Preparation method of VS2/CdS composite photocatalyst

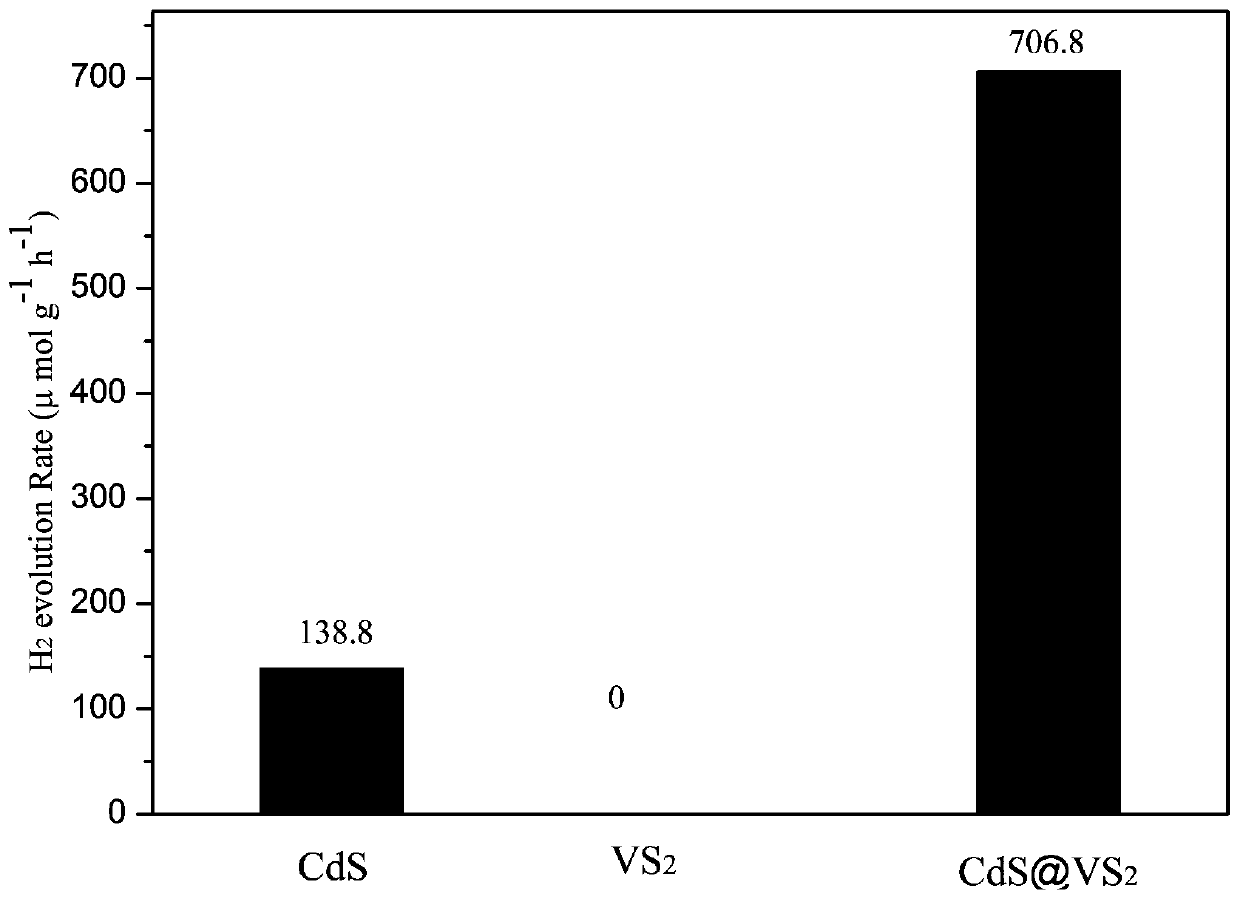

A technology of catalyst and composite light, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of inhomogeneous distribution, unfavorable large-scale promotion, expensive precious metals, etc., and achieve accelerated migration rate. , The effect of improving photocatalytic performance and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

