Preparation method of aged modified zero-valent iron and method for degrading chlorinated organic pollutants by using aged modified zero-valent iron

A technology of organic pollutants and zero-valent iron, which is applied in the field of chemistry to achieve the effect of improving reactivity, enhancing reactivity and improving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

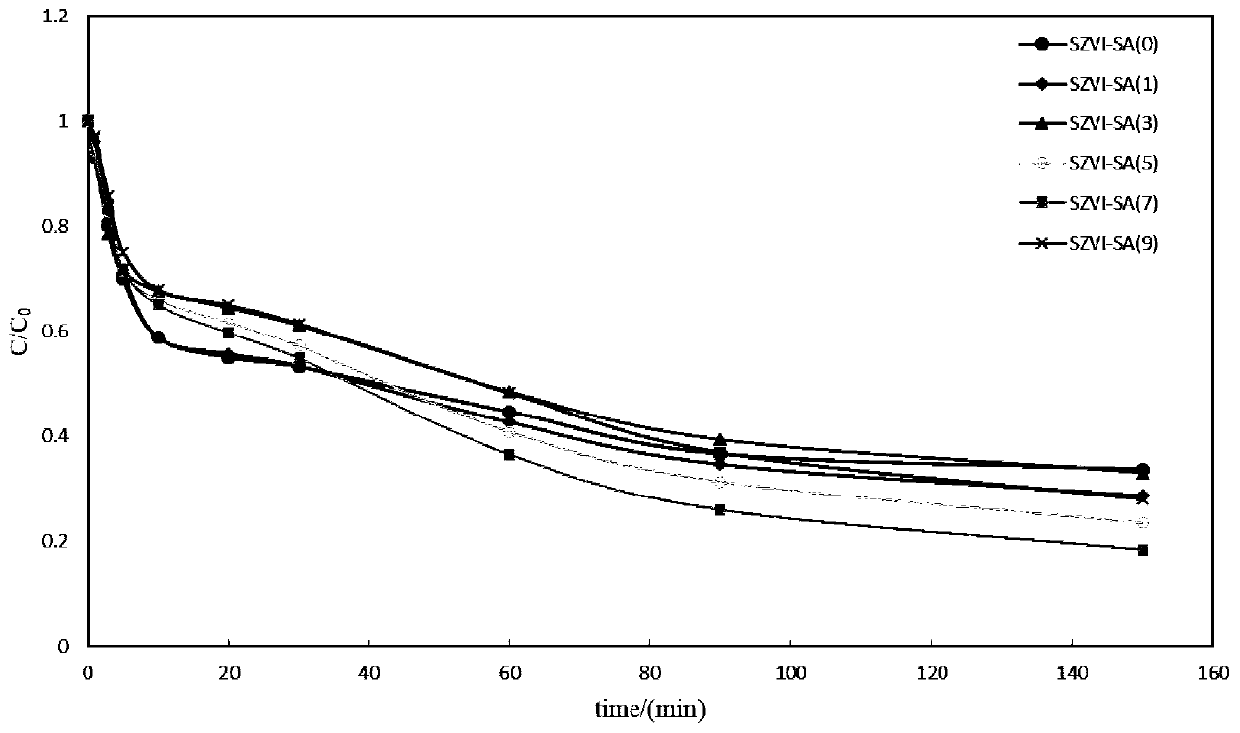

[0026] Embodiment 1: This embodiment provides a method of aging and modifying zero-valent iron material to improve the activity of the material, and at the same time using the aged-modified zero-valent iron to degrade chloramphenicol-containing wastewater under aerobic conditions.

[0027] The room temperature is 18°C, add 250ml of acetic acid-sodium acetate buffer solution to the 250ml reaction bottle, control its pH between 5.5-6.5, blow nitrogen to reduce the dissolved oxygen to 0, add 1g of zero-valent iron with a particle size of 70-80 microns Powder, ultrasonic for 5 minutes, the ultrasonic spectrum is 40kHz.

[0028] Then add 0.5ml of 1M sodium sulfide solution, place on a shaker and shake at 200rpm for 5-30 minutes, take it out, shake well, filter with suction and freeze-dry at -40°C for 1 hour to obtain the modified zero-valent iron product.

