Electrostatic spinning method for preparing micro-nano fibers in directional alignment

A technology of micro-nano fiber and electrospinning, which is applied in electrospinning, fiber processing, textiles and papermaking, etc., and can solve the problems of difficult removal of fibers, large output of micro-nano fibers, research and application limitations of micro-nano fibers, etc. , to achieve the effect of high order and long length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of electrospinning solution: silk fibroin powder was obtained after cocoon degumming, dissolution, dialysis, and freeze-drying. An appropriate amount of silk fibroin powder was dissolved in a formic acid solution to obtain a 12wt% regenerated silk fibroin solution, and stirred at room temperature for 24 hours to obtain an electrospinning solution.

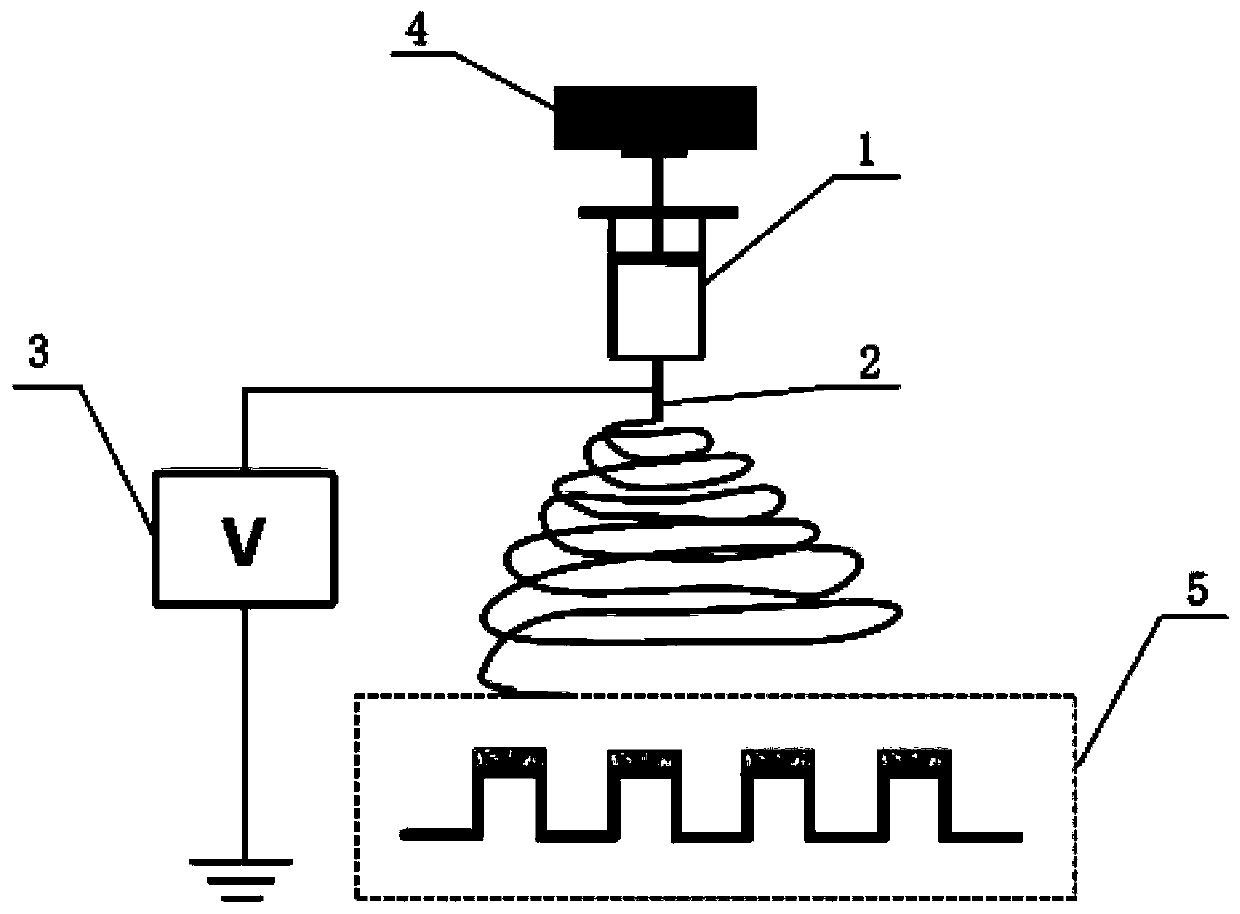

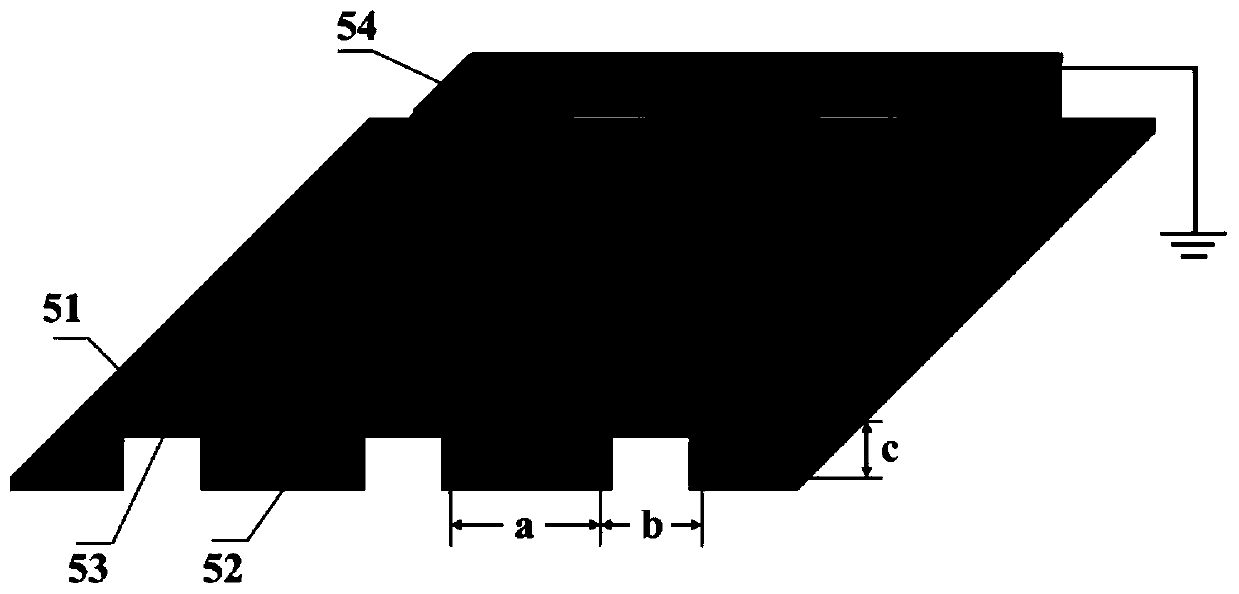

[0041] Preparation of ordered fibers by electrospinning: put the electrospinning solution into the syringe 1 of the above-mentioned electrospinning device, and perform electrospinning. The receiving component 5 is used to receive the ordered fibers, wherein the width of the energized electrode 51 in the receiving component 5 is 0.8 cm, the width of the insulating part 52 is 1 cm, and the energized electrode 51 is 1 cm higher than the insulating part 52 . During electrospinning, the temperature was 25°C, the spinning distance was 18cm, the voltage was 10kV, and the spinning time was 3h.

[0042] In this example, ...

Embodiment 2

[0044] Preparation of electrospinning solution: silk fibroin powder was obtained after cocoon degumming, dissolution, dialysis, and freeze-drying. An appropriate amount of silk fibroin powder was dissolved in a formic acid solution to obtain a 12wt% regenerated silk fibroin solution, and stirred at room temperature for 24 hours to obtain an electrospinning solution.