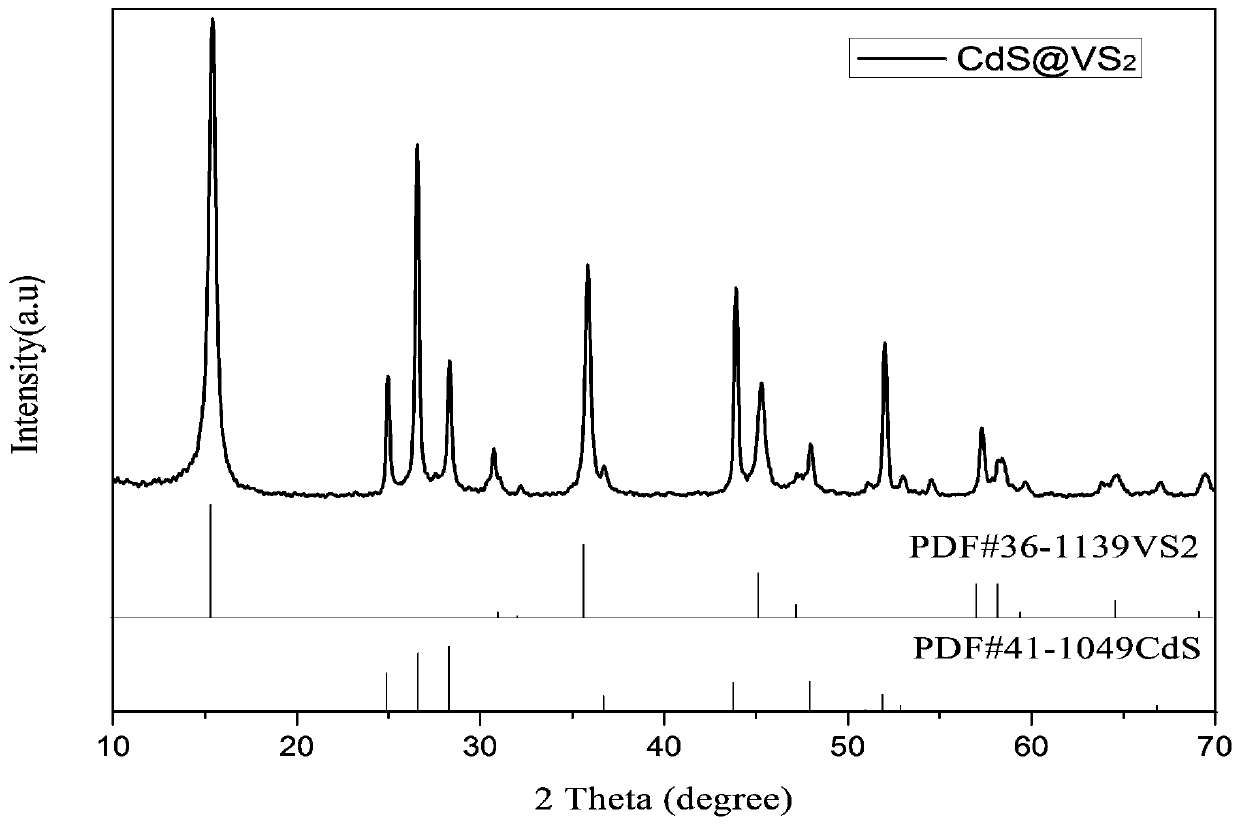

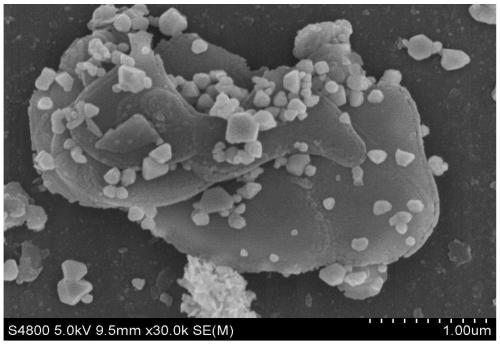

[0027] A VS 2 The preparation method of / CdS composite photocatalyst comprises the following steps:

[0028] Step 1: Take 0.5mol cadmium acetate, 2mol ammonium metavanadate, and 8mol thioacetamide and mix to obtain a mixture;

[0029] Step 2: Add 40ml of deionized water to the mixture and stir magnetically for 15min at a rotating speed of 500r / min. At this time, the concentration of cadmium ions is 0.0125mol / L, the concentration of vanadium ions is 0.05mol / L, and the concentration of sulfide ions 0.2mol / L; then add 8ml of ammonia water and stir magnetically at 500r / min for 0.5h to obtain solution A;

[0030] Step 3: Put the solution A into the polytetrafluoroethylene liner and seal it and place it in the reactor in a homogeneous reactor, and conduct a hydrothermal reaction at 140°C for 18 hours. During this process, vanadium ions combine with sulfide ions to form disulfide Vanadium, cooled to room temperature; secondary hydrothermal reaction at 170°C for 5 hours, during this ...

Embodiment 2

[0034] A VS 2 The preparation method of / CdS composite photocatalyst comprises the following steps:

[0035] Step 1: Take 1mol cadmium acetate, 3mol ammonium metavanadate, and 9mol thioacetamide and mix to obtain a mixture;

[0036] Step 2: Add 45ml of deionized water to the mixture and stir magnetically for 15min at a rotating speed of 600r / min. At this time, the concentration of cadmium ions is 0.0222mol / L, the concentration of vanadium ions is 0.0667mol / L, and the concentration of sulfide ions 0.2mol / L; then add 9ml of ammonia water and stir magnetically at 600r / min for 1h to obtain solution A;

[0037] Step 3: Put solution A into a polytetrafluoroethylene liner and seal it and place it in a reactor in a homogeneous reactor, and conduct a hydrothermal reaction at 145°C for 19 hours. During this process, vanadium ions combine with sulfide ions to form disulfide Vanadium, cooled to room temperature; secondary hydrothermal reaction at 175°C for 6 hours, during this process, c...

Embodiment 3

[0040] A VS 2 The preparation method of / CdS composite photocatalyst comprises the following steps:

[0041] Step 1: Take 1.5mol cadmium acetate, 3.5mol ammonium metavanadate, and 9.5mol thioacetamide and mix to obtain a mixture;

[0042] Step 2: Add 50ml of deionized water to the mixture and stir magnetically for 20min at a speed of 700r / min. At this time, the concentration of cadmium ions is 0.03mol / L, the concentration of vanadium ions is 0.07mol / L, and the concentration of sulfide ions 0.19mol / L; then add 9ml of ammonia water and magnetically stir for 1h at a speed of 700r / min to obtain solution A;

[0043] Step 3: Put solution A into a polytetrafluoroethylene liner and seal it and place it in a reactor in a homogeneous reactor, and conduct a hydrothermal reaction at 150°C for 20 hours. During this process, vanadium ions combine with sulfide ions to form disulfide Vanadium, cooled to room temperature; secondary hydrothermal reaction at 170 ° C for 7 hours, during which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com