Wound dressing based on hydrogel-core-shell microspheres and preparation method thereof

A technology of core-shell microspheres and wound dressings, applied in bandages, medical science, etc., can solve the problems of low drug loading, low encapsulation rate, and fast release rate of solid microspheres, shorten the wound healing time, and promote wound healing. Effect of tissue regeneration and promotion of wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention firstly provides a kind of preparation method of the wound dressing based on hydrogel-core-shell microsphere, and this method comprises:

[0032] Step 1: Using the coaxial electrostatic spray method, the inner axis is RCSPs solution, the outer axis is sodium alginate solution, and the droplets formed by coaxial electrostatic spraying are collected in calcium chloride solution for cross-linking to obtain sodium alginate / Core-shell microspheres of RCSPs;

[0033] Step 2: Mix gelatin and polyvinyl alcohol solution to obtain a homogeneous gel precursor, then add the core-shell microspheres of sodium alginate / RCSPs in step 1 to the homogeneous gel precursor, and stir evenly to obtain a core-shell Microsphere / hydrogel precursor mixture;

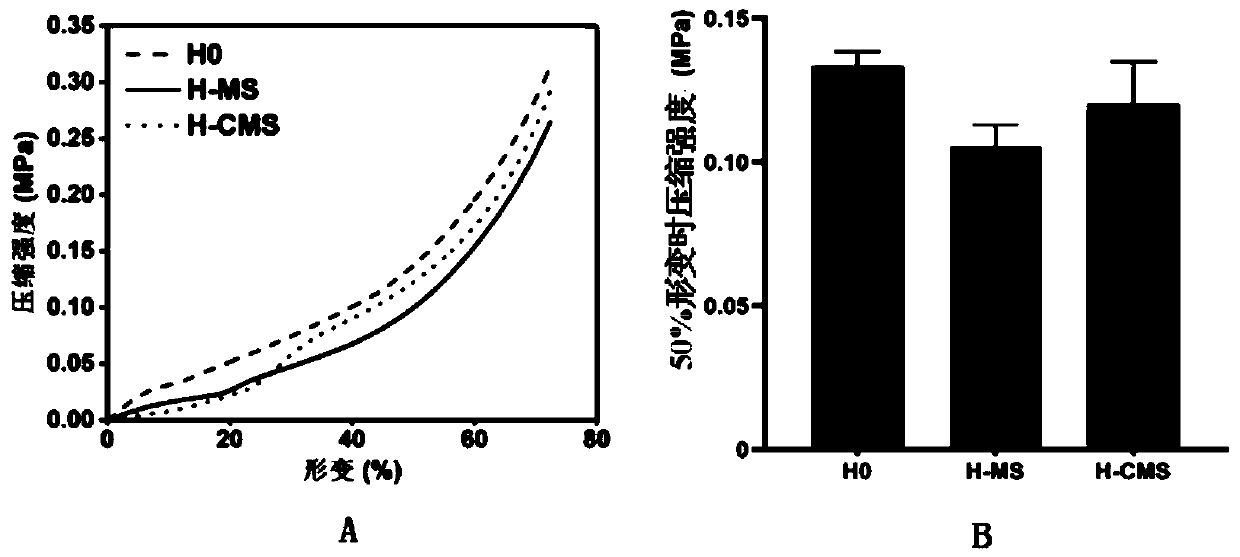

[0034] Step 3: The core-shell microsphere / hydrogel precursor mixture obtained in step 2 was repeatedly freeze-thawed at least three times and freeze-dried to obtain a wound dressing based on hydrogel-core-shell micros...

Embodiment 1

[0040]The preparation of the core shell microsphere of embodiment 1 sodium alginate / RCSPs

