High-temperature-resistant wave-absorbing coating and preparation method and application thereof

A wave-absorbing coating and high-temperature-resistant technology, which is applied to radiation-absorbing coatings, anti-corrosion coatings, and fire-resistant coatings, can solve problems such as unsatisfactory impedance matching characteristics, large graphene dielectric constant, and poor wave-absorbing performance, and achieve anti-corrosion And excellent salt spray resistance, high hardness, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

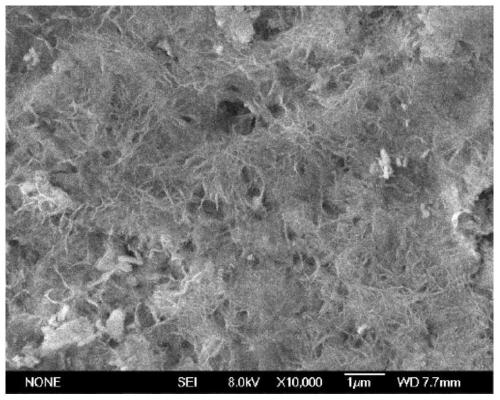

[0023] In some preferred embodiments, the Fe 3 o 4 -Graphene-SiO 2 The preparation method of composite nanoparticles comprises:

[0024] FeCl 3 ·6H 2 O, sodium acetate and graphene slurry are mixed in the mixed solution in ethylene glycol and diethylene glycol, then carry out hydrothermal reaction in the sealed reactor, after the reaction finishes, collect the obtained mixed solution by magnet The solid is washed and dried to obtain Fe 3 o 4 - Graphene nanocomposites, wherein the hydrothermal reaction temperature is 180-190° C., and the time is 7-9 hours;

[0025] And, the obtained 0.25~0.29g Fe 3 o 4 - Graphene nanocomposites are dispersed in a mixed solution of 70-75mL ethylene glycol, 30-32mL deionized water and 1.2-1.5mL ammonia water, then add 0.35-0.41mL tetraethyl orthosilicate under stirring conditions, and React for 12-15 hours, wash with water, and dry to obtain Fe 3 o 4 -Graphene-SiO 2 composite nanoparticles.

[0026] Further, the graphene slurry inclu...

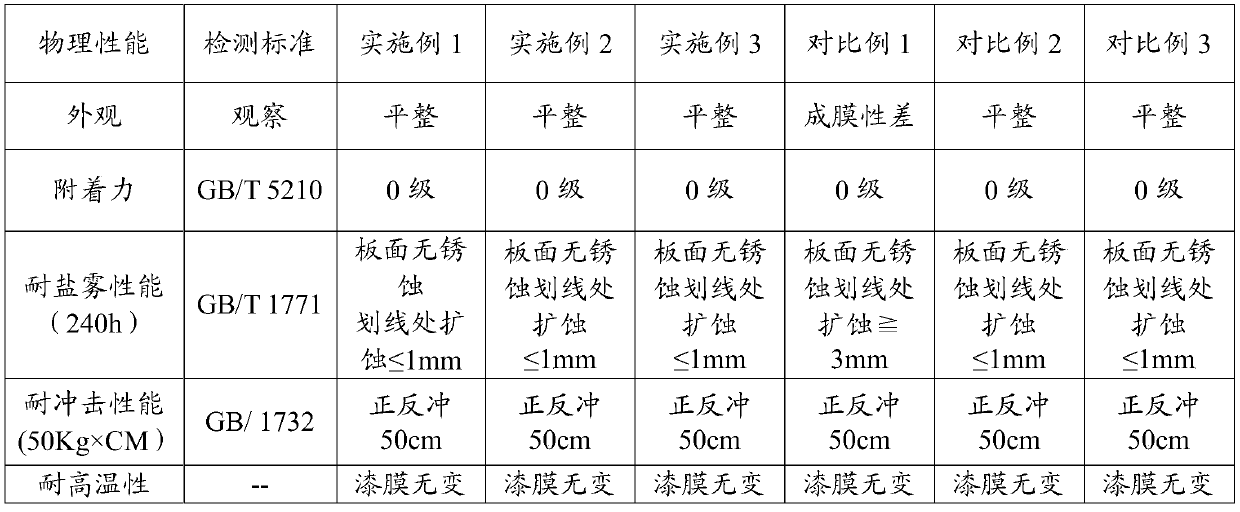

Embodiment 1

[0066] Mix 1.5g of dilute nitric acid solution (the concentration of nitric acid is 0.5mol / L) with 30g of silica sol (purchased from Grace Company, pH=8.0) to adjust the pH value to 3.0, add 10g of nano-silica dispersion (purchased from Shaoxing Yu up to chemical industry) to stir evenly to obtain the first mixture. Add 20g of siloxane (purchased from Dow Corning Co.) into a three-necked flask, reflux and condense, add the first mixture dropwise under stirring conditions, react at 80°C for 8 hours after the dropwise addition, cool to room temperature, and add to the obtained Add 5 g of ethylene glycol to the mixed solution to obtain the second mixture. Then add 2g dispersant BYK-165 (purchased from Lubrizol Company), 1g anti-sedimentation agent bentonite (purchased from Degussa Company, R972), 3g attapulgite (purchased from Changzhou) to the second mixture under the condition of stirring Naou Technology), 10g glass powder (purchased from Xianyang Yinghe, 2000 mesh) and 30-35g...

Embodiment 2

[0068] Mix 1.8g of dilute nitric acid solution (the concentration of nitric acid is 0.5mol / L) with 43g of silica sol (purchased from Grace Company, pH=8.0) to adjust the pH value to 3.0, add 10g of nano-silica dispersion (purchased from Shaoxing Yu up to chemical industry) to stir evenly to obtain the first mixture. Add 20g of siloxane (purchased from Dow Corning Co.) into a three-necked flask, reflux and condense, add the first mixture dropwise under stirring conditions, react at 80°C for 8 hours after the dropwise addition, cool to room temperature, and add to the obtained Add 5 g of ethylene glycol to the mixed solution to obtain the second mixture. Then add 1.2g dispersant BYK-165 (available from Lubrizol), 2g anti-sedimentation agent bentonite (available from Degussa, R972), 2g attapulgite (available from Changzhou Naou Technology), 5g glass powder (purchased from Xianyang Yinghe, 2000 mesh) and 30g Fe 3 o 4 -Graphene-SiO 2 Composite nanoparticles (see Example 1) are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com