Manganese-cerium composition with flaky anatase type TiO2 as carrier and preparation and application

An anatase-type, composite technology, applied in the field of denitrification catalysts, can solve the problem of low catalytic efficiency of denitrification catalysts, and achieve superior denitrification activity and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A flaky anatase TiO 2 The preparation method of the manganese-cerium complex comprising the following steps:

[0038] (1) Preparation of flaky anatase-type titanium dioxide that preferentially exposes the {001} crystal face: 0.8ml of hydrofluoric acid with a mass ratio of 48% was added dropwise to 5ml of tetrabutyl titanate under stirring conditions, and the The mixed solution was transferred to a 20ml polytetrafluoroethylene-lined stainless steel autoclave, and then kept at 200°C for 24 hours in a blast drying oven, then taken out and cooled to room temperature naturally. The product was washed three times with deionized water and ethanol, and then calcined in a temperature-programmed muffle furnace at 450° C. for 3 hours to obtain 0.9 g of flaky anatase titanium dioxide.

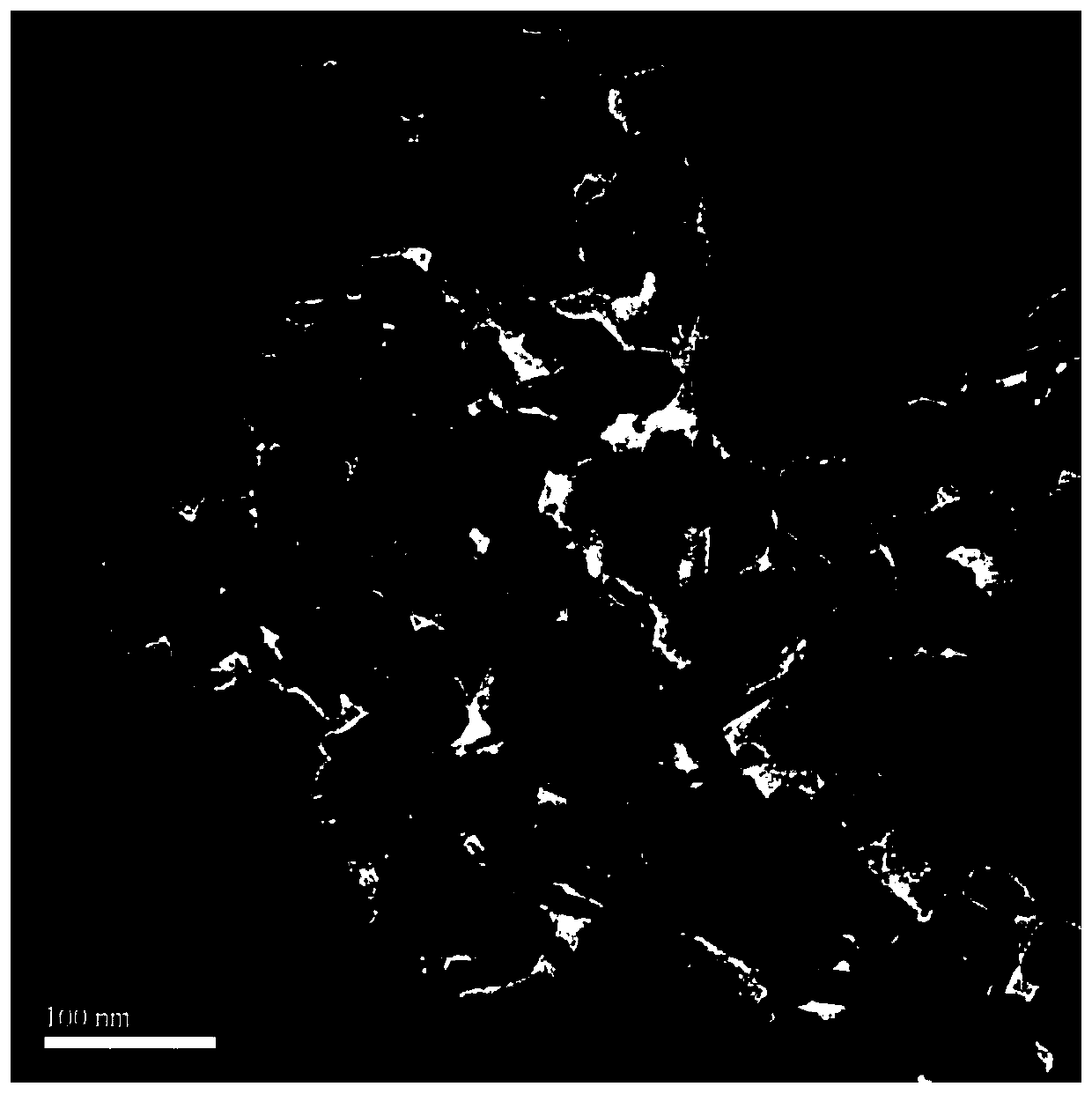

