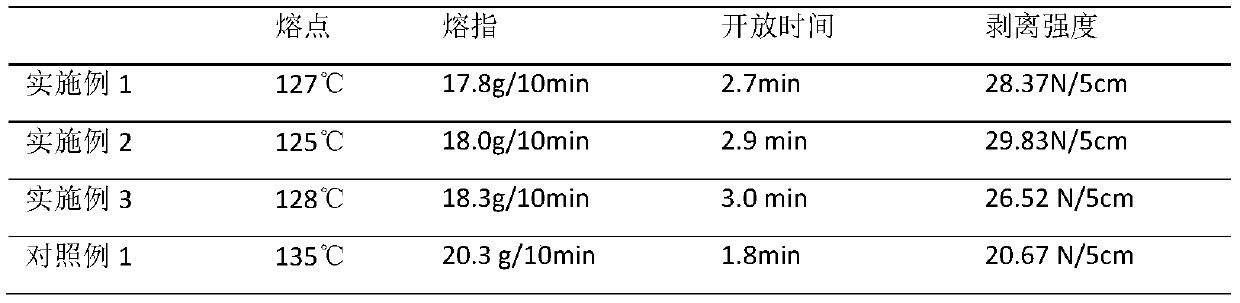

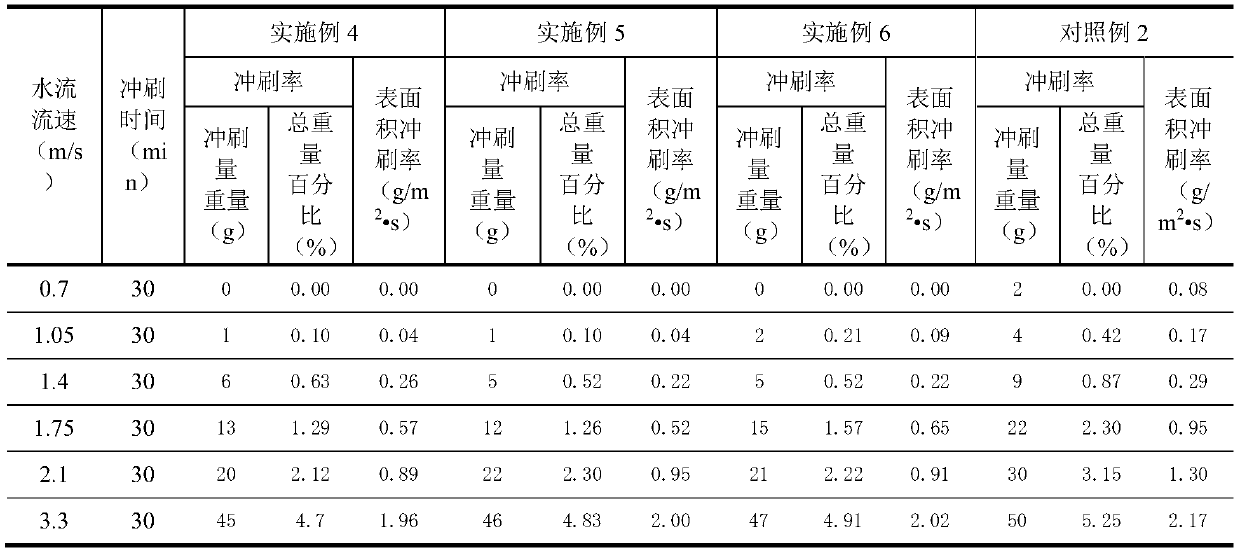

Examples

Embodiment 1

[0032] The preparation method of the composite polyester hot-melt adhesive of the present embodiment may further comprise the steps:

[0033] (1) Carry out esterification reaction with dibasic acid and dibasic alcohol under the action of titanium / cobalt composite catalyst, under the protection of nitrogen, the reaction temperature is 180 ℃, when the distilled water of esterification reaction is 95% of theoretical water output, After the esterification reaction is finished, an esterified product is obtained.

[0034] Wherein, the mass ratio of dibasic acid and dibasic alcohol is 1:1.2;

[0035] The dibasic acid is a mixture of terephthalic acid, isophthalic acid and 2-phenylglutaric acid, and the molar ratio of the respective addition amounts is 1:0.10:0.10.

[0036] The dihydric alcohol is a mixture of divinyl hexanediol, diethylene glycol and 1,4-butanediol, and the molar ratio of their respective addition amounts is 1.0:0.5:0.2.

Embodiment 2

[0041] The preparation method of the composite polyester hot-melt adhesive of the present embodiment may further comprise the steps:

[0042] (1) Carry out esterification reaction with dibasic acid and dibasic alcohol under the action of titanium / cobalt composite catalyst, under the protection of nitrogen, the reaction temperature is 190 ℃, when the distilled water of esterification reaction is 97% of theoretical water output, After the esterification reaction is finished, an esterified product is obtained.

[0043] Wherein, the mass ratio of dibasic acid and dibasic alcohol is 1:1.4;

[0044] The dibasic acid is a mixture of terephthalic acid, isophthalic acid and 2-phenylglutaric acid, and the molar ratio of the respective addition amounts is 1:0.20:0.20.

[0045] The dihydric alcohol is a mixture of divinyl hexanediol, diethylene glycol and 1,4-butanediol, and the molar ratio of their respective addition amounts is 1.1:0.6:0.3.

[0046] The titanium / cobalt composite catal...

Embodiment 3

[0050] The preparation method of the composite polyester hot-melt adhesive of the present embodiment may further comprise the steps:

[0051] (1) Carry out esterification reaction with dibasic acid and dibasic alcohol under the action of titanium / cobalt composite catalyst, under the protection of nitrogen, the reaction temperature is 200 ℃, when the distilled water of esterification reaction is 98% of theoretical water output, After the esterification reaction is finished, an esterified product is obtained.

[0052] Wherein, the mass ratio of dibasic acid and dibasic alcohol is 1:1.5;

[0053] The dibasic acid is a mixture of terephthalic acid, isophthalic acid and 2-phenylglutaric acid, and the molar ratio of the respective addition amounts is 1:0.30:0.30.

[0054] The dihydric alcohol is a mixture of divinyl hexanediol, diethylene glycol and 1,4-butanediol, and the molar ratio of their respective addition amounts is 1.2:0.7:0.4.

[0055] The titanium / cobalt composite catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com