Modified cellulose nanofiber stable Pickering emulsion and preparation method thereof

A cellulose and nanofiber technology is applied in the field of modified cellulose nanofiber-stabilized Pickering emulsion and its preparation, which can solve the problems of secondary environmental pollution, expensive catalysts, toxic solvents, etc. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare an aqueous dispersion of cellulose nanofibers with a mass fraction of 2.0%, and adjust its pH to 3.0, add γ-aminopropyltriethoxysilane accounting for 5% of the mass of cellulose nanofibers to the system, and stir at room temperature for 6h , to obtain aminated cellulose nanofiber solution; prepare 60mL EDC / NHS ethanol solution, in which the mass fractions of EDC and NHS are 1.5% and 1.0% respectively, dissolve 0.1g oleic acid in EDC / NHS ethanol solution for activation for 15min, then add 10 mL of aminated cellulose nanofiber solution was stirred at room temperature for 24 h, the precipitate was collected after filtration and deionized water washing, and the precipitate was freeze-dried to obtain oleic acid modified cellulose nanofiber powder.

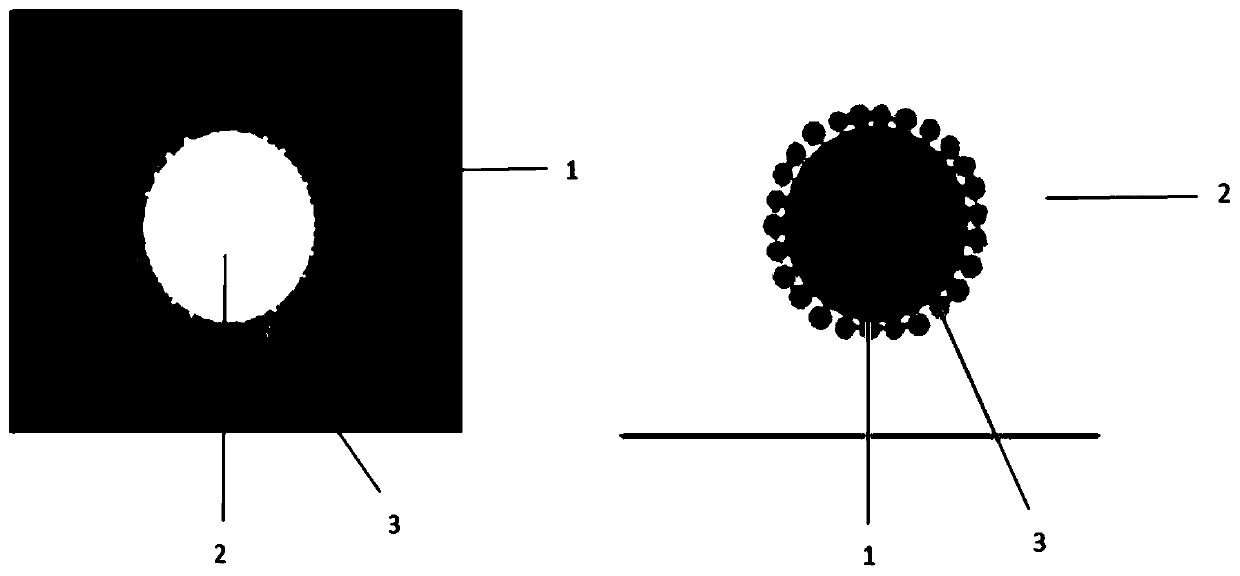

[0022] Disperse 0.02 g of oleic acid modified cellulose nanofiber powder in 2 mL of deionized water to form a modified cellulose nanofiber dispersion with a mass fraction of 1.0%, add 2 mL of dodecane to form an oil-water ...