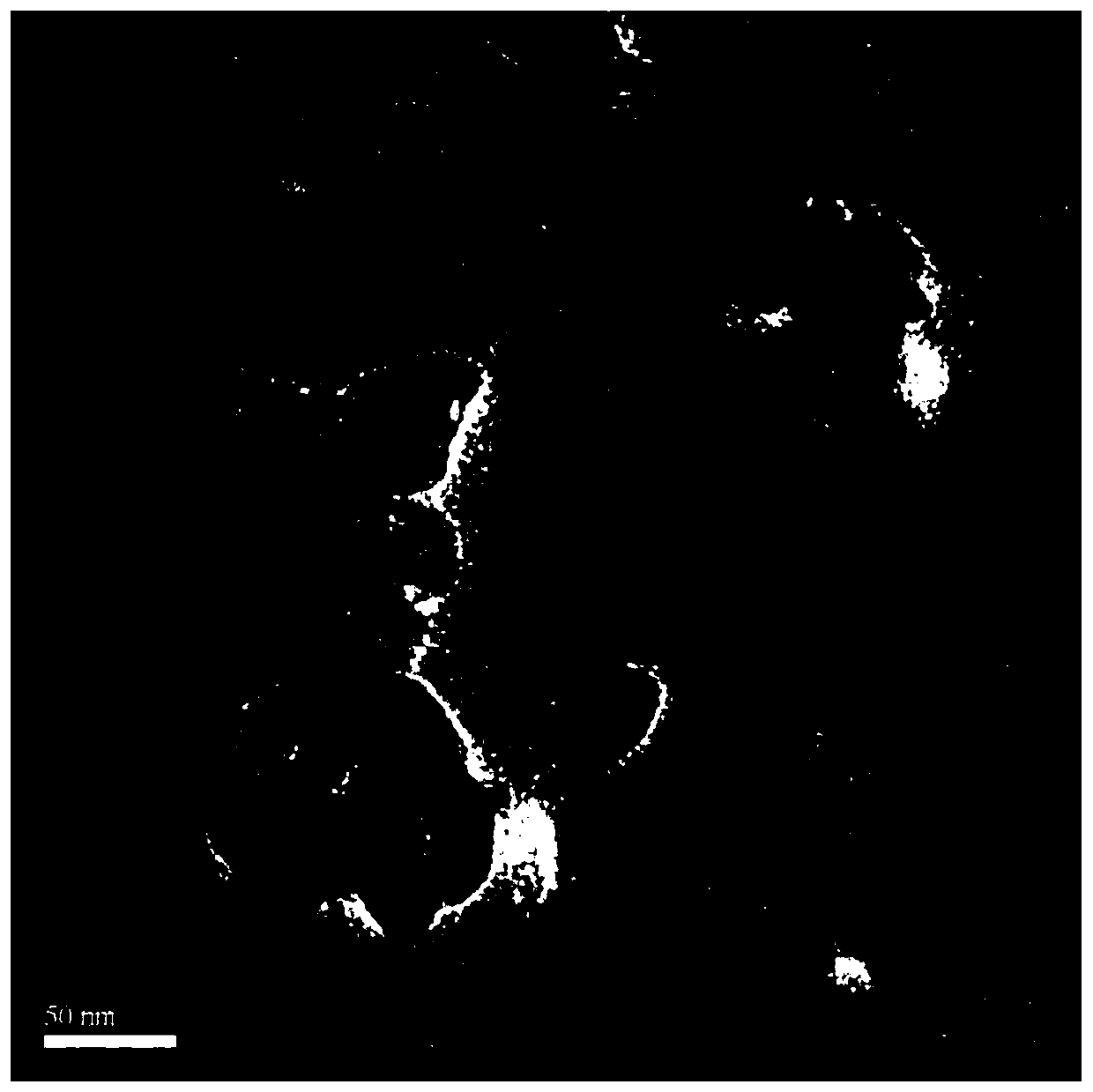

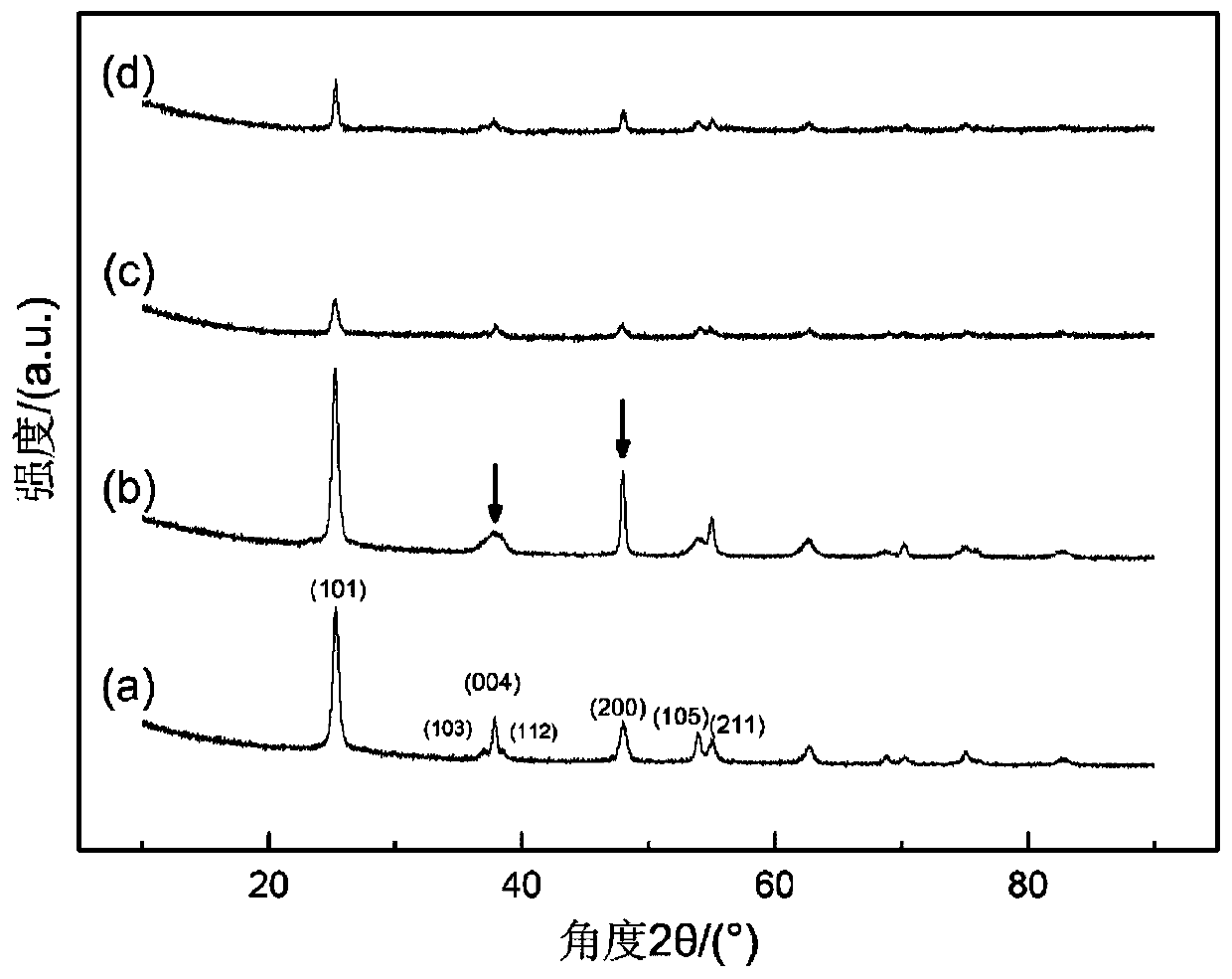

[0039] figure 1 It is a TEM image of anatase titanium dioxide preferentially exposing the {001} crystal plane obtained in step (1) of Example 1 of the present invention. Depend on figure 1 It ca...

Embodiment 2

[0058] A flaky anatase TiO 2 The preparation method of the manganese-cerium complex comprising the following steps:

[0059] (1) Preparation of anatase-type titanium dioxide that preferentially exposes the {001} crystal face: 1.2ml of hydrofluoric acid with a mass ratio of 48% was added dropwise to 12ml of tetrabutyl titanate under stirring conditions, and the mixed solution Transfer to a 40ml polytetrafluoroethylene-lined stainless steel autoclave, then keep it in a blast drying oven at 180°C for 24 hours, take it out and cool it down to room temperature naturally. The product was washed three times with deionized water and ethanol, and then calcined in a temperature-programmed muffle furnace at 400° C. for 4 hours to obtain 1.3 g of flaky anatase titanium dioxide.

[0060] (2) The active component MnO on the {001} crystal surface of anatase titanium dioxide x , CeO x Loading: Prepare manganese cerium denitrification catalyst by impregnation method; weigh 1.303g cerium nit...

Embodiment 3

[0072] A flaky anatase TiO 2 The preparation method of the manganese-cerium complex comprising the following steps:

[0073] (1) Preparation of anatase-type titanium dioxide that preferentially exposes the {001} crystal face: 1.2ml of hydrofluoric acid with a mass ratio of 50% was added dropwise to 8ml of tetrabutyl titanate under stirring conditions, and the mixed solution Transfer to a 20ml polytetrafluoroethylene-lined stainless steel autoclave, then keep it in a blast drying oven at 160°C for 12 hours, take it out and cool it down to room temperature naturally. The product was washed three times with deionized water and ethanol, and then calcined in a temperature-programmed muffle furnace at 500° C. for 4 hours to obtain 1.5 g of flaky anatase titanium dioxide.

[0074] (2) The active component MnO on the {001} crystal surface of anatase titanium dioxide x , CeO x Loading: Prepare manganese cerium denitrification catalyst by impregnation method; weigh 2.371g cerium nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com