Thin film deposition device and method adopting controllable magnetic field for screening laser plasma

A magnetic field screening and plasma technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem of different power density, smaller incident laser energy, composition of laser plasma plume, ion valence and Kinetic energy differences and other issues can be improved to improve quality and stability, facilitate equipment operation, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

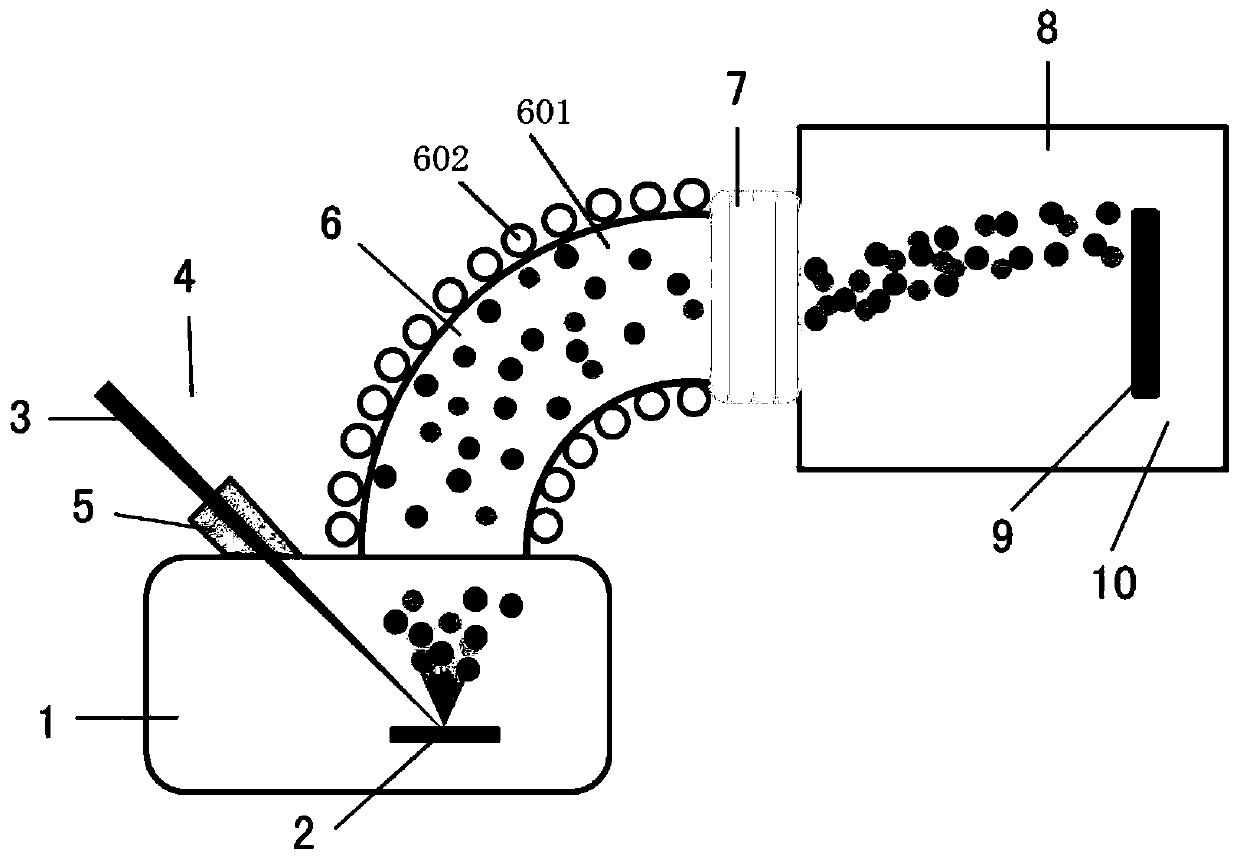

[0031] A film deposition device for screening laser plasma with a controllable magnetic field, comprising a laser plasma cavity 1, a laser incident window 5 is arranged on the laser plasma cavity 1, and a laser beam 3 enters the laser plasma cavity 1 through a focusing lens 4 and a laser incident window 5 The target material 2 placed on the target support, the laser plasma chamber 1 is connected to one end of the magnetic filter elbow 6 through a flange, the other end of the magnetic filter elbow 6 is connected to one end of the focusing magnetic field tube 7 through a flange, and the focusing magnetic field tube 7 is connected to the other end. One end is connected to the film deposition chamber 8 through a flange, and a substrate table 9 is arranged in the film deposition chamber 8, and a substrate is arranged on the substrate table 9.

[0032] A negative bias device 10 for applying a negative bias to the substrate table 9 is also provided in the film deposition chamber 8 . ...

Embodiment 2

[0036] A film deposition method for screening laser plasma with a controllable magnetic field, using a film deposition device for screening laser plasma with a controllable magnetic field described in Example 1, comprising the following steps:

[0037] Step 1, cleaning the substrate and fixing it on the substrate table 9 in the film deposition chamber 8;

[0038] Step 2, vacuuming the laser plasma chamber 1, the magnetic filter elbow 6, the focusing magnetic field cylinder 7 and the film deposition chamber 8;

[0039] Step 3, using an ion source to clean the coating surface of the substrate to remove oil and impurities absorbed by the coating surface of the substrate.

[0040] Step 4, introducing the laser beam 3 into the laser plasma cavity 1 through the laser incident window 5 . Adjust the distance from the focusing lens 4 to the target 2 by moving back and forth, focus the laser beam 3 on the surface of the target 2, and use the focused laser beam 3 to ablate the surface o...

Embodiment 3

[0050] A method for depositing a tetrahedral amorphous carbon film with a controllable magnetic field screening laser plasma, using a thin film deposition device for screening laser plasma with a controllable magnetic field described in Example 1, comprising the following steps:

[0051] Step 1. Fix the silicon wafer substrate with a diameter of 200mm on the substrate table in the thin film deposition chamber 8 after wiping with alcohol ether mixture and ultrasonic vibration cleaning.

[0052] Step 2: Close the doors of the laser plasma chamber 1 and the film deposition chamber 8, and start vacuuming the laser plasma chamber 1, the magnetic filter elbow 6, the focusing magnetic field cylinder 7 and the film deposition chamber 8.

[0053] Step 3. When the vacuum is pumped to 1×10 -5 Pa, use the ion source to clean the coating surface of the silicon wafer substrate for 10 minutes to remove the oil stains and impurities absorbed on the surface.

[0054] Step 4, using a KrF excim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com