Embodiment 2

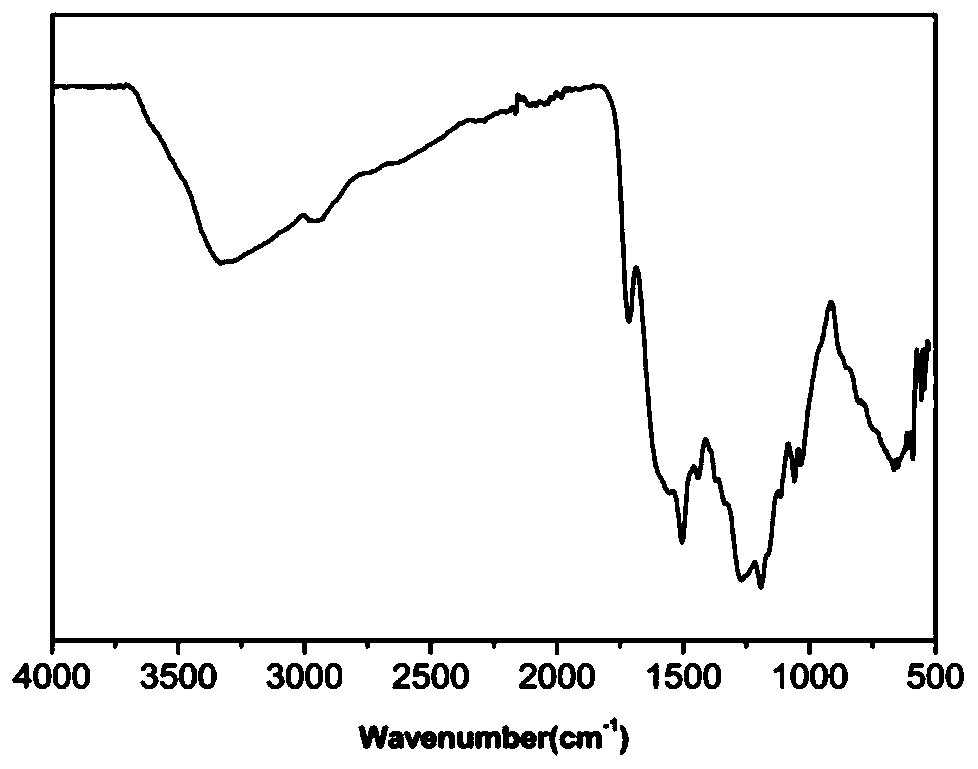

[0024] Prepare an aqueous dispersion of cellulose nanofibers with a mass fraction of 2.0%, and adjust its pH to 3.0, add γ-aminopropyltriethoxysilane accounting for 5% of the mass of cellulose nanofibers to the system, and stir at room temperature for 6h , to obtain aminated cellulose nanofiber solution; prepare 60mL EDC / NHS ethanol solution, wherein the mass fractions of EDC and NHS are 1.5% and 1.0% respectively, dissolve 0.2g oleic acid in EDC / NHS ethanol solution and activate for 15min, then add 10mL of aminated cellulose nanofiber solution, stirred at room temperature for 24h, filtered and washed with deionized water to collect the precipitate, freeze-dried the precipitate to obtain oleic acid modified cellulose nanofiber powder, its infrared spectrum is as follows figure 2 shown.

[0025] Disperse 0.02g of oleic acid modified cellulose nanofiber powder in 2mL of deionized water to form a dispersion of modified cellulose nanofibers with a mass fraction of 1.0%, add 2mL o...

Embodiment 3

[0027] Prepare an aqueous dispersion of cellulose nanofibers with a mass fraction of 2.0%, and adjust its pH to 3.0, add γ-aminopropyltriethoxysilane accounting for 5% of the mass of cellulose nanofibers to the system, and stir at room temperature for 6h , to obtain aminated cellulose nanofiber solution; prepare 60mL EDC / NHS ethanol solution, in which the mass fractions of EDC and NHS are 1.5% and 1.0% respectively, dissolve 0.4g oleic acid in EDC / NHS ethanol solution and activate for 15min, then add 10 mL of aminated cellulose nanofiber solution was stirred at room temperature for 24 h, the precipitate was collected after filtration and deionized water washing, and the precipitate was freeze-dried to obtain oleic acid modified cellulose nanofiber powder.

[0028]Disperse 0.02g of oleic acid modified cellulose nanofiber powder in 2mL of deionized water to form a dispersion of modified cellulose nanofibers with a mass fraction of 1.0%, add 2mL of dodecane to form an oil-water mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com