Method for imprinting multiple nano-patterns based on photoresponsive polymer

A nano-pattern and polymer technology, applied in the fields of nanotechnology, optics, opto-mechanical equipment, etc., can solve problems such as inability to imprint nanostructures, and achieve the effect of simple and convenient method and expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

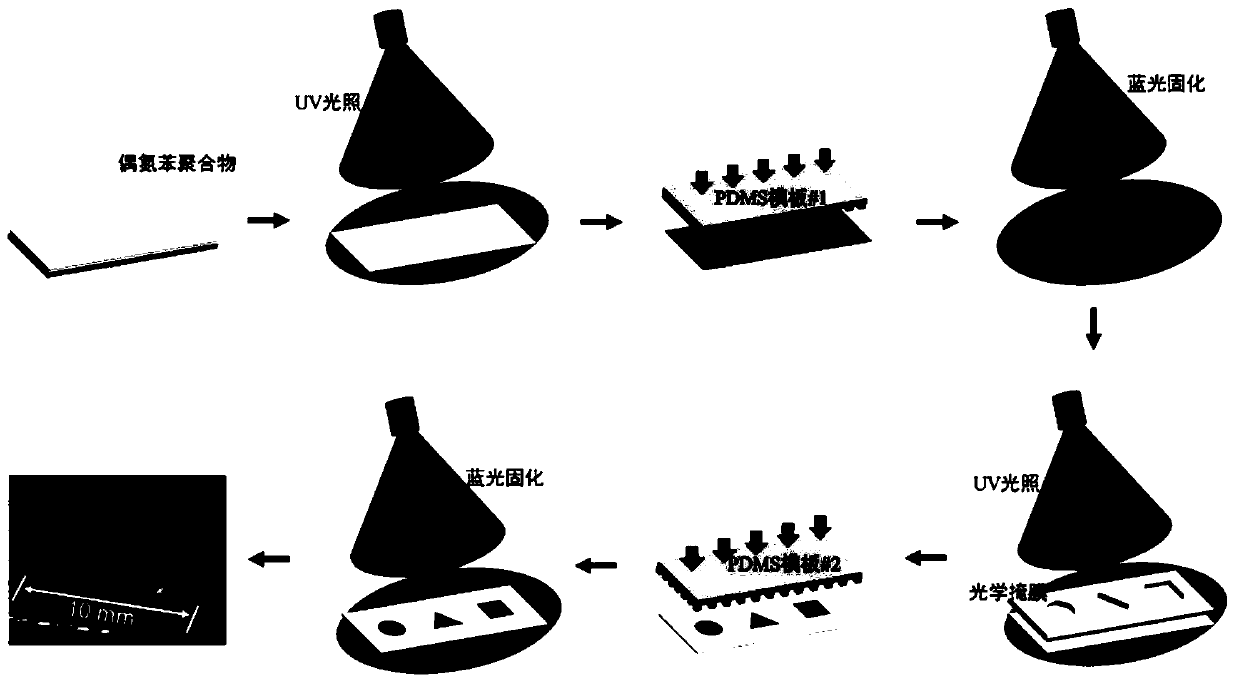

Method used

Image

Examples

Embodiment 1

[0058] 1. Selection of materials

[0059]

[0060] For the azobenzene homopolymer shown in formula I, when R 1 is methyl, R 3 , R 4 , R 5 and R 6 Both are H atoms, when n is about 40 (molecular weight is about 20,000), different spacer m and end group R 2 The photoinduced glass transition temperature of the polymer (T g ) transformation results are shown in Table 1.

[0061] Table 1. Trans / cis state glass transition temperature of some azobenzene homopolymers

[0062]

[0063] This embodiment adopts m=6, end group R 2 It is a n-butyl azobenzene homopolymer whose main chain is methyl methacrylate type, recorded as PM6AzC4, with a molecular weight of 32 000 and a dispersity of 1.91. The glass transition temperature measured by DSC is 78°C. The post glass transition temperature is 15°C.