[0029] The above materials were placed in a nitrogen atmosphere at 25°C, and the humidity was controlled at 35%, for 24 hours....

Embodiment 2

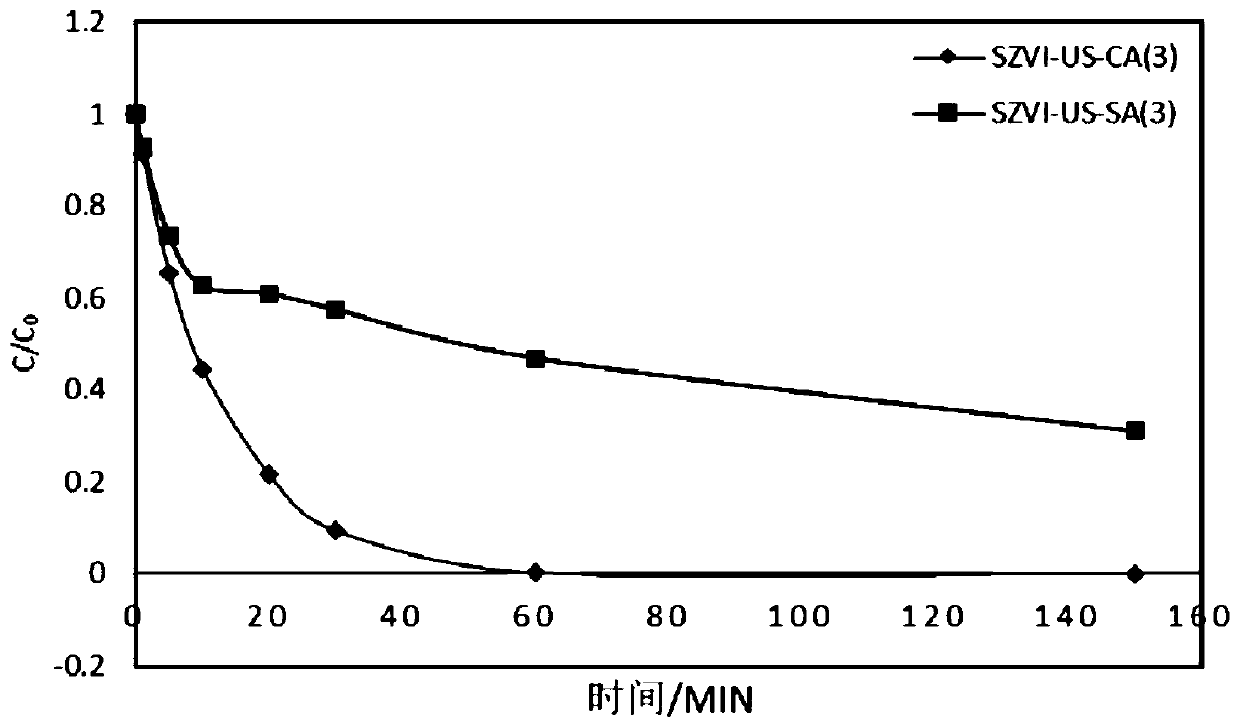

[0033] Example 2: The room temperature is 18°C, add 250ml of acetic acid-sodium acetate buffer solution to a 250ml reaction bottle, control its pH between 5.5-6.5, blow nitrogen to reduce the dissolved oxygen to 0, add 1g of 70-80 micron particle size Supersonicated zero-valent iron powder for 5 minutes, then added 0.5ml of 1M sodium sulfide solution, placed on a shaker at 200rpm for 5-30 minutes, took it out, shook it well, filtered it with suction and freeze-dried for 1 hour to obtain the modified zero-valent iron product .

[0034] Put the modified zero-valent iron in a nitrogen atmosphere at 15-25°C, control the humidity at 60%, and let it stand for 24 hours. Then take it out in the air, keep the air temperature at 20°C, and the air humidity at 35%, and age for 7 days to obtain aged modified zero-valent iron.