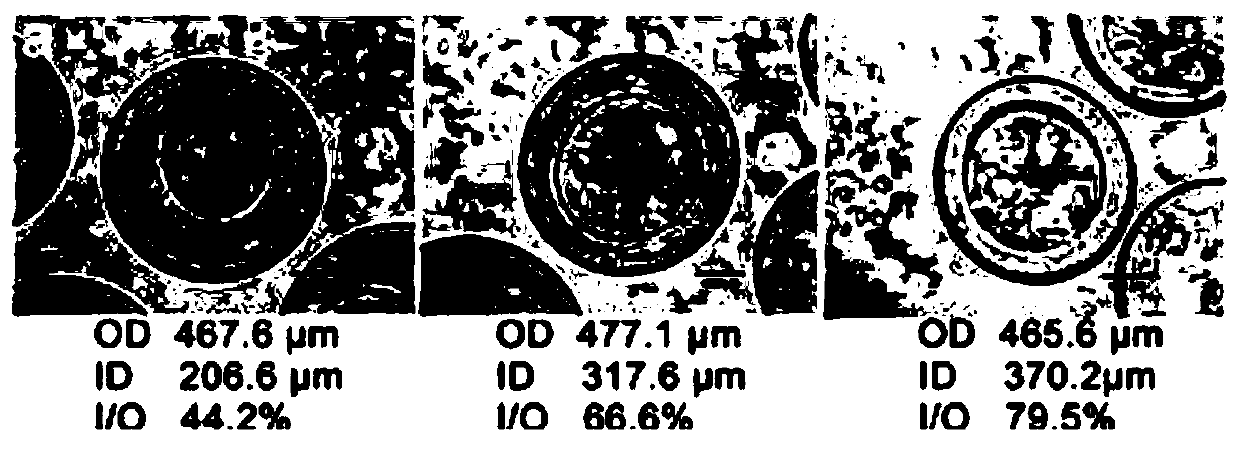

[0041] First sodium alginate and anhydrous calcium chloride were dissolved in deionized water respectively, the concentration of the described sodium alginate solution was 1.5% (w / v), and the concentration of the anhydrous calcium chloride solution was 3% (w / v). / v), then RCSPs (purchased from Jilin Province Fangping Technology Co., Ltd.) were dissolved in deionized water, the concentration of RCSPs solution was 3% (w / v), and 10% (w / v) glycerin was added for subsequent To protect the activity of RCSPs during the freeze-drying process, the coaxial electrostatic spraying method is adopted, the inner axis is RCSPs solution, the outer axis is sodium alginate solution, the inner diameter of the inner axis is 0.8mm, the outer diameter of the outer axis is 1.4mm, the inner axis The flow rate ratio to the outer shaft is 1:2, 1:3.5, 1:5 respectively, the unit is ml / h, the applied voltage is 12kv...

Embodiment 2

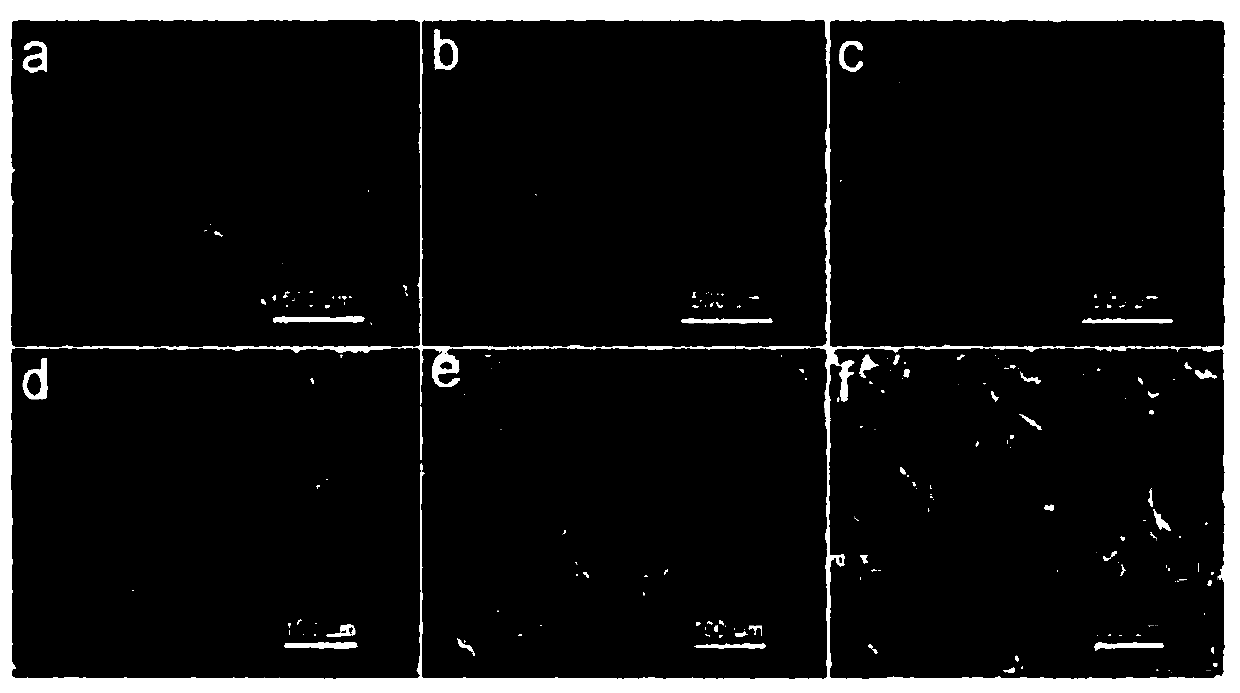

[0049] Add polyvinyl alcohol into distilled water, preferably magnetically stir at 80°C for 4h until dissolved, cool to 50°C to obtain a 4% (w / v) polyvinyl alcohol solution, the mass ratio of gelatin and polyvinyl alcohol is 1:1 , adding gelatin to the polyvinyl alcohol solution, stirring for 2h to a homogeneous solution, to obtain a homogeneous gel precursor containing two polymer solutions, and then 1 g of the sodium alginate / RCSPs core-shell prepared in Example 1 The balls (microspheres with a flow rate of 1:3.5 between the inner shaft and the outer shaft) were dispersed into 5ml of the gel precursor, and a completely uniform core-shell microsphere / hydrogel precursor mixture was formed by magnetic stirring, and the air bubbles were removed by ultrasonic ( BILON3-120A, Shanghai, China), the mixed solution was poured into a 6-well plate, frozen at -20°C for 20 hours, thawed at room temperature, repeated freezing and thawing three times, and freeze-dried to obtain a wound dress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com