[0045] Preparation of ordered fibers by electrospinning: put the electrospinning solution into the syringe 1 of the above-mentioned electrospinning device, and perform electrospinning. The receiving component 5 is used to receive the ordered fibers, wherein the width of the energized electrode 51 in the receiving component 5 is 0.5 cm, the width of the insulating part 52 is 2 cm, and the energized electrode 51 is 1 cm higher than the insulating part 52 . During electrospinning, the temperature was 20°C, the spinning distance was 15cm, the voltage was 15kV, and the spinning time was 2h.

[0046] In this example, ...

Embodiment 3

[0048] Preparation of electrospinning solution: silk fibroin powder was obtained after cocoon degumming, dissolution, dialysis, and freeze-drying. An appropriate amount of silk fibroin powder was dissolved in a formic acid solution to obtain a 12wt% regenerated silk fibroin solution, and stirred at room temperature for 24 hours to obtain an electrospinning solution.

[0049] Preparation of ordered fibers by electrospinning: put the electrospinning solution into the syringe 1 of the above-mentioned electrospinning device, and perform electrospinning. The receiving component 5 is used to receive the ordered fibers, wherein the width of the energized electrode 51 in the receiving component 5 is 1.5 cm, the width of the insulating part 52 is 3 cm, and the energized electrode 51 is 2 cm higher than the insulating part 52 . During electrospinning, the temperature was 30°C, the spinning distance was 20cm, the voltage was 20kV, and the spinning time was 4h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com