[0035]At room temperature, add 500 mL of deionized water to two 500 mL reaction vessels respectively, stir with a mechanical stirrer, control the rotation speed at...

Embodiment 3

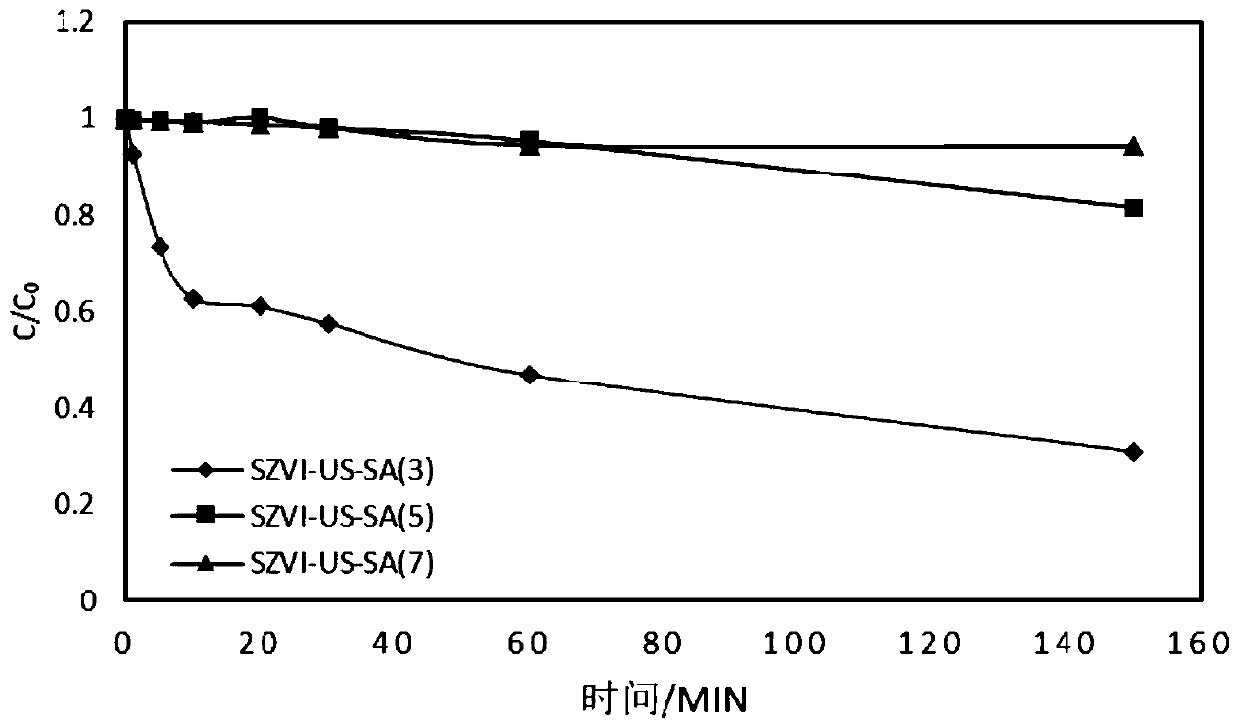

[0036] Example 3: The room temperature is 18°C, add 250ml of acetic acid-sodium acetate buffer solution to a 250ml reaction bottle, control its pH between 5.5-6.5, blow nitrogen to reduce the dissolved oxygen to 0, add 1g of 70-80 micron particle size Supersonicated zero-valent iron powder for 5 minutes, then added 0.5ml of 1M sodium sulfide solution, placed on a shaker at 200rpm for 5-30 minutes, took it out, shook it well, filtered it with suction and freeze-dried for 1 hour to obtain the modified zero-valent iron product .

[0037] The modified zero-valent iron was placed in a nitrogen atmosphere at 25°C and the humidity was controlled at 80% for 24 hours. Then take it out in the air, keep the air temperature at 20°C, and the air humidity at 35%, and age for 7 days to obtain aged modified zero-valent iron.

[0038] At room temperature, add 500 mL of deionized water to three 500 mL reaction vessels respectively, stir with a mechanical stirrer, control the speed at 100 r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com