Aerated concrete block

An aerated concrete and block technology, applied in the field of building materials, can solve the problems of easily affecting the compressive strength of aerated concrete blocks, easily becoming brittle, and affecting the stability of buildings, etc. Compressive strength and oxidation resistance, good corrosion resistance, and the effect of enhancing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

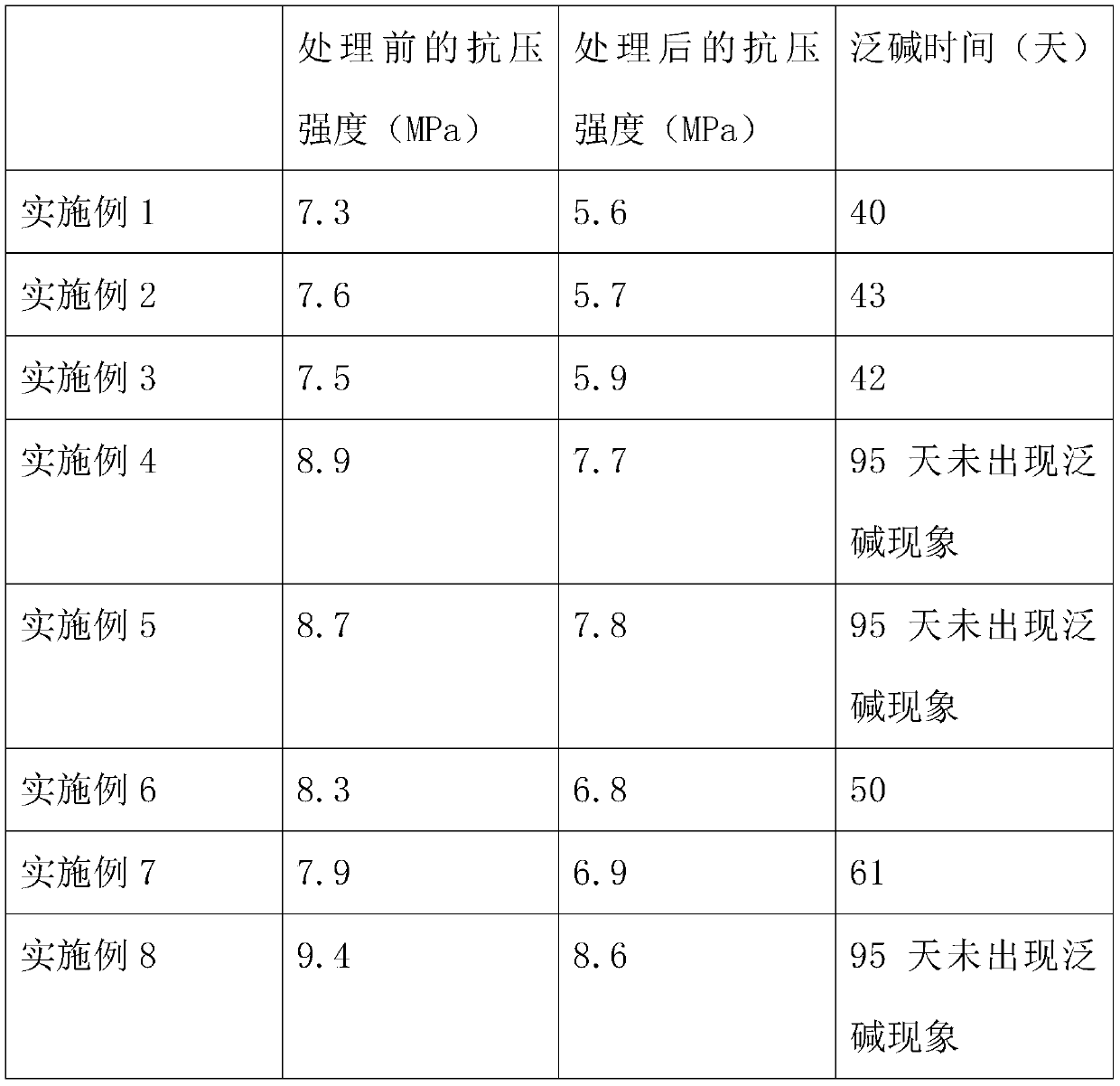

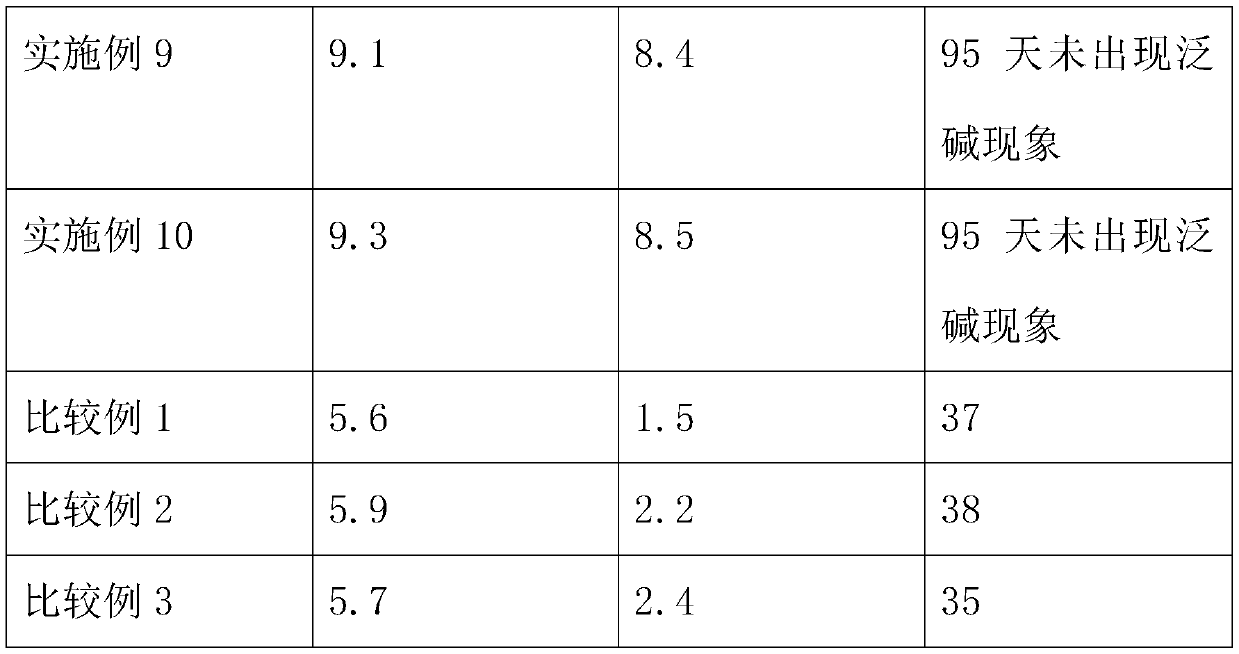

Examples

Embodiment 1

[0052] An aerated concrete block, comprising the following components in parts by mass:

[0053] 60kg of water; 20kg of Portland cement; 27.5kg of sand; 35kg of stone; 0.5kg of aluminum powder; 4kg of water reducing agent; 3kg of methyl o-hydroxybenzoate; 3kg of lecithin;

[0054] The preparation method of air-entrained concrete blocks is as follows:

[0055] S1. Crush 27.5kg of sand and 35kg of stone and mix them into a ball mill to grind them into a mixture with a fineness of 250 mesh. Then add the mixture and 30kg of water into the stirring tank, stir at a speed of 150r / min, and stir evenly to form a mixture. pulp;

[0056] S2. While stirring, add the uniformly stirred slurry in S1, 30kg of water, 20kg of Portland cement, and 4kg of water reducing agent, keep the temperature at 45°C, and react for 180s;

[0057] S3. Add 0.5kg of aluminum powder while stirring, keep the temperature at 50°C, and react for 60s;

[0058] S4, add methyl o-hydroxybenzoate 3kg, lecithin 3kg, ac...

Embodiment 2

[0063] An aerated concrete block, comprising the following components in parts by mass:

[0064] 65kg of water; 15kg of Portland cement; 30kg of sand; 30kg of stone; 1kg of aluminum powder; 5kg of water reducing agent; 5kg of methyl o-hydroxybenzoate; 1kg of lecithin;