[0064] 2. Film Preparation

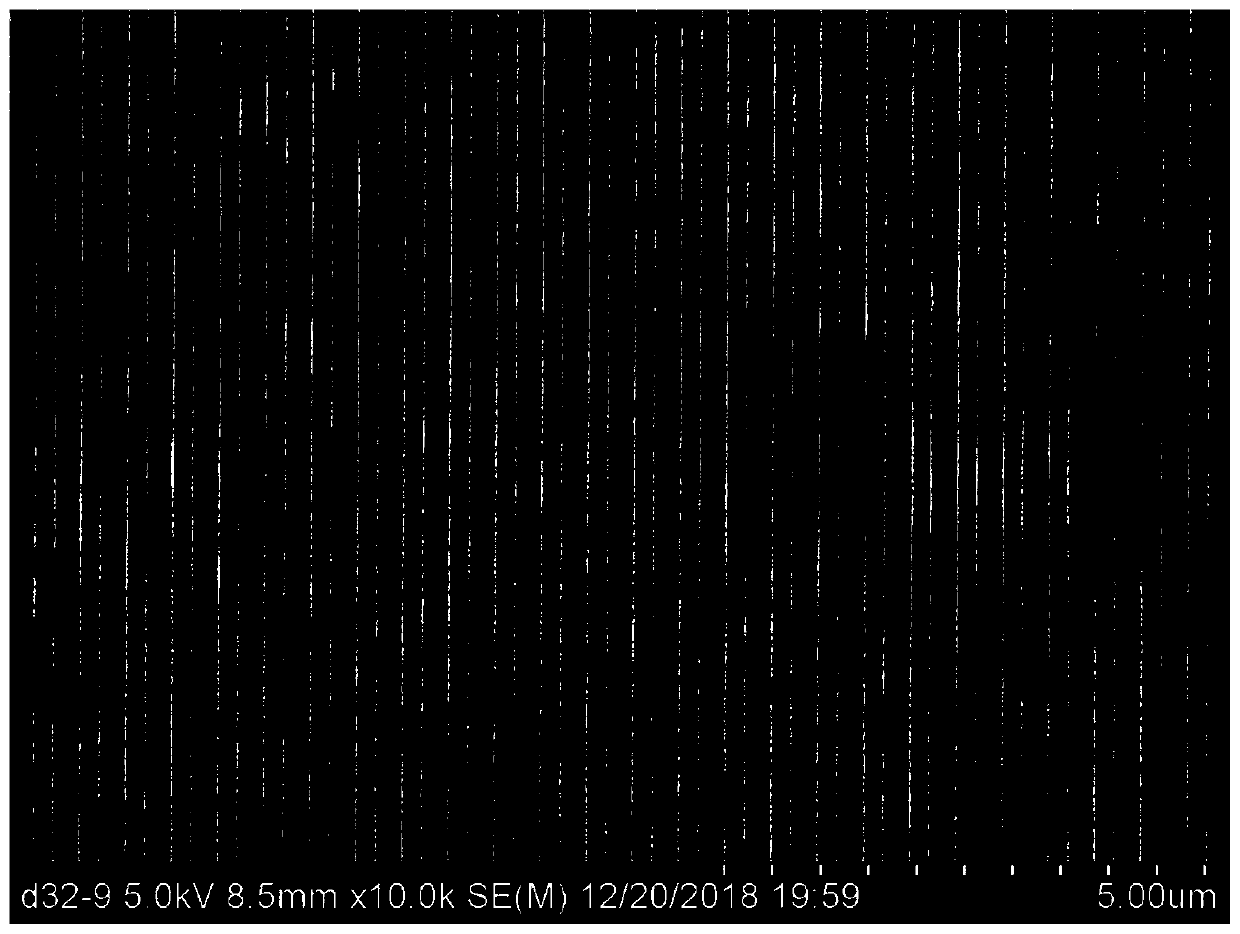

[0065] The silicon wafer is cleaned and dried, and a layer of PM6AzC4 polymer (4wt%, solvent is tetrahydrofuran) is spin-coated on the silicon wafer....

Embodiment 2

[0073] 1. Selection of materials

[0074] With embodiment 1.

[0075] 2. Film Preparation

[0076] Select a commercial PET film with a thickness of about 10 microns, drop-coat a layer of PM6AzC4 polymer (4wt%, solvent is tetrahydrofuran) on the PET film to obtain a polymer film with a thickness of about 1 micron, and store it away from light.

[0077] 3. First impression

[0078] Same as Example 1, except that the template for imprinting is changed to a nickel template.

[0079] 4. Second impression

[0080] Same as Example 1, except that the template for imprinting is changed to a nickel template. The embossing effect is the same as in Example 1, and the structural color effect is as follows Figure 7 As shown, the pattern color changes with the azimuth angle and polar angle simultaneously (same as embodiment 1).

Embodiment 3

[0082] 1. Selection of materials

[0083] Adopt m=6, end group R 2 It is an ethoxy group, the main chain is azobenzene homopolymer of methyl methacrylate type, recorded as PM6AzOC2, the molecular weight is 59 000, and the dispersion is 2.12.

[0084] 2. Film Preparation

[0085] With embodiment 1.

[0086] 3. First impression

[0087] Same as Example 1, except that the whole process is carried out on a hot stage at 50°C.

[0088] 4. Second impression

[0089] Same as Example 1, except that the whole process is carried out on a hot stage at 50°C. The embossing effect and structural color effect are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com