Preparation of chitosan/cellulose aerogel balls with high formaldehyde adsorption characteristics

A formaldehyde adsorption, cellulose technology, applied in the directions of alkali metal oxides/hydroxides, inorganic chemistry, alkali metal compounds, etc., can solve the problems of lack of specificity of formaldehyde, reduced adsorption rate, etc., and achieve mild conditions and effective removal , the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

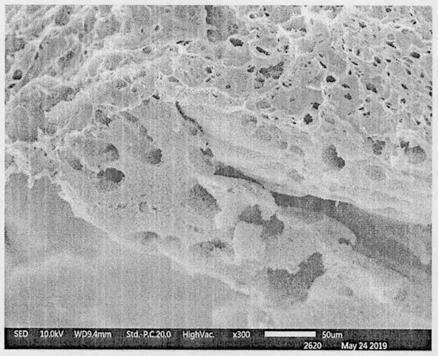

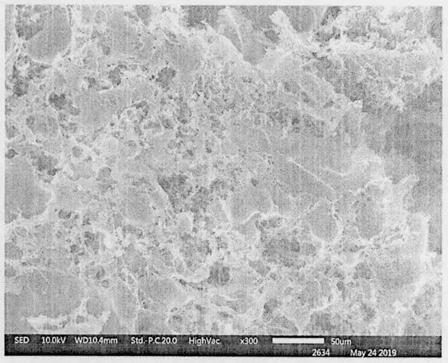

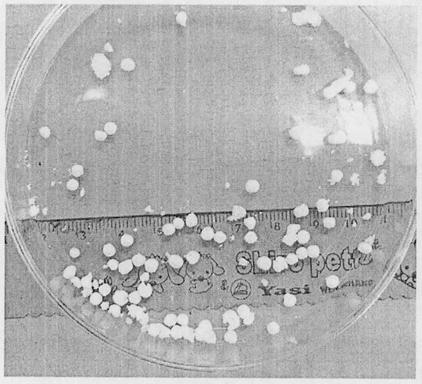

[0022] A kind of preparation method of chitosan / cellulose formaldehyde adsorption airgel:

[0023] Step (1) freeze-dry the dissolving slurry after acidolysis with hydrochloric acid / ethanol, dissolve it in NaOH / urea / water solution, and stir it at -12°C using a low-temperature cooling liquid circulation pump to obtain a mass concentration of 1 wt% to 5 wt%. Cellulose solution. The solution is added dropwise into the acidic regeneration solution with a rubber dropper, and solidified for 5-30 minutes to obtain cellulose gel balls. The obtained gel balls are replaced and washed with distilled water and ethanol for 3 to 5 times to finally obtain cellulose wet gel balls.

[0024] Step (2) adding chitosan into the NaOH / urea / water mixed solution, and freezing and thawing repeatedly to obtain a chitosan solution with a mass fraction of 1wt%-5wt%. Then immerse the cellulose wet gel balls obtained in step (1) in chitosan solutions with different mass fractions at normal temperature for ...

example 2

[0027] A kind of preparation method of chitosan / cellulose formaldehyde adsorption airgel:

[0028] Step (1) freeze-dry the dissolving pulp after hydrochloric acid / ethanol acid hydrolysis, dissolve it in NaOH / urea / water solution, and use a low-temperature cooling liquid circulation pump to stir at -12°C to obtain cellulose with a mass concentration of 5 wt%. solution. The solution is added dropwise into the acidic regeneration solution with a rubber dropper, and solidified for 5-30 minutes to obtain cellulose gel balls. The obtained gel balls are replaced and washed with distilled water and ethanol for 3 to 5 times to obtain cellulose wet gel balls.

[0029] Step (2) Chitosan is added to NaOH / urea / water (mass ratio is 6 / 5 / 98) mixed solution, after repeated freezing and thawing, a chitosan solution with a mass fraction of 2wt% is obtained. Then immerse the cellulose gel balls obtained in the step (1) in chitosan solutions with different mass fractions at normal temperature for...

example 3

[0032] A kind of preparation method of chitosan / cellulose formaldehyde adsorption airgel:

[0033] Step (1) Add the cellulose acid-hydrolyzed with hydrochloric acid / ethanol to the mixed solution of urea / NaOH / water at a temperature of -15 to -12° C., and stir thoroughly to obtain a cellulose solution with a mass fraction of 5 wt%. The solution is added dropwise into the acidic regeneration solution with a rubber dropper, and cured for 5-30 minutes to obtain cellulose wet gel balls. The obtained gel balls are replaced and washed with distilled water and ethanol for 3 to 5 times to obtain cellulose wet gel balls.

[0034] Step (2) Chitosan is added to NaOH / urea / water mixture and repeatedly frozen and thawed to obtain a chitosan solution with a mass fraction of 2 wt%. Then immerse the cellulose gel balls obtained in step (1) in chitosan solutions with different mass fractions for 3-5 hours, and the immersion temperature is 0-60°C to obtain different cellulose / chitosan wet gel bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com