[0065] The preparation method of air-entrained concrete blocks is as follows:

[0066] S1. Crush 30kg of sand and 30kg of stone and mix them into a ball mill to grind them into a mixture with a fineness of 250 mesh. Then add the mixture and 32.5kg of water into the stirring tank, stir at a speed of 150r / min, and stir evenly to form a mixture. pulp;

[0067] S2. While stirring, add the uniformly stirred slurry in S1, 32.5kg of water, 15kg of Portland cement, and 5kg of water reducing agent, keep the temperature at 45°C, and react for 180s;

[0068] S3. Add 1kg of aluminum powder while stirring, keep the temperature at 50°C, and react for 60s;

[0069] S4, add methyl o-hydroxybenzoate 5kg, lecithin 1kg, acryli...

Embodiment 3

[0074] An air-entrained concrete block is characterized in that it includes the following components in parts by mass:

[0075] 70kg of water; 17.5kg of Portland cement; 25kg of sand; 32.5kg of stone; 0.8kg of aluminum powder; 3kg of water reducing agent; 4kg of methyl o-hydroxybenzoate; 2kg of lecithin;

[0076] The preparation method of air-entrained concrete blocks is as follows:

[0077] S1. Crush 25kg of sand and 32.5kg of stone and mix them into a ball mill to grind them into a mixture with a fineness of 250 mesh. Then add the mixture and 35kg of water into the stirring tank, stir at a speed of 150r / min, and stir evenly to form a mixture. pulp;

[0078] S2. While stirring, add the uniformly stirred slurry in S1, 35kg of water, 17.5kg of Portland cement, and 3kg of water reducing agent, keep the temperature at 45°C, and react for 180s;

[0079] S3. Add 0.8kg of aluminum powder while stirring, keep the temperature at 50°C, and react for 60s;

[0080] S4, add methyl o